...

2025-08-14 13:31

1231

...

2025-08-14 12:30

2785

...

2025-08-14 12:29

2169

...

2025-08-14 12:27

1939

...

2025-08-14 12:25

958

...

2025-08-14 12:17

1589

...

2025-08-14 11:54

943

...

2025-08-14 11:51

2919

...

2025-08-14 11:38

316

...

2025-08-14 11:25

1674

A) Shaft runout

As shown in Figure 8, shaft runout is defined as being twice the eccentricity between the shaft center and center of shaft-center rotation trajectory.

12 22 5 oil seal. Its ability to resist wear and tear ensures that machinery stays operational for longer periods without the need for frequent maintenance.

35x50x8 oil seal. Common materials used in oil seals include nitrile rubber, silicone, and Viton, each with its own unique properties and applications. Choosing the right material for your oil seal is essential to ensure that it can withstand the operating conditions of your machinery.

35x50x8 oil seal. Common materials used in oil seals include nitrile rubber, silicone, and Viton, each with its own unique properties and applications. Choosing the right material for your oil seal is essential to ensure that it can withstand the operating conditions of your machinery.In choosing the right oil seal type for your application, it is essential to assess factors such as speed, temperature range, pressure levels, chemical compatibility, shaft material, and installation space limitations. By considering these factors carefully, you can ensure that you select an oil seal that will provide optimal performance and longevity in your specific application.

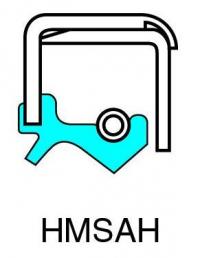

Spring Seals

All are fitted with a spring to preload the sealing lip. All these types are for non-pressurised or low-pressure applications up to 0.5 bar for diameters of a limited size. For diameter of 500 mm or more, the maximum pressure is 0.1 bar. For higher pressures, special types or PTFE lip seals can be used.