...

2025-08-15 07:33

1027

...

2025-08-15 07:17

2982

...

2025-08-15 06:33

398

...

2025-08-15 06:31

1402

...

2025-08-15 06:23

838

...

2025-08-15 06:05

1885

...

2025-08-15 06:01

150

...

2025-08-15 05:36

944

...

2025-08-15 05:22

1804

...

2025-08-15 05:18

1985

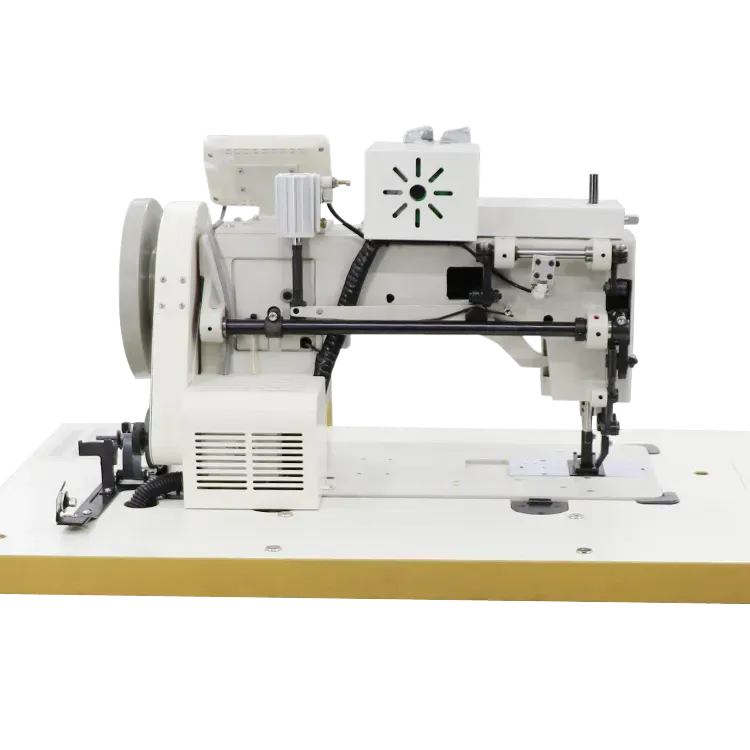

The Importance of Industrial Overlock Sewing Machines in Modern Textiles

Buyers should also consider the potential for used or refurbished cylinder bed sewing machines. The second-hand market can offer significant savings, with prices often reduced by 30-50% compared to new models. However, it is crucial to examine the condition of the machine, verify its maintenance history, and potentially factor in the cost of repairs or refurbishment.

Evolution and Design

1. Durability Industrial sewing machines are built to withstand long hours of operation. The robust construction ensures longevity, making them ideal for businesses that require consistent performance.