Manufacturing High-Quality Cast Iron Cookware for Culinary Enthusiasts and Professionals

The Art and Craft of Cast Iron Pan Manufacturing

Cast iron pans have been a staple in kitchens around the world for centuries, renowned for their durability, heat retention, and versatility. The process of manufacturing cast iron pans is a blend of art and science, resulting in cookware that not only performs exceptionally well but also carries a rich heritage of craftsmanship. In this article, we’ll explore the fascinating world of cast iron pan manufacturing, from the raw materials to the final product that graces kitchen countertops and dining tables alike.

Understanding Cast Iron

Cast iron is an alloy primarily made of iron, combined with a small percentage of carbon (typically around 2% to 4%). This combination gives cast iron its unique characteristics excellent thermal conductivity, high heat retention, and exceptional durability. The raw materials used for making cast iron include iron scrap, pig iron, and alloys, which are melted down in a furnace and poured into molds to form various shapes, including skillets, Dutch ovens, and griddles.

The Manufacturing Process

1. Melting and Pouring The manufacturing process begins in a foundry where iron scrap and pig iron are melted in a cupola or an induction furnace. When the iron reaches a molten state, it can be poured into specially designed molds. These molds are often made from sand, which allows for flexibility and detail in the shape of the pan.

2. Molding The molds are typically reusable, formed from sand and clay mixtures, which can withstand the high temperatures of molten iron. Different designs can be made by altering the molds, allowing for various sizes and shapes of pans. The molding process must be precise, as any imperfections will affect the final product.

3. Cooling and Finishing After pouring, the molten iron must cool and solidify in the mold. This can take several hours, depending on the size and thickness of the pan. Once cooled, the cast iron pans are removed from the molds and may undergo additional processes such as grinding, sanding, or polishing to remove any rough edges or imperfections. This attention to detail ensures that each piece not only looks aesthetically pleasing but also functions flawlessly.

cast iron pan factory

4. Pre-Seasoning Before reaching consumers, cast iron pans are typically pre-seasoned. This involves applying a thin layer of oil and heating the pan to create a non-stick surface and enhance its resistance to rust. This step is crucial because it prepares the pan for immediate use and sets the foundation for proper seasoning that can be built over time with regular use.

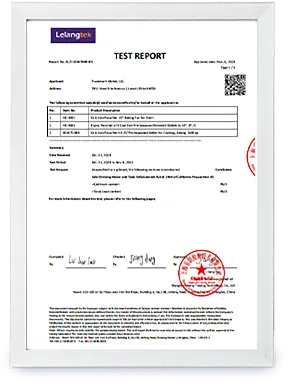

Quality Assurance

Quality control is an integral part of the manufacturing process. Each cast iron pan undergoes rigorous testing to ensure it meets industry standards for durability and performance. Manufacturers often employ skilled artisans who inspect each piece for defects and finish irregularities. This traditional craftsmanship, passed down through generations, is what sets high-quality cast iron pans apart from mass-produced alternatives.

Sustainability and Innovation

In recent years, there has been a growing focus on sustainability within the cookware industry. Many cast iron pan manufacturers are now utilizing recycled materials and eco-friendly practices to minimize their environmental footprint. Innovations in design and production techniques have also led to the development of lighter, more versatile pans that maintain the traditional benefits of cast iron while catering to the needs of modern cooks.

Conclusion

The manufacturing of cast iron pans is a harmonious blend of tradition, craftsmanship, and modern innovation. These sturdy kitchen companions not only offer superior cooking capabilities but also embody the artistry and skill of the artisans who create them. As consumers become more conscious of their choices, the demand for high-quality, sustainably-made cast iron cookware continues to rise. By understanding the intricate processes involved in their creation, we can appreciate not only the beauty of cast iron pans but also the dedication and craftsmanship required to produce them—a true testament to culinary heritage. Whether sautéing vegetables, baking cornbread, or searing a steak, a well-crafted cast iron pan is an heirloom that can be passed down through generations, making it an essential item for any kitchen.

-

Season Cast Iron Perfectly with GPT-4 Turbo TipsNewsAug.01,2025

-

High Quality Cast Iron Cookware - Baixiang County Zhongda MachineryNewsAug.01,2025

-

Premium Cast Iron Pan: Durable & Perfect HeatNewsAug.01,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware Pancake Crepe Pan-Baixiang County Zhongda Machinery Manufacturing Co., Ltd.NewsAug.01,2025

-

Cast Iron Cookware - Baixiang County Zhongda Machinery | Nonstick, Heat ResistanceNewsAug.01,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware - Baixiang County Zhongda Machinery | Non-Stick, Heat Retention, DurableNewsJul.31,2025