Insulating tape is also used for color-coding electrical wires. In complex wiring systems, it can be difficult to trace which wire connects to which component. By using different colors of insulating tape to wrap around the wires, technicians can easily identify which wires belong to which circuits. This makes troubleshooting and maintenance much easier and more efficient.

What is Electrical Tape used for?

Electrical Control Boxes

strip seal. These seals are used in hydraulic systems, fuel tanks, and other components to prevent leaks and ensure the safety and performance of the aircraft. Strip seals in aerospace applications must meet stringent requirements for temperature resistance, pressure tolerance, and compatibility with various fluids.

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications 3m self vulcanizing tape.

3m self vulcanizing tape.Several grades of vinyl electrical tape are available — all of which differ in conformability, ease of unwinding, resistance of the adhesive to heat and cold, and loosening (flagging). While general-use vinyl tapes are appropriate for bundling, wire pulling, and other ancillary tasks, premium-grade vinyl tape is the best choice for permanent insulation work as it handles the broadest range of environmental factors and functions, such as cold weather.

Selecting the right tape for your repair project depends on various factors. To make an informed choice, consider the following:

33 kv ht insulation tape.

scotch self amalgamating tape. In the creative industry, designers use it to mock up ideas, creating temporary bonds between materials that can easily be adjusted or replaced. In the automotive sector, it streamlines manufacturing processes by allowing for components to be held together during assembly before being permanently fixed. Even in the world of arts and crafts, this tape provides a reliable solution for model-making and prototyping, where the ability to 'preview' the placement of elements is crucial.

scotch self amalgamating tape. In the creative industry, designers use it to mock up ideas, creating temporary bonds between materials that can easily be adjusted or replaced. In the automotive sector, it streamlines manufacturing processes by allowing for components to be held together during assembly before being permanently fixed. Even in the world of arts and crafts, this tape provides a reliable solution for model-making and prototyping, where the ability to 'preview' the placement of elements is crucial.High Temperature Performance

Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine

Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine automotive wire harness wrapping tape.

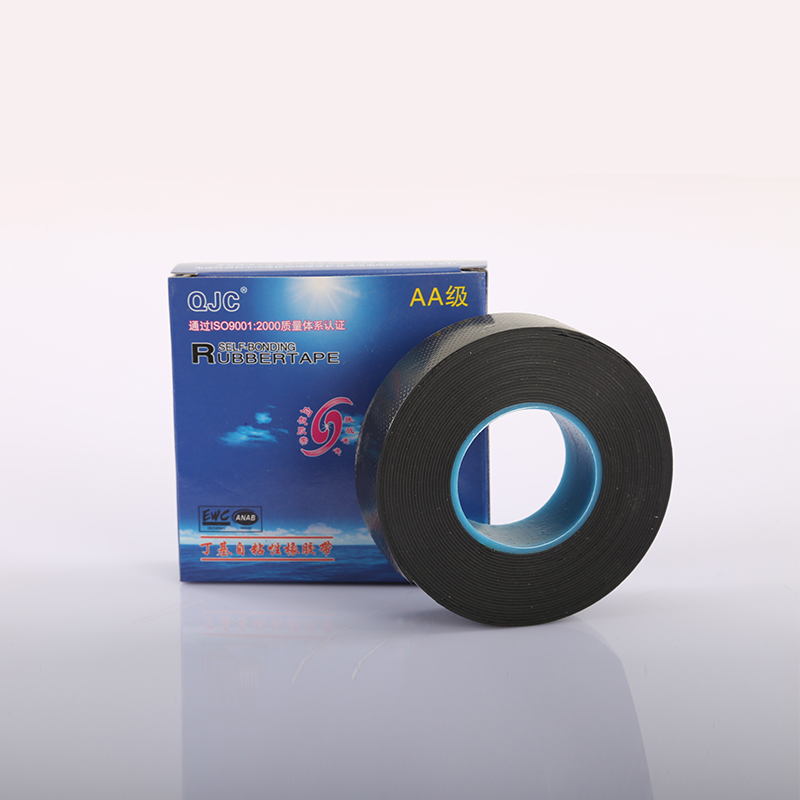

automotive wire harness wrapping tape.The tape fuses or seals itself to create a waterproof and airtight layer when stretched and wrapped around objects.

Modified acrylic

Sealing air pipes

- Roofing Repairs Sealing leaks in roofing systems, protecting against water infiltration, and extending the lifespan of roofs.