Premium Large Dutch Oven | Durable Enamel & Ceramic Cookware

Understanding the Modern Large Dutch Oven in Commercial Culinary Operations

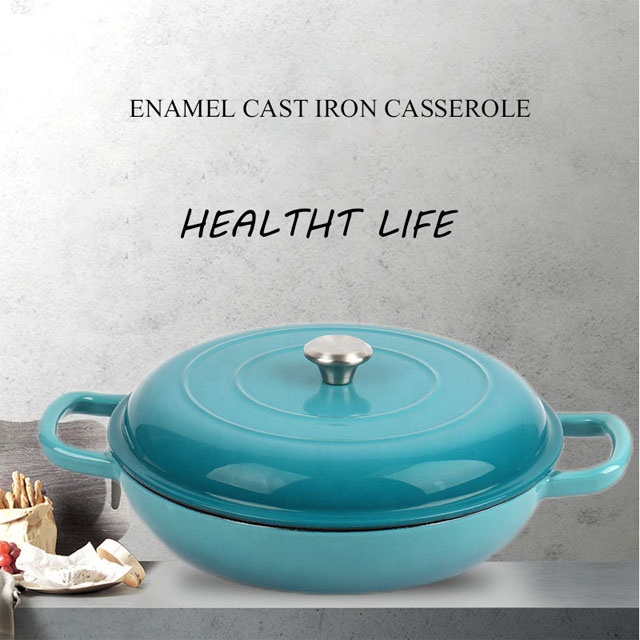

The culinary landscape, particularly in B2B sectors such as hospitality, catering, and institutional food service, demands cookware that offers unparalleled durability, thermal efficiency, and versatility. Central to this requirement is the large dutch oven, a robust cooking vessel designed to handle high-volume demands with consistent performance. These indispensable tools are engineered to excel in various cooking methods, from slow-braising and stewing to baking and deep-frying, making them a cornerstone for professional kitchens. The evolution of materials and manufacturing processes has transformed the traditional Dutch oven into a highly specialized piece of equipment, integrating advanced coatings and precise engineering to meet stringent industry standards for hygiene, longevity, and cooking efficiency. This section explores the inherent value of the modern large Dutch oven, highlighting its essential role in optimizing kitchen workflows and elevating culinary output for businesses worldwide.

Industry trends indicate a growing preference for resilient and multifunctional cookware that can reduce operational costs through energy efficiency and extended product lifespan. The demand for a large dutch oven that can withstand rigorous commercial use, maintain consistent heat distribution, and simplify cleaning processes continues to rise. This demand is particularly pronounced in establishments that prioritize sustainable practices and seek to minimize equipment turnover. Key innovations include multi-layer enamel coatings that enhance non-stick properties and corrosion resistance, alongside ergonomic designs that facilitate easier handling and storage in busy kitchen environments. Understanding these trends is crucial for businesses looking to invest in cookware solutions that offer long-term value and operational superiority.

Manufacturing Excellence: The Craft of a Robust Large Dutch Oven

The production of a high-quality large dutch oven involves a meticulous multi-stage manufacturing process, predominantly relying on cast iron as the core material due to its exceptional heat retention and durability. The journey begins with the precise melting of raw iron, often combined with carbon and silicon, at extremely high temperatures. This molten metal is then poured into sand molds, a traditional casting method that allows for the creation of intricate and robust single-piece structures. After cooling, the rough castings undergo a deburring process to remove any excess material, followed by shot blasting to create a uniform surface ready for the next crucial stage. This foundational casting ensures the structural integrity and even heat distribution characteristic of superior cookware.

Following the casting, the most critical phase for an enamel dutch oven involves the application of multiple layers of vitreous enamel. This involves a precisely controlled spray or dip application of powdered glass particles, which are then fused to the cast iron surface at temperatures exceeding 750°C (1380°F) in specialized kilns. Each layer, typically comprising a base coat and one or more finish coats, is fired individually, ensuring a durable, non-reactive, and aesthetically pleasing finish. This enameling process provides superior corrosion resistance, enhances food release properties, and allows for vibrant color options, critical for both functionality and presentation in commercial settings. Strict quality control protocols, including visual inspection, adhesion tests, and thermal shock resistance evaluations, are implemented throughout to meet international standards such as ISO 9001, ensuring product reliability and a prolonged service life, often exceeding decades with proper care. This rigorous process guarantees that each large dutch oven meets the demanding requirements of professional culinary environments.

Applicable industries benefiting from the robust design and performance of these specialized cooking vessels extend beyond general hospitality. High-volume catering companies, fine dining restaurants, institutional kitchens (hospitals, schools), and specialized food production facilities (e.g., artisanal preserves, slow-cooked meats) rely on the consistent and controlled heat provided by a large dutch oven. Its advantages in typical application scenarios include significant energy savings due to superior heat retention, which allows for lower heat settings and reduced cooking times once the desired temperature is reached. The enamel coating also provides exceptional anti-corrosion properties, preventing rust and chemical reactions with acidic ingredients, thereby ensuring food safety and preserving the integrity of flavors. Furthermore, the robust construction provides resistance to thermal shock, making these units ideal for transitions between various cooking temperatures and environments.

Technical Parameters and Product Specifications

When selecting a large dutch oven for professional use, understanding its core technical specifications is paramount. These parameters directly influence performance, durability, and suitability for specific culinary applications. The following table provides a comprehensive overview of critical specifications common to high-grade large Dutch ovens, often adhering to standards set by organizations like NSF International for food equipment safety and sanitation. Dimensions, capacity, and material composition are key differentiators impacting heat distribution and retention capabilities.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material | Premium Cast Iron core with Multi-layer Vitreous Enamel Coating (often PFOA/PTFE-free) | Cast Iron, Enamel |

| Capacity | Volume suitable for large batch cooking | 5.5 Quarts (5.2 Liters) to 13 Quarts (12.3 Liters) + |

| Diameter (Top Rim) | External measurement across the top | 26 cm (10.2") to 34 cm (13.4") + |

| Weight | Total weight with lid | 6 kg (13 lbs) to 12 kg (26 lbs) + |

| Wall Thickness | Ensures even heat distribution and retention | 3-5 mm |

| Heat Resistance | Maximum oven-safe temperature | Up to 260°C (500°F) |

| Compatibility | Suitable for various cooktops | Induction, Gas, Electric, Ceramic, Halogen, Oven |

| Certification | Food-grade and safety compliance | FDA, LFGB, ISO 9001 (for manufacturer) |

The robust construction of a large dutch oven, particularly those made from enamelled cast iron, translates directly into several technical advantages. The inherent thermal mass of cast iron ensures exceptional heat retention and distribution, eliminating hot spots and allowing for uniform cooking, which is crucial for achieving consistent results in large-batch preparations. The non-reactive enamel surface prevents leaching of iron into food and resists staining, making it ideal for acidic ingredients like tomato sauces or wine-based braises. Furthermore, the design typically includes a heavy, tight-fitting lid that locks in moisture and flavor, facilitating self-basting through condensation, a feature critical for tenderizing meats and vegetables in slow-cooked dishes.

Strategic Sourcing: Comparing Large Dutch Oven Varieties and Manufacturers

When procuring a large dutch oven for commercial applications, an informed comparison between different types and manufacturers is crucial. While cast iron enamel versions dominate the high-end market, businesses might also consider ceramic dutch oven options, or specialized designs. Each material offers distinct advantages and disadvantages concerning thermal properties, maintenance, and cost. Understanding these variations helps procurement managers make strategic decisions aligning with their operational needs and budget constraints.

| Feature | Enamel Cast Iron (e.g., ZD Cookware) | Ceramic | Bare Cast Iron |

|---|---|---|---|

| Heat Retention | Excellent, very even | Good, but slower to heat up/cool down | Excellent, but can be uneven if not seasoned |

| Reactivity with Food | Non-reactive due to enamel coating | Non-reactive | Reactive with acidic foods (requires seasoning) |

| Maintenance & Cleaning | Easy to clean, resistant to rust | Easy to clean, often dishwasher safe | Requires seasoning, prone to rust if not cared for |

| Durability | Extremely durable, but enamel can chip if dropped | Durable, but susceptible to thermal shock and chipping | Highly durable, virtually indestructible |

| Weight | Heavy | Moderate to heavy | Heavy |

| Cost | High initial investment, but long lifespan | Moderate to high | Lower initial investment |

Customization options for a large dutch oven can include specific capacities, tailored dimensions to fit specialized ovens, custom color schemes to align with brand identity, and bespoke branding (e.g., embossed logos for hotel chains). Reputable manufacturers, often with decades of experience, provide comprehensive customization programs supported by advanced CAD/CAM design and CNC machining capabilities for mold creation. For instance, ZD Cookware, leveraging extensive service years in the industry, offers a robust framework for delivering customized solutions that meet unique client specifications, ensuring that the final product integrates seamlessly into existing kitchen operations while upholding the highest quality standards. This level of service is crucial for large-scale operations or brands seeking distinct product lines.

Real-World Application and Client Success Stories

The practical application of a large dutch oven in professional settings highlights its versatility and efficiency. For example, a major hotel chain utilizing these vessels for banquet preparation reported a 15% reduction in cooking time for large meat braises due to the superior heat retention and distribution. This efficiency translated into significant energy savings and improved kitchen productivity during peak hours. Similarly, a gourmet catering service noted enhanced flavor profiles in their slow-cooked dishes, attributing it to the tight-fitting lids and even heat of their enamel dutch oven collection, which minimized moisture loss and concentrated aromas.

Client feedback consistently emphasizes the durability and ease of maintenance as key advantages. One large-scale institutional kitchen, after adopting a fleet of these cookware units, praised their resistance to daily wear and tear and the simplified cleaning process compared to traditional bare cast iron. This directly contributed to reduced labor costs and improved operational hygiene. Such testimonials, alongside independent laboratory test data confirming adherence to FDA food contact material standards and thermal performance benchmarks, serve to reinforce the authority and trustworthiness of high-quality large Dutch ovens in demanding commercial environments. Our commitment to ISO-certified manufacturing processes ensures every large dutch oven delivered meets global benchmarks for quality and reliability.

Ensuring Trust: FAQ, Support, and Warranty

Building trust in B2B partnerships extends beyond product quality to encompass comprehensive support and clear commitments. Manufacturers of high-end commercial cookware understand the critical role these elements play in a long-term relationship. Here we address frequently asked questions, outline our support mechanisms, and detail our robust warranty structure for the large dutch oven.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a bulk order of large Dutch ovens?

A: Our standard delivery cycle for bulk orders typically ranges from 4-6 weeks, depending on the customization requirements and order volume. Expedited options are available upon request for urgent requirements. -

Q: Are these Dutch ovens suitable for induction cooktops?

A: Yes, all our cast iron enamel dutch oven models are fully compatible with induction, gas, electric, ceramic, and halogen cooktops, as well as oven-safe up to 260°C (500°F). -

Q: How do your large Dutch ovens compare to small dutch oven or mini dutch oven variants in terms of material and durability?

A: While the fundamental material (enameled cast iron) and manufacturing quality are consistent across our range, large Dutch ovens are engineered with reinforced structures to manage greater weight and volume, making them even more robust for continuous, heavy-duty commercial use compared to their smaller counterparts. -

Q: What is the recommended cleaning procedure for these units?

A: We recommend hand washing with warm soapy water and a soft sponge. While the enamel is durable, abrasive scrubbers or harsh detergents should be avoided to preserve the coating's integrity.

Warranty and Customer Support

We stand by the exceptional quality and durability of our products. Each large dutch oven comes with a limited lifetime warranty covering manufacturing defects under normal commercial use. Our dedicated customer support team is available to assist with any inquiries, from product selection and technical specifications to after-sales service and maintenance guidance. We pride ourselves on responsive and knowledgeable assistance, ensuring minimal downtime for your operations. Our commitment to excellence extends throughout the product lifecycle, providing peace of mind for our B2B clients.

References

- National Sanitation Foundation (NSF) International. Food Equipment Standards.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- U.S. Food and Drug Administration (FDA). Regulations for Food Contact Materials.

- American Society for Testing and Materials (ASTM International). Standards for Metals and Coatings.

-

High Quality Cast Iron Cookware - Baixiang County Zhongda Machinery Manufacturing Co., Ltd.NewsAug.12,2025

-

Black Round Cast Iron Cookware - Baixiang County Zhongda Machinery | Non-Stick, Heat RetentionNewsAug.12,2025

-

Black Round Cast Iron Cookware Pancake Crepe Pan-Baixiang County Zhongda Machinery Manufacturing Co., Ltd.|Nonstick Surface&Even Heat DistributionNewsAug.11,2025

-

Durable Cast Iron Camp Dutch Oven for Outdoor CookingNewsAug.11,2025

-

High Quality Cast Iron Cookware - Baixiang County Zhongda Machinery | Non-Stick, Heat RetentionNewsAug.11,2025