cast iron pan factory

The Art of Crafting Cast Iron Pans A Journey Through a Cast Iron Pan Factory

Cast iron cookware has long been celebrated for its durability, heat retention, and versatility, making it a staple in kitchens around the world. At the heart of this culinary tradition lies the cast iron pan factory, where skilled artisans and advanced technologies converge to create the exceptional cookware that many chefs and home cooks cherish.

The Foundations of Cast Iron Manufacturing

At the beginning of the manufacturing process is the selection of raw materials. High-quality pig iron, scrap iron, and alloying elements like carbon are procured from reputable suppliers. These materials are melted down in a large blast furnace, reaching temperatures exceeding 2,700 degrees Fahrenheit (1,480 degrees Celsius). This intense heat transforms the solid metal into a molten state, ready to be shaped into functional pieces of art.

Once the molten iron is ready, it is poured into sand molds, which are meticulously crafted to form the desired shapes of the pans. Sand casting, the traditional method for creating cast iron cookware, provides precision and detail to each piece. The molds are designed to capture the unique features of cast iron cookware, such as the distinctive cooking surface and the handle design.

The Molding Process

The molding process is crucial in determining the quality of the finished product. The molds are created using a mixture of fine sand and clay, which allows for detailed impressions of the pans. Skilled workers carefully pack the sand mixture into the casting boxes that form the molds. After the molds are prepared, the molten iron is poured in, filling every nook and cranny to create a solid and well-defined pan.

Once the metal has cooled and solidified, the molds are broken apart to reveal the rough castings. At this stage, the pans may still have sharp edges and rough surfaces that need to be refined. This is where skilled artisans come into play, as they use various tools to grind, polish, and smooth out the surfaces, ensuring that each pan meets the factory’s quality standards.

cast iron pan factory

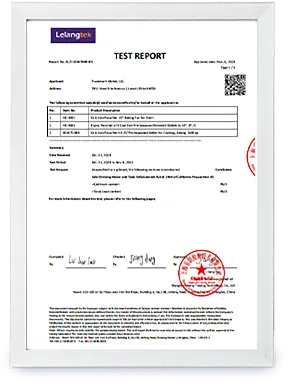

Quality Control and Testing

Quality control is a critical aspect of the cast iron pan manufacturing process. After the initial shaping and polishing, each pan undergoes rigorous testing to ensure it meets the specifications for durability and performance. This may involve checking for defects, testing the heat distribution, and ensuring the non-stick property is consistent across all products.

Moreover, many manufacturers have begun to embrace new technologies, including computer simulations and advanced quality assurance systems, to enhance the production process. These innovations not only increase efficiency but also help in producing pans that are consistently of high quality.

Seasoning The Final Touch

After passing the quality checks, the cast iron pans are seasoned. This process involves applying a layer of vegetable oil and then baking it at high temperatures. Seasoning creates a natural non-stick surface and helps to protect the pans from rust, enhancing their longevity. The seasoning also contributes to the development of the unique patina that cast iron cookware is famous for, allowing each pan to develop its character over time with use.

Conclusion

The journey of a cast iron pan from raw materials to the finished product is a testament to both craftsmanship and modern manufacturing techniques. Each pan reflects the care and dedication put into its creation, ensuring that it will serve its purpose in kitchens for generations. Whether sizzling steaks, baking cornbread, or preparing savory stews, cast iron pans offer an unmatched cooking experience, making them cherished tools in culinary practices around the globe. As consumers increasingly appreciate the art of cast iron, the dedicated efforts of cast iron pan factories continue to play a pivotal role in preserving this culinary heritage.

-

High Quality Kitchen Durable Black Round Cast Iron Cookware - Baixiang County Zhongda Machinery Manufacturing Co., Ltd.|Non-Stick & Even Heat DistributionNewsAug.11,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware Pancake Crepe Pan - Baixiang County Zhongda Machinery Manufacturing Co., Ltd.NewsAug.10,2025

-

Enameled Cast Iron Pot: Durable Dutch Ovens with LidsNewsAug.10,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware-Baixiang County Zhongda Machinery Manufacturing Co., Ltd.|Nonstick Cooking&Even Heat DistributionNewsAug.10,2025

-

High-Quality Black Cast Iron Cookware-Baixiang County Zhongda Machinery|Non-Stick,Heat-Resistant,DurableNewsAug.10,2025

-

High Quality Kitchen Durable Black Round Cast Iron Cookware-Baixiang County Zhongda Machinery Manufacturing Co., Ltd.|Non-Stick Heat RetentionNewsAug.09,2025