1. The surface needs to be clean and dry.Before applying the butyl sealant tape, it is essential to clean the surface where the tape will be applied. Remove any contaminants that can affect the adhesive properties of the tape. Gently scrub the surface with a soft cloth or sponge, and if necessary, utilize a mild cleaning solution. Once complete, make sure to let the area dry completely.

- The versatility of self-adhesive electrical tape extends beyond mere insulation

- 2. Measure and Cut Measure the required length and width of the tape, and use a sharp knife or scissors to cut it to the desired size.

- Butyl foil tape, a seemingly humble material, is a powerful and versatile solution in a myriad of industrial applications. This unique tape is a composite of a butyl rubber adhesive and a metallic foil backing, offering exceptional performance characteristics that make it indispensable in various sectors.

- - **Clean Up After Use** After completing your project, remove any excess tape and clean up the floor surface to prevent tripping hazards.

- Moreover, floor marking tape aids in 5S and lean manufacturing practices by establishing standardized workstations and organizing tools and materials. It helps in maintaining a 'tidy workplace' (Seiri), facilitating 'workplace organization' (Seiton), and ensuring 'standardized work' (Seiketsu), thereby streamlining operations and minimizing waste.

- Moreover, in warehouses, floor marking tape is instrumental in optimizing storage space and ensuring compliance with Occupational Safety and Health Administration (OSHA) guidelines

- Arc flashes, a catastrophic electrical event resulting in intense heat and light, pose a severe threat to human life and infrastructure. Traditional insulation methods often fall short in preventing or mitigating these accidents. However, the advent of Arc Proof Tape has significantly altered this scenario.

- In an increasingly safety-conscious world, fire-resistant foam tape has emerged as a crucial component in the prevention and mitigation of fire hazards. This innovative material is specifically designed to provide a robust barrier against fire, heat, and smoke, making it an indispensable tool for various industries.

- The black and yellow color combination is universally recognized as a warning signal, much like a wasp's distinctive stripes. In industrial settings, this tape is strategically placed to draw attention to areas that require special caution. For instance, it can mark out danger zones around heavy machinery or highlight slippery surfaces, ensuring that employees are aware of these hazards before they step into potentially risky areas.

The short answer is no, but the long answer is a bit more complicated.

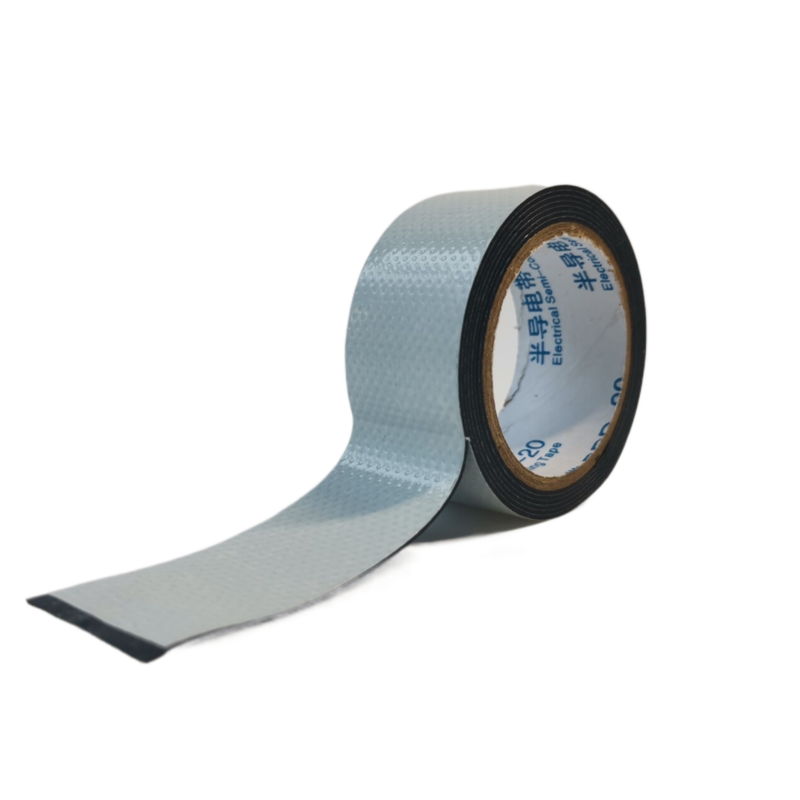

Polyethylene Rubber Tape has several important characteristics:

2. Stretch the tape Most amalgamating tapes come on a roll and need to be stretched before application. Gently stretch the tape to activate the adhesive properties.

The application process of Flex Tape is straightforward, adding to its appeal. To use, simply cut the desired length, peel off the backing, and press it firmly onto the surface needing repair. It’s advisable to clean the area to ensure maximum adhesion. Once applied, Flex Tape immediately begins to bond, and in most cases, further reinforcement is not necessary. This ease of use makes it accessible for individuals without extensive DIY experience while still appealing to seasoned professionals.

Another advantage of butyl rubber waterproofing is its environmental friendliness. The butyl rubber compound is non-toxic and VOC-free, making it safe for both the environment and the people applying it. It also has a long service life, reducing the need for frequent reapplications and minimizing waste. These eco-friendly characteristics make butyl rubber waterproofing a sustainable choice for waterproofing projects.

Another critical application of yellow electrical tape is for safety signaling. In environments where electrical work is ongoing, it is imperative to indicate areas that are off-limits or require caution. By wrapping yellow tape around specific zones or equipment, workers can alert others to potential hazards. This visual cue is crucial for minimizing accidents and injuries on the job site, which is a critical aspect of workplace safety protocols.

Engineered to beat the heat.

Another significant advantage of 3M HT Insulation Tape is its electrical insulation capabilities. The tape is constructed from high-quality materials that provide excellent dielectric strength, which is crucial in preventing electrical failures and ensuring the safe operation of equipment. This makes it an ideal choice for insulating wires, cables, and other electrical components in various applications. Whether used in motors, transformers, or circuit boards, 3M HT Insulation Tape helps to enhance performance and longevity while minimizing the risk of short circuits and other electrical hazards.

3m ht insulation tape

Using silicone self-adhesive tape is straightforward. Follow these steps to ensure a secure and effective repair:

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.

automotive fabric tape. This tape is engineered to withstand the wear and tear of daily use, making it a reliable long-term solution for any interior fabric repairs or upgrades. From resisting abrasions to repelling moisture and stains, automotive fabric tape is a resilient and long-lasting choice for automotive applications.Moreover, the environmental impact of PVC black tape has also come into consideration. While PVC products can be critiqued for their sustainability, many manufacturers are now focusing on creating eco-friendly options that minimize environmental harm. This shift signals a growing awareness within the industry about the importance of sustainability and responsible material usage.

(3) Even if it is wound around sharp complex shapes, it is still well sealed, waterproof, uniform and smooth, and can still maintain high insulation performance in high humidity environment;

One of the key characteristics of PVC tape is its durability. It is resistant to moisture, chemicals, and UV light, making it suitable for both indoor and outdoor applications. Additionally, it can withstand a wide range of temperatures, which is essential for environments where electrical systems may experience significant thermal fluctuations.

In addition to clear adhesive and magnetic tape, there are also specialized types of splicing tape designed for specific purposes

. For example, there is pressure-sensitive tape that is used in high-speed film editing machines to ensure quick and accurate splicing. There is also perforated tape that is used in conjunction with splicing equipment to create precise cuts in the film. black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness.

black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness.1. The surface needs to be clean and dry.Before applying the butyl sealant tape, it is essential to clean the surface where the tape will be applied. Remove any contaminants that can affect the adhesive properties of the tape. Gently scrub the surface with a soft cloth or sponge, and if necessary, utilize a mild cleaning solution. Once complete, make sure to let the area dry completely.