They often invest in research and development to improve the efficiency of their processes and reduce any negative environmental impacts They often invest in research and development to improve the efficiency of their processes and reduce any negative environmental impacts

They often invest in research and development to improve the efficiency of their processes and reduce any negative environmental impacts They often invest in research and development to improve the efficiency of their processes and reduce any negative environmental impacts exporters of titanium dioxide coatings supplier. As such, they are not only critical for the supply chain but also for advancing sustainable practices within the industry.

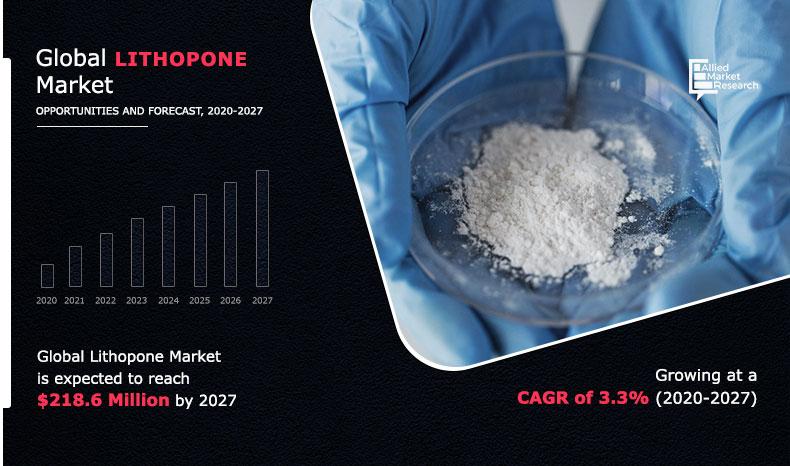

exporters of titanium dioxide coatings supplier. As such, they are not only critical for the supply chain but also for advancing sustainable practices within the industry.In the meantime, the chemical factories of Continental Europe, principally in Germany, Austria and Belgium, had taken hold of the novelty and under the collective name of lithopone or lithophone, by numerous processes, produced various grades of the pigment, branding the respective qualities as red seal, green seal, yellow seal, blue seal, etc., or selling them under some fancy name. Of this we shall speak later on. The crusade against the use of white lead in the various countries of Continental Europe, assisted the manufacturers, to a very great extent, in marketing their products, not only to industrial concerns, as has been the case in this country, until recently, but to the general painting trade. Up to 1889 the imports into this country were comparatively small. At that time one of the largest concerns manufacturing oilcloth and linoleum in the State of New Jersey began to import and use Charlton white. Shortly after that other oilcloth manufacturers followed suit, replacing zinc white with lithopone in the making of white tablecloth, etc., and later on abandoning the use of white lead in floor cloth and linoleum. This gave an impetus to several chemical concerns, that erected plants and began to manufacture the pigment. Competition among the manufacturers and the activity of the importers induced other industries to experiment with lithopone, and the shade cloth makers, who formerly used white lead chiefly, are now among the largest consumers. Makers of India rubber goods, implement makers and paint manufacturers are also consumers of great quantities, and the demand is very much on the increase, as the nature of the pigment is becoming better understood and its defects brought under control. Large quantities find their way into floor paints, machinery paints, implement paints and enamel paints, while the flat wall paints that have of late come into such extensive use owe their existence to the use of lithopone in their makeup.

However, the specific attributes of anatase make it irreplaceable in certain sectors However, the specific attributes of anatase make it irreplaceable in certain sectors

However, the specific attributes of anatase make it irreplaceable in certain sectors However, the specific attributes of anatase make it irreplaceable in certain sectors anatase titanium dioxide producers. For instance, in the field of photovoltaics, anatase titanium dioxide's ability to enhance the efficiency of solar cells is unmatched by other forms.

anatase titanium dioxide producers. For instance, in the field of photovoltaics, anatase titanium dioxide's ability to enhance the efficiency of solar cells is unmatched by other forms.What's the Verdict?

Near sample

A dense, white, opaque pigment composed of a mixture of Zinc sulfide (30%) and Barium sulfate (70%) with trace amounts of Zinc oxide. Lithopone, first produced in 1874, was called Orr's white. The mixture of the two components is so intimate that it is hard to distinguish microscopically. Lithopone is an inert, transparent pigment which is often used as a filler or as a base for lake pigments. Lithopone was widely used in house paints in the first half of the 20th century. It was also used for some artist grounds, inks and as a filler in Paper, Leather, and Linoleum. Now lithopone has mostly been replaced by Titanium dioxide.

The committee could not finalize the assessment of some other flavoring agents, requiring further information. JECFA highlighted the importance of receiving complete data submissions from the sponsors for conducting the safety evaluation.

Stability and darkening

Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses

Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses dioxide titanium b101 anatase powder supplier.

dioxide titanium b101 anatase powder supplier.Where It’s Hiding

The properties of lithopone are very suitable for use in the production of coatings. Because the ingredients of lithopone are zinc sulfide and barium sulfate, and the more zinc sulfide content, the stronger its covering power. This indicates a paint product with strong white covering power. It is different from water in that it reacts with acid but does not react with alkali. It has a wide range of uses. Because its structural properties are similar to titanium dioxide and its price is relatively cheap, it can also be used as a substitute for some titanium dioxide. Lithopone can be used for coloring paints, inks, pigments, rubber, paper, leather, enamel, etc.

In order to contribute with experimental evidence that could help to achieve a better understanding of the field for future regulation, in the present work, the biocompatibility of commercial P25TiO2NPs (one type of TiO2NPs used in sunscreen formulations) and two novel functionalized P25TiO2NPs were evaluated under solar simulated irradiation. White light, generated by red, blue, and yellow LEDs, together with UV ones, was chosen to simulate the solar spectra. Functionalization of TiO2NPs was made with antioxidant vitamins in order to prevent the expected photo-initiated ROS production when nanoparticles are exposed to the simulated solar spectra. Vitamin B2 (riboflavin) and vitamin C were chosen to carry out the functionalization because they are water-soluble, low-cost, and are a constitutive part of biological processes. In addition, it is known that both have the potential to prevent macromolecular oxidation by ROS [23], [24], [25], [26].