flat cast iron skillet

The Allure of the 3-Quart Cast Iron Pot

Wycieczka kempingowa z wykorzystaniem statywu i garnka holenderskiego to przepis na udany wypoczynek. Niezależnie od tego, czy jesteś doświadczonym fanem kempingu, czy dopiero zaczynasz swoją przygodę z naturą, te dwa elementy staną się kluczowymi towarzyszami każdej wyprawy. Czas spędzony na świeżym powietrzu, w połączeniu z pysznym jedzeniem, gwarantuje niezapomniane chwile w gronie najbliższych.

When it comes to cooking times, the slow cooker has the upper hand for those who appreciate convenience. You can set it for several hours, and it will keep cooking slowly without any further input. This feature is particularly useful for busy families or individuals who want to come home to a hot, home-cooked meal.

One of the primary advantages of enamel coated frying pans is their non-stick surface. The enamel coating provides a smooth, non-porous surface that prevents food from sticking, allowing for easy cooking and effortless cleanup. This feature is particularly beneficial when preparing delicate foods such as eggs or fish, which often stick to regular pans. With an enamel frying pan, you can say goodbye to the frustration of scraping off burnt-on residue.

Kastestøypanne En Allsidig Kjøkkenvenn

- Maraming Gamit Ang skillet ay hindi lamang para sa pagprito. Maaari rin itong gamitin sa pag-bake, sautéing, at braising. Kung may skillet ka, mas marami kang opsyon sa pagluluto.

Proper cleaning is essential to maintaining a cast iron grill griddle and preserving its seasoning. After each use, allow the griddle to cool slightly, but not completely, before cleaning. Scrape off any food residue with a stiff brush or scraper, then rinse with hot water—avoid using soap, as it can strip the seasoning. If necessary, use a paste of coarse salt and water to scrub off stubborn bits. After cleaning, thoroughly dry the griddle to prevent rust, and apply a thin layer of oil to the surface to maintain the seasoning. Store the griddle in a dry place, preferably with a paper towel or cloth between the cooking surface and the lid to allow air circulation. Proper care will ensure that your cast iron grill griddle remains a reliable and durable cooking tool for years to come.

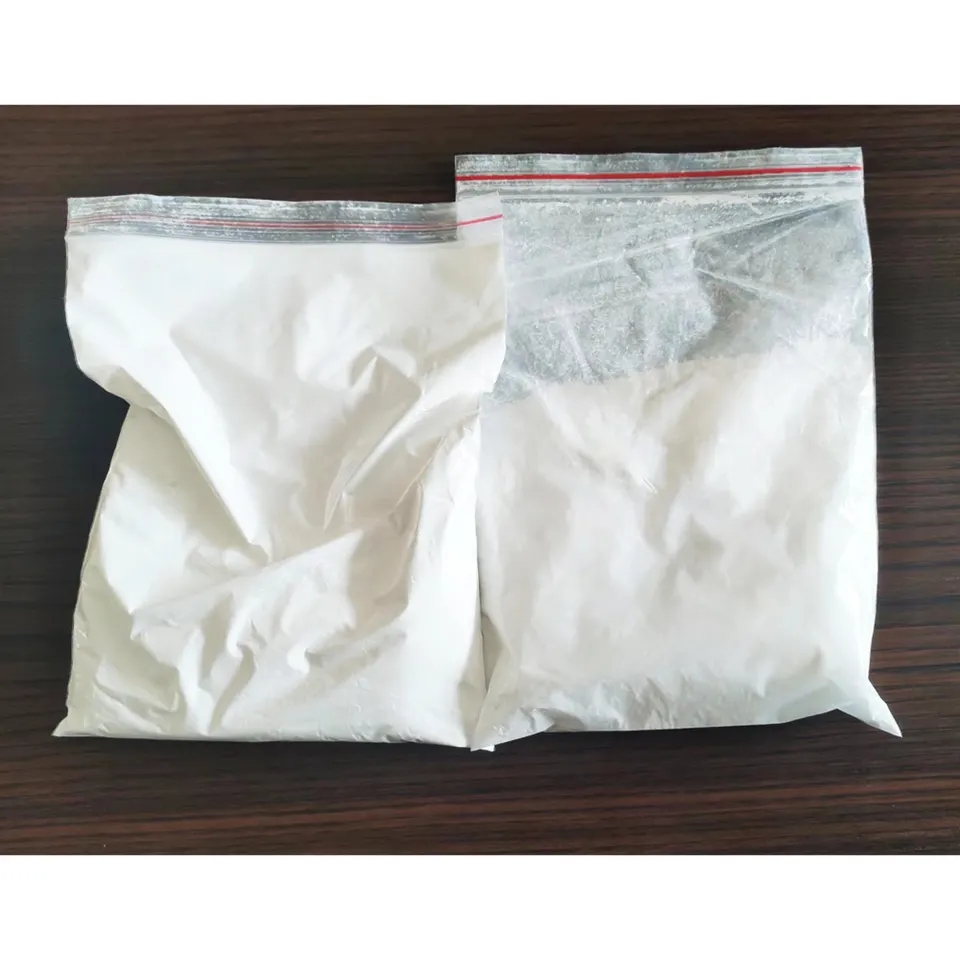

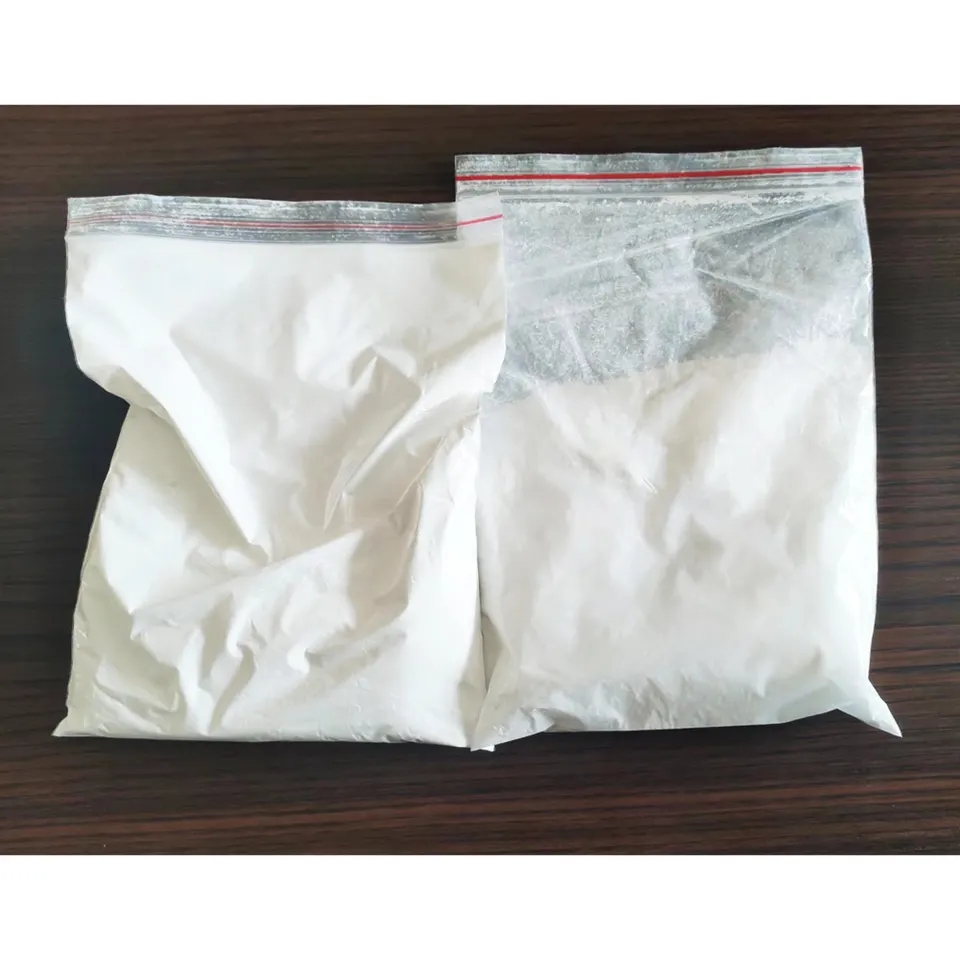

In conclusion, wholesale lithopone MSDS quotes play a crucial role in ensuring the safe and responsible use of this important industrial pigment. By considering key factors such as product information, hazard identification, safety measures, emergency procedures, and regulatory compliance, businesses can make informed decisions when sourcing lithopone for their manufacturing processes. Ultimately, prioritizing safety and regulatory compliance is essential for a successful and sustainable industrial supply chain.

Finally, it's important to consider the global trends impacting the pigment industry as a whole. Environmental regulations, technological advancements, and sustainable practices are increasingly becoming part of the conversation. Suppliers that prioritize eco-friendly production methods or offer biodegradable alternatives may appeal to buyers willing to pay a higher price for sustainably sourced materials.

Neutral

When examining a lithopone pigment pricelist, one might notice that prices can vary significantly between different grades of lithopone. Generally, there are two main types Lithopone 28 and Lithopone 60, with the numbers denoting the percentage of zinc sulfide content. Lithopone 28, with a lower zinc sulfide content, is often more affordable compared to Lithopone 60, which offers superior whiteness and opacity. The choice between these grades depends largely on the specific requirements of the end application.

In conclusion, as a leading manufacturer of nano titanium dioxide, we are proud to offer high-quality products that meet the needs of our customers in a wide range of industries. With our focus on strength, UV resistance, and optical properties, our nano titanium dioxide products are sure to enhance the performance and appearance of a variety of applications. Customers can trust in our commitment to sustainability and environmental responsibility, knowing that they are getting a product that is not only top quality but also eco-friendly.

There is also some evidence to suggest that exposure to titanium dioxide nanoparticles may be harmful or toxic to the environment, including aquatic life and other organisms. The production and disposal of the mineral may also release pollutants, such as carbon dioxide and sulfur dioxide, into the air and water.

In short, no, research demonstrates that E171 is safe when consumed in normal situations.

Moreover, how we're exposed to an ingredient matters significantly in terms of our health and potential toxicity.

Research shows that inhaling titanium dioxide particles in significant quantities over time can cause adverse health outcomes. Unless you work in an industrial setting, inhaling substantial amounts of titanium dioxide is highly unlikely.

Research supports that applying titanium dioxide to the skin in the form of sunscreens, makeup, and other topical products does not pose a health risk.

Overwhelmingly, research that's relevant to human exposure shows us that E171 is safe when ingested normally through foods and drugs (1,2).

Again, other research suggests that E171 could cause harm; however, those research processes did not design their studies to model how people are exposed to E171. Research that adds E171 to drinking water, utilizes direct injections, or gives research animals E171 through a feeding apparatus is not replicating typical human exposure, which occurs through food and medicine consumption.

Read more in-depth about the titanium dioxide risk at go.msu.edu/8Dp5.

These measures include tightened emission standards, increased penalties for non-compliance, and incentives for cleaner production technologies These measures include tightened emission standards, increased penalties for non-compliance, and incentives for cleaner production technologies

These measures include tightened emission standards, increased penalties for non-compliance, and incentives for cleaner production technologies These measures include tightened emission standards, increased penalties for non-compliance, and incentives for cleaner production technologies china dioxide titanium.

china dioxide titanium.Because of its unique pigment and fine-milled texture, titanium dioxide has become popular over the past century in a wide variety of different products. These include adhesives, paints, plastics, rubbers, textiles, inks, ceramics, and even some pharmaceuticals, foods, and hygiene products.

Europe

Tioxide process. This process is similar to that used to produce fumed silicas. Ultra-low particle size titanium dioxide (15-35 nm) is obtained for use as photocatalyst or UV absorber (for instance in sun protective creams).

In order to evaluate the penetration of the nanoparticles, eight adult male Wistar rats (3 months old) were used for the in vivo experiments. The protocol was approved by the local University Committee for animal testing and is in accordance with the Canadian Council on Animal Care (CICUAL-RD-2021–892-E-UNC-DEC#FCQ).