- Moisture and Weather Resistance

- Common Uses of Black Insulation Tape

- The manufacturing process of electrical tape involves several stages. It starts with the selection of raw materials, which are then processed into a thin, flexible film. This film is coated with an adhesive, followed by a process called calendaring, where the tape is passed through rollers to achieve the desired thickness and consistency. After this, the tape is wound onto rolls and undergoes quality control checks to ensure it meets industry standards for conductivity, tensile strength, and temperature resistance.

The Versatile World of Self-Bonding Rubber Tape

If you’re working with live wires, for example, it’s always best to err on the side of caution and use heat-resistant tape instead.

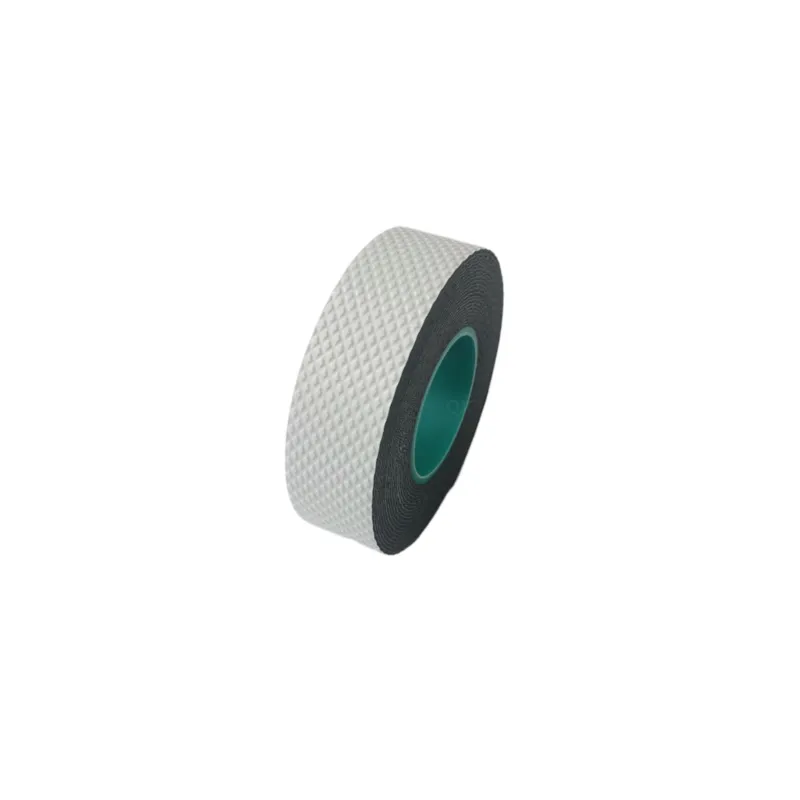

Electrical tapes are typically made with a polyvinylchloride (PVC) backing and a non-corrosive rubber-based adhesive. The backing is what gives it the ability to stretch and conform to cables and wiring. This stretch is a critical characteristic of electrical tapes because it allows the tape to wrap tightly around cables for long-lasting insulation. Most cloth, film, and other types of tapes do not possess the elongation characteristics that allow electrical tapes to function properly.

A well pump control box is basically the brain of a water system because it handles many tasks to keep the system functioning properly.

gray electrical tape. Overlapping layers must be applied without stretching the tape to avoid reducing its insulating effectiveness. Additionally, the tape should not be used as a substitute for proper electrical grounding or as a long-term solution for damaged cords, emphasizing the importance of knowing its limitations.

gray electrical tape. Overlapping layers must be applied without stretching the tape to avoid reducing its insulating effectiveness. Additionally, the tape should not be used as a substitute for proper electrical grounding or as a long-term solution for damaged cords, emphasizing the importance of knowing its limitations.White PVC insulation tape is made from polyvinyl chloride (PVC), a synthetic plastic polymer known for its durability and resistance to moisture and chemicals. The tape has a pressure-sensitive adhesive that allows it to stick securely to a wide range of surfaces. This makes it ideal for insulative applications, where protection against electricity, weather, and wear is essential.

Thin (it is only 0.5mm thick)

Single Phase Start Control Box

warehouse striping tape. This also helps to prevent bottlenecks and congestion in high traffic areas of the warehouse.

Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments

Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments Rubber tape, on the other hand, adheres firmly to surfaces and maintains its grip even in harsh environments