The origins of CNC technology can be traced back to the 1940s and 1950s, when engineers began experimenting with automated machine tools. However, it wasn't until the 1980s and 1990s that CNC technology made its way into the sewing industry. The initial machines were bulky and limited in functionality, but as technology progressed, they became more compact and versatile.

Modern long arm heavy duty zigzag sewing machines come equipped with numerous user-friendly features aimed at enhancing the sewing experience. Automatic needle threading, integrated thread cutters, and adjustable stitch lengths and widths make operating the machine a breeze. Furthermore, many machines include a variety of built-in stitches and embroidery capabilities, so users can explore their creativity without needing to invest in additional attachments or accessories.

For those who fear that sewing machines can be intimidating, the New Home Super Automatic Sewing Machine is designed with user friendliness in mind. It features an intuitive interface, often with an LCD screen that guides users through selecting stitches and settings. Many models also come with automatic needle threading capabilities, eliminating one of the more frustrating tasks often associated with sewing.

Additionally, the machine’s design minimizes the likelihood of common sewing issues, such as thread breaking or tension irregularities. Many users report that the Cub Leather Sewing Machine provides consistent performance, allowing them to complete projects efficiently and to a high standard.

The Importance of Jumbo Belt Sew in Modern Fashion

%20(200%20%C3%97%20200%20px)%20(3).webp)

Choosing the best computerized sewing machine can feel overwhelming, especially with the myriad options available in the market today. Whether you are a beginner or an experienced sewer, investing in a high-quality sewing machine can make a significant difference in your sewing projects. Here, we delve into what features to look for and recommend some of the top models available.

The Automatic Buttonhole Sewing Machine A Seamstress’s Best Friend

1. Precision and Consistency One of the most significant advantages of CNC machine sewing is its unmatched precision. Unlike manual sewing, where human error is a constant risk, CNC machines operate on programmed instructions. This ensures that every stitch is uniform, which is particularly critical for high-quality textile production.

4. Pins and Clips To keep your fabric in place while sewing, use pins or fabric clips. This helps ensure straight, even seams.

A double needle sewing machine, as the name suggests, uses two needles working in tandem to create symmetrical stitching. This capability is particularly beneficial for leather projects where strength and visual appeal are crucial. Whether you are crafting bags, jackets, or upholstery, this type of machine offers several advantages that can significantly enhance your leatherworking experience.

Aria, a costume designer, shares, “I switched to a heavy-duty machine two years ago, and it’s transformed my work. I can now handle a wider range of fabrics, and the machine doesn’t falter even with constant use.”

Finally, if you experience issues with the motor or other mechanical components of the machine, it’s best to consult with a professional technician or contact the manufacturer for assistance. Attempting to repair complex mechanical issues without proper knowledge or training can lead to further damage to the machine.

The Benefits and Features of Multi Needle Quilting Machines

Conclusion

What are Strong Sewing Machine Needles?

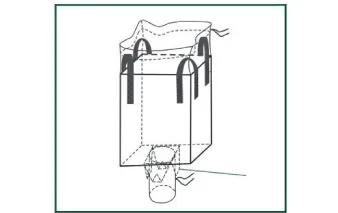

In summary, gunny bag sewing machines are a crucial element of manufacturing operations across various industries. Their ability to enhance efficiency, ensure durability, and contribute to eco-friendly practices makes them indispensable in today’s industrial ecosystem. As the demand for sustainable packaging solutions continues to grow, the role of gunny bag sewing machines in supporting these initiatives becomes ever more significant. As businesses seek to adapt to evolving market trends, investing in such specialized machinery will undoubtedly yield fruitful returns in efficiency and sustainability.

2. Strength and Durability Heavy-duty sewing machines are built to last. Their sturdy construction means they can withstand the pressures of frequent use without wearing down. This longevity makes them a worthwhile investment, especially for those who sew regularly or run a small business.

sewing heavy duty

Another appealing aspect of raised bed sewing machines is their effectiveness in teaching new sewists. Beginners often struggle with handling larger pieces of fabric, and the raised bed design can simplify the learning process. With ample space, it becomes easier to focus on mastering basic techniques without the added challenge of fabric management. This can encourage more individuals to explore sewing as a hobby, ultimately expanding the craft community.

A handheld sewing machine designed for thick fabrics is a game-changer for sewing enthusiasts. By offering portability, ease of use, and the capability to tackle tougher materials, these compact devices allow for greater flexibility in sewing projects. Whether you are a beginner or a seasoned sewist, investing in a quality handheld sewing machine can enhance your crafting experience and empower you to bring your creative visions to life. In a world where convenience and efficiency are increasingly valued, a handheld machine proves to be a worthy addition to any sewist's toolkit.

Making Your Choice

3. Versatility Many industrial sewing machines come equipped with various attachments and features that allow for a wide range of sewing techniques. From straight stitching to zig-zag and overlock stitching, these machines can handle diverse sewing projects, making them ideal for quilters, garment makers, and craft enthusiasts.

In conclusion, automatic machine sewing represents a significant leap forward in the textile industry, marrying tradition with innovation. Its ability to enhance production speed, elevate design complexity, and promote sustainability signals a new era for garment manufacturing. As the industry continues to evolve, the focus must remain on balancing technological advancements with the human elements of creativity and craftsmanship, ensuring that the art of sewing thrives in harmony with automation. The future of sewing, much like fashion itself, is poised for exciting transformations, driven by the interplay of technology and design.

Key Features to Look For

8. Attachments and Accessories

Maintaining your machine will ensure that it stays in good condition and works correctly. You should wipe your heavy-duty sewing machine, dust off all the lint, and lose thread after every use. Open the needle plate to access the bobbin and hook area and blow the lint and dust out with compressed air towards a sticky lint brush. Oil your machine regularly with a high-quality sewing machine oil, but only after cleaning the dust and lint off first.

B. Benefits of Heavy Duty Machines:

In this section, we’ll delve into the advantages of using heavy duty sewing machines. We’ll highlight their durability, reliability, and ability to sew through multiple layers of fabric. Additionally, we’ll discuss how heavy duty machines can save time and effort by offering faster stitching speeds.

The Versatility of Coverstitch Chain Stitch in Garment Construction

Hand sewing leather is a timeless skill that combines artistry with craftsmanship. Whether you're creating a bespoke leather bag, wallet, or any other handcrafted item, understanding how to position the needle correctly is crucial for achieving clean, strong stitches. This article will explore the nuances of needle positioning specific to leatherwork, providing you with the essential knowledge to elevate your sewing projects.

Correct Angle and Positioning

Once you have your materials and tools, you can start working with leather. Here are a few basic techniques to master

2. Powerful Motor A heavy duty sewing machine is typically equipped with a strong motor that provides the necessary torque for tackling tough fabrics. This prevents the machine from slowing down or stalling, allowing for a seamless sewing experience.

When tackling thick materials, it’s important to use the right needles and thread. A sewing machine that can accommodate large, robust needles (like a 16 or 18 size) is ideal for heavy fabrics. Similarly, using heavy-duty thread will help prevent breakage and ensure strong seams. Make sure your sewing machine is compatible with such needles and threads.

Several factors contribute to the pricing of fully automatic sewing machines. Brand reputation plays a significant role; well-established brands known for their quality and innovation tend to charge more for their products. Additionally, the complexity of features offered also impacts pricing. Machines with specialized functions, such as quilting capabilities or multi-needle systems for embroidery, will naturally be more expensive due to the technology involved.