Advantages of Using a Walking Foot for Leather

In conclusion, the manual leather stitching machine is a timeless tool that embodies the essence of craftsmanship in leatherworking. Its simplicity, versatility, and ability to create superior quality stitches make it a favored choice for both novice and experienced artisans. By investing the time to learn and refine techniques, crafters can produce beautiful, long-lasting leather goods that are a true testament to their skill and dedication. Whether you are creating handbags, wallets, or bespoke items, mastering the manual leather stitching machine opens up a world of creative possibilities. Thus, it stands as a vital component of the leatherworking tradition, connecting artisans to the rich history of their craft.

Time-Saving Efficiency

2. Adjust Tension Depending on your fabric, you might need to adjust the tension settings. A typical tension range is between 4 and 6. Perform a test stitch on a scrap piece of fabric before starting on your actual project. Adjust the tension as needed until the stitches lay flat and evenly spaced.

Discovering the Best 5% Thread Overlockers for Sale

Applications in Fashion and Textiles

Applications in the Sewing Industry

3. Space-Saving Many modern machines are designed with compact features, making them ideal for facilities with limited space. Their efficiency allows for integration into existing workflows without requiring significant alterations to the production layout.

sling sewing machine. These machines are built to withstand heavy use and can last for many years with proper maintenance. The sturdy construction of the machine ensures that it can handle the high speeds and precision stitching required for professional sewing projects. This durability makes the sling sewing machine a reliable investment for anyone looking to improve their sewing skills.

A double needle sewing machine is a specialized sewing machine equipped with two needles that run in unison. Each needle operates independently but feeds from the same spool of thread. This unique configuration allows the machine to create two parallel rows of stitching, making it ideal for various applications, particularly in garment construction.

Efficiency is another crucial advantage of the New Home Super Automatic Sewing Machine. Many models are equipped with a powerful motor that can handle multiple layers of fabric, making it suitable for projects that involve thicker materials like denim or canvas. This powerful performance helps in reducing the time spent on laboriously sewing similar projects, allowing users to focus on creativity rather than technical difficulties.

new home super automatic sewing machine

Another benefit of automatic quilting machines is their ease of use. While they may seem intimidating at first, automatic quilting machines are designed to be user-friendly and intuitive. Many machines come with pre-programmed designs, making it easy for even beginners to create beautiful quilts. Additionally, these machines often come with a variety of features and settings that can be adjusted to suit a quilter's preferences.

To master the single needle stitch, one must pay attention to several factors correct needle size, thread type, and tension settings. Using the appropriate needle ensures that the fabric is not damaged while stitching. For instance, a sharp needle is necessary for woven fabrics, while a ballpoint needle works best for knits. Similarly, the choice of thread can greatly influence the final outcome. Cotton threads are favored for their strength and compatibility with natural fibers, while polyester threads are often chosen for their durability and colorfastness.

single needle stitch

In terms of maintenance, industrial sewing machines for leather require regular care and attention to ensure optimal performance. This includes cleaning and oiling the machine regularly, as well as replacing needles and other parts as needed. Proper maintenance not only extends the lifespan of the machine but also ensures smooth and efficient sewing.

Zigzag Stitch Versatility

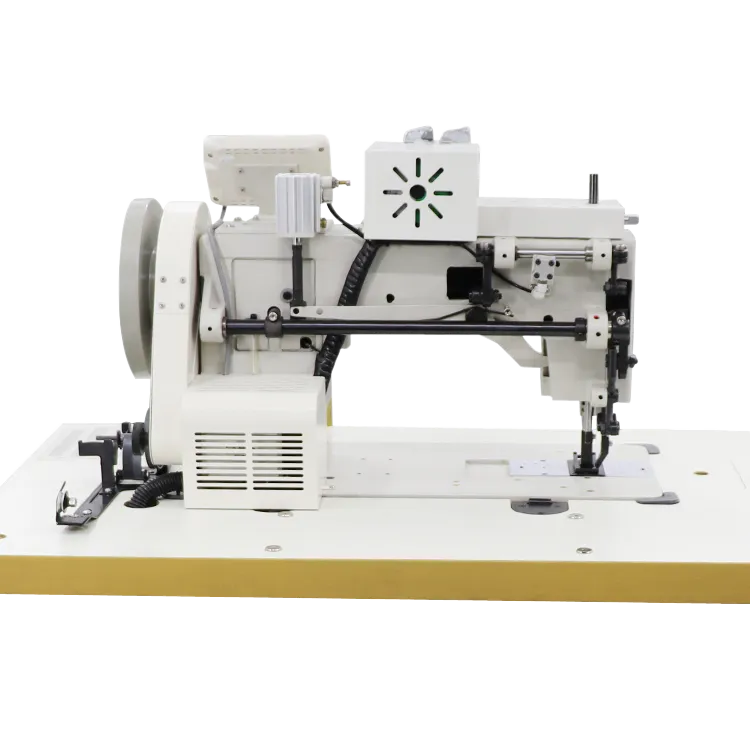

long arm heavy duty zigzag sewing machine

industrial bag sewing machine price. It is important to research and compare different options to find a machine that meets your specific needs and budget. Some factors to consider when choosing an industrial bag sewing machine include the type of bags you will be sewing, the volume of bags that need to be sewn, and the level of automation required.

Before you begin, it’s essential to gather the materials you’ll need a sewing machine that allows the use of a double needle, the appropriate double needle for your fabric type, thread, and fabric.