Exploring the Craftsmanship of a Cast Iron Pan Manufacturing Facility

The Art of Crafting Cast Iron Pans A Journey to the Heart of a Factory

In recent years, there has been a resurgence of interest in cast iron cookware. From gourmet restaurants to home kitchens, the allure of cast iron pans—renowned for their durability, heat retention, and ability to improve with age—has captivated chefs and home cooks alike. This fascination has brought attention to the factories where these heavy-duty cooking tools are meticulously crafted. A visit to a cast iron pan factory offers a unique glimpse into a world where tradition meets innovation in the art of cookware manufacturing.

At the heart of a cast iron pan factory is a commitment to quality and craftsmanship. The process begins with raw materials. Cast iron is primarily made from iron, with varying percentages of carbon, which gives the pans their characteristic sturdiness and excellent heat conductivity. Workers often utilize recycled scrap iron, making the production not only efficient but also environmentally friendly. Once the raw iron is collected, it is melted in large furnaces at temperatures exceeding 2,500 degrees Fahrenheit. This molten metal is then carefully mixed with carbon and other alloying elements to achieve the desired properties.

When the iron reaches the proper consistency, it is poured into sand molds that define the shape of the pan. The molds are intricately designed, with precise measurements to ensure uniformity. Each mold is reusable, allowing for multiple casts while maintaining the same high standards. The art of molding requires skilled artisans who understand the nuances of metalwork. They must monitor the pouring process closely, adjusting as necessary to prevent defects such as air pockets or uneven thickness.

After the iron cools and solidifies, the molds are removed to reveal the raw cast iron pans. At this stage, the pans are rough and unfinished, requiring extensive machining to ensure a smooth cooking surface. Workers utilize high-powered grinders and lathes to refine the shape and edges, removing any imperfections. This meticulous attention to detail is what sets high-quality cast iron pans apart from their inferior counterparts.

cast iron pan factory

Once the machining process is completed, the pans undergo a thorough cleaning to remove any residue from the casting process. Afterward, they are seasoned with a layer of vegetable oil, a crucial step that enhances their non-stick properties and prevents rust. Seasoning is traditionally done in large ovens, where pans are heated to high temperatures allowing the oil to polymerize and form a protective layer. This process not only prepares the pans for immediate use but also contributes to their longevity, creating a natural patina that improves with each use.

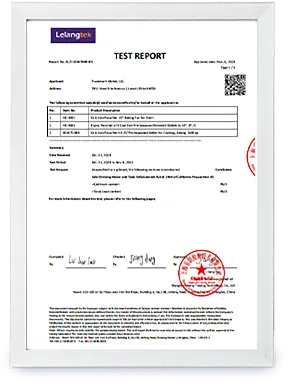

Quality control is paramount in a cast iron pan factory. Each pan is inspected for defects, ensuring that only the finest products reach the market. Artisans conduct rigorous tests, including checking for evenness in thickness and the integrity of the handle. Once a pan passes inspection, it is hand-packed and prepared for shipping. The factory takes pride in its workmanship, knowing that each pan carries a legacy of craftsmanship that can be traced back decades, even centuries.

In addition to traditional production methods, many modern cast iron pan factories are incorporating innovative technologies to enhance efficiency. Automated systems assist in the melting and pouring processes, while computer-controlled machines aid in precision machining. However, the core of cast iron pan production remains rooted in artisanal techniques that have been passed down through generations.

The impacts of these factories extend beyond mere cookware production. They serve as community hubs, providing jobs and supporting local economies. Furthermore, the popularity of cast iron pans has created a culture that values quality cooking at home, encouraging culinary experimentation and a deeper connection to food.

As cooks around the world rediscover the joys of using cast iron pans, the factories behind these products continue to honor their legacy while embracing the future. Each pan tells a story—a narrative woven from tradition, skill, and a passion for cooking that transcends generations. Whether it’s a family recipe passed down through the years or a gourmet dish crafted with care, cast iron pans play an essential role in the kitchen, embodying a timeless love for the culinary arts. In the end, visiting a cast iron pan factory is not just about witnessing production; it’s about connecting with the rich history and artistry that define these beloved kitchen essentials.

-

Season Cast Iron Perfectly with GPT-4 Turbo TipsNewsAug.01,2025

-

High Quality Cast Iron Cookware - Baixiang County Zhongda MachineryNewsAug.01,2025

-

Premium Cast Iron Pan: Durable & Perfect HeatNewsAug.01,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware Pancake Crepe Pan-Baixiang County Zhongda Machinery Manufacturing Co., Ltd.NewsAug.01,2025

-

Cast Iron Cookware - Baixiang County Zhongda Machinery | Nonstick, Heat ResistanceNewsAug.01,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware - Baixiang County Zhongda Machinery | Non-Stick, Heat Retention, DurableNewsJul.31,2025