- Machinery

- The size of the fence is another decisive element. The larger the area to be fenced, the higher the cost. This not only includes the material cost but also the labor for installation. Moreover, if the terrain is uneven or presents obstacles like trees or rocks, additional work may be needed, which can increase the overall price.

- Artisans and designers continue to push the boundaries of ornamental metalwork, incorporating cutting-edge technology such as laser cutting and 3D printing

Another way of looking at a bottom-hung window opening is as a tilt-and-turn but without the turning facility.

Maintenance of wrought iron gate ornaments is relatively straightforward, which adds to their appeal. Regular cleanings and periodic applications of rust-resistant paint or sealant can keep them looking pristine for years. In climates prone to extreme weather, additional care may be needed to preserve the metal's finish and integrity. However, with proper maintenance, wrought iron can endure for generations, making it a sustainable choice for exterior décor.

1. Climate and environment conditions

- The Unbreakable Alliance Lock & Lock Steel Lunch Box

- Reeded cast iron panels, a timeless architectural element, have been an integral part of design and construction for centuries. These ornate and robust fixtures embody the perfect blend of aesthetics and practicality, reflecting the craftsmanship and creativity of the past while serving a multitude of functional purposes.

- The primary function of heavy duty door rollers is to facilitate the smooth opening and closing of large, heavy doors. Equipped with sturdy materials like stainless steel or hardened iron, they can handle weights that would break conventional rollers. Their robust design not only ensures longevity but also minimizes the strain on the door frame, preventing potential damage over time.

But one of the most fundamental questions is: what material will your fence be made of?

Both types of iron are highly recyclable, which adds to their sustainability. At the end of their life cycle, iron fences can be melted down and reused, reducing the need for new raw materials and minimizing waste.

The strength of a fence or railing will also be greatly influenced by the thickness of the iron and by whether the manufacturer uses solid or hollow components since hollow components are lighter weight and more susceptible to rust and corrosion. we use solid posts for fences and railings and ⅝” solid square vertical pickets. These make our structures very strong: take a trip to our showroom and you’ll be surprised how difficult these components can be to lift because of the sheer mass of metal in their sturdy construction.

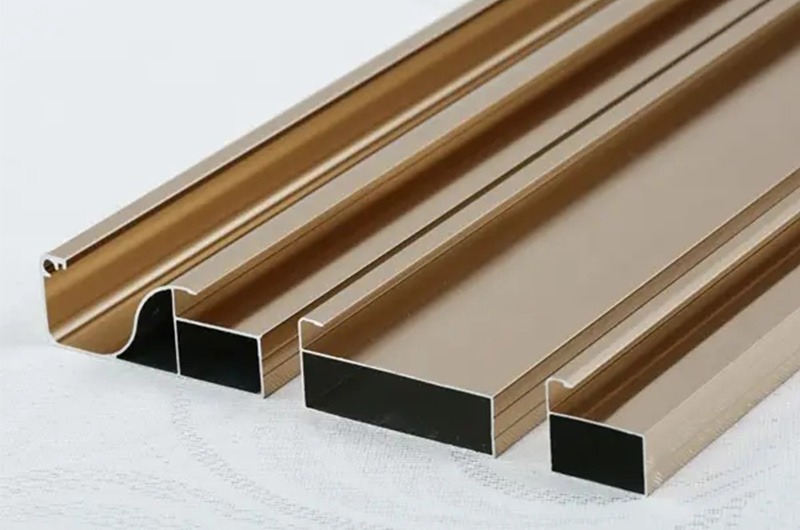

Aluminum profiles require very few maintenance compared to other materials. There is no need for regular painting or treatment, and standard cleaning agents can be used for cleaning and maintenance.

Aluminum fence is easy to install; for DIYers, it’s one of the easiest fences to build! Aluminum offers the look of wrought iron, but it’s lighter in weight and costs significantly less. Aluminum fencing is an incredible option if you like customization—not only can you choose among several grades of fence, with increasing stability for grade; you can also buy it in multiple colors, which many homeowners appreciate as they can create a fence that adds greater visual appeal in their yard. One of the things most DIY experts like is that aluminum fence is also easy to repair should it get damaged as you can replace a single picket versus replacing an entire section of fence. Aluminum is also easy to install and works well in an environment with a bit of a slope as you can rack the panels to adjust with the angle of the ground it covers.

All these features come together to make a wrought iron fence a formidable opponent against unwanted trespassing. It’s one of the premier security fencing solutions for this reason.

Surface finish: This dramatically impacts the performance of doors and windows. If the surface finish is not good, the corrosion resistance, wear resistance, oxidation resistance and other properties of doors and windows may be reduced.

Size: There are two types of door and window profile sizes, one is standard size and the other is customized size. We can make custom sizes according to your project needs.

Quality standards: There are different quality standards for door and window profiles. According to your local requirements, you can refer to the standards of profiles and provide requirements to the manufacturer. Or you can take the profile's weight, appearance, hardness, strength, and oxide film.

thickness as a reference direction and coordinate with the aluminum material manufacturer.

Thickness: This is one of the important indicators of doors and windows, which is directly related to the safety performance of doors and windows. The wall thickness of the main stress-bearing rods of aluminum alloy doors and windows should be more than 1.4 mm. The wall thickness of the main stress-bearing rods of aluminum alloy doors should be more than 2.0 mm. The tensile strength should reach 157N/mm.

Type: There are many types of profiles now which can fully meet the needs of any project. Generally, different use environments will have specific profiles to choose from.

For example:

Standard aluminum door and window profiles

Thermally broken aluminum door and window profiles

Sliding aluminum windows and doors profiles

Casement aluminum windows and doors profiles

Folding aluminum windows and doors profiles

Soundproof aluminum alloy profile

Generally, the profile configuration should be selected according to the project requirements when choosing aluminum materials for doors and windows. If you have special requirements, you can communicate with the aluminum profile manufacturer. Now the technology from extrusion to processing door and window profiles is very mature. As a professional aluminum factory, we have produced aluminum for any project. We are fully confident in producing aluminum for any project.

Conclusion