For best results, clear any debris or dirt away from the surface to which you’re applying the tape

- One of the key benefits of high-speed splicing tape is its ability to significantly reduce downtime during production processes. Traditional splicing methods often require manual cutting and taping, which can be time-consuming and labor-intensive. With high-speed splicing tape, operators can simply place the tape on the material to be spliced and peel back the liner, creating a strong and reliable bond in a matter of seconds. This not only saves time but also ensures consistent splices that are free from wrinkles, bubbles, or other imperfections.

The table below shows the different features and technical information for our silicone and self-amalgamating tapes.

- 2. Chemical Resistance The tape can withstand exposure to a wide range of chemicals, including acids, bases, and solvents, making it ideal for use in chemical processing plants and other industrial applications.

Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration

Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration Its waterproof barrier not only stops leaks instantly but also prevents future damage by blocking water penetration gray flex seal tape.

gray flex seal tape.

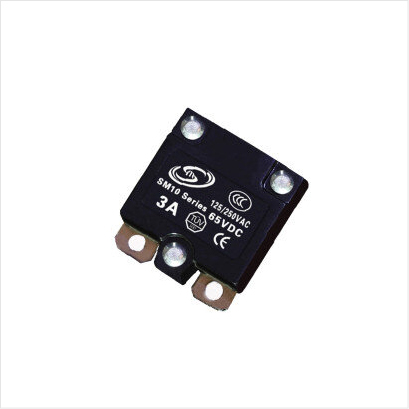

Basics of a Control Box

fireproof sealing strip. It is also crucial to choose the right type and size of the seal for each application to maximize its sealing capabilities.

The tape fuses or seals itself to create a waterproof and airtight layer when stretched and wrapped around objects.

Self-fusing tape is also frequently used in electrical applications. The tape is highly resistant to heat, making it ideal for insulating and protecting electrical wires and connections. It can be used to seal and protect exposed wires, repair damaged insulation, and create a waterproof seal around electrical connections. Self-fusing tape is also often used in automotive applications for repairing hoses, wiring, and other components.

self fusing tape uses

Conclusion