In conclusion, butyl rubber strip is a highly versatile and reliable material that offers exceptional resistance to heat, weather, chemicals, and adhesion properties. Its durability, flexibility, and long-term performance make it an ideal choice for a wide range of applications in different industries. Whether used for sealing, insulation, or protection purposes, butyl rubber strip provides a cost-effective solution that delivers reliable results in demanding environments.

- Yellow, often associated with caution, is a primary color used in safety markings. In the context of floor marking, yellow tape is predominantly used to indicate potential hazards or designated caution areas. It alerts individuals to be cautious when navigating through specific zones, such as machinery areas, fire exits, or areas with overhead hazards. The bright hue ensures that even from a distance, workers can easily identify these areas and take necessary precautions.

- 5. Easy Application The tape is easy to apply, requiring no special tools or equipment. It can be cut to size with scissors or a knife, making it a convenient choice for on-site applications.

In the construction business, there is always a need for versatile and reliable sealing materials. Butyl rubber sealant tape is a heavy-duty adhesive that provides exceptional flexibility, strength, and waterproofing capabilities. It is a powerful solution that is used to tackle various sealing and waterproofing applications, from sealing windows and RVs to patching rubber roofs on boats and repairing glass. In this article, we will explore the different facets of butyl rubber sealant, including its uses and installation.

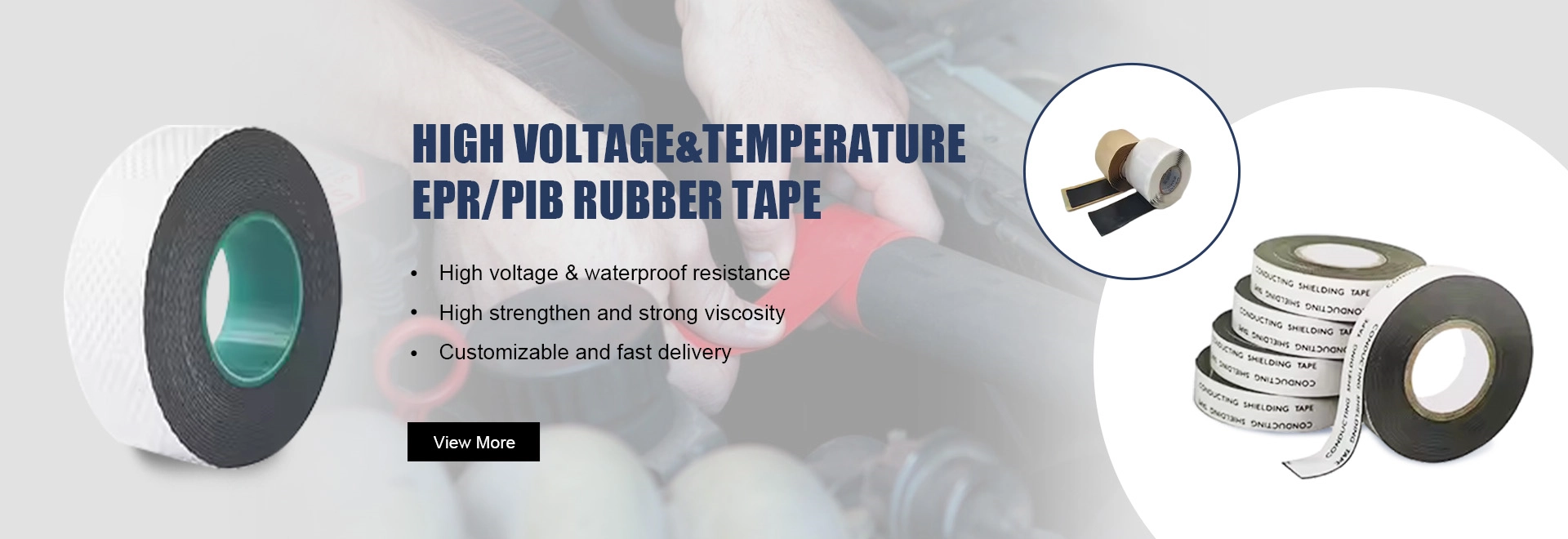

- 1. Electrical insulation High-voltage rubber tape is used to insulate wires, cables, and other electrical components to prevent electric shock and short circuits.

- One of the primary functions of PVC insulation electrical tape is to provide insulation to electrical conductors. It prevents the flow of electricity through unintended paths, reducing the risk of short circuits and electric shocks. The tape's dielectric strength, or its ability to resist the flow of electric current, is a key factor in its effectiveness as an insulator.

- 1. Material preparation PVC resin, plasticizers, stabilizers, and other additives are mixed together to create the tape's base material.

When you own a home with a well, problems can arise unexpectedly.

However, before we jump in, let’s establish a basic standard of what a control box is and what most people expect from a control box, as well as a quick review of the fundamentals of control box design. These topics will give you grounding in key concepts as you explore the best way to build and design your control box.

While price should not be the sole determining factor in selecting a supplier, it is still an important consideration. Compare pricing across different suppliers—but understand that lower prices may correlate with lower quality. Efficient distribution is another key factor. A supplier with a streamlined distribution network can ensure timely delivery, which is critical for project scheduling.

Repairing leaking pipes and pipe joints

cloth electrical tape. Its strong adhesive and durable nature make it ideal for fixing torn items, holding items together temporarily, or even for DIY projects. Its waterproofing capabilities further extend its usability to plumbing repairs or sealing packages.

cloth electrical tape. Its strong adhesive and durable nature make it ideal for fixing torn items, holding items together temporarily, or even for DIY projects. Its waterproofing capabilities further extend its usability to plumbing repairs or sealing packages.Protective plastic sheets and films can also be made of polyethylene. The surface protection tape that you find on new appliances is made of polyethylene film.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

Black Silicone Self-Fusing Sealing and Insulating Tape.

The main issue with buying tape online is that there are literally dozens of different types of adhesive tape on the market. Within each of these types, you can select from different options such as color, width, and thickness. The high degree of variation allows clients to select tapes that are perfectly tailored to their needs. However, some consumers can feel overwhelmed when reviewing their choices. Additionally, when you buy tape online, you have no way of knowing exactly how well the tape will work until your order arrives. Imagine buying a custom packing tape only to discover when it arrives that the width isn't compatible with your box sizes!

The rubber adhesive used in Polyethylene Rubber Tape offers several advantages that contribute to its performance and effectiveness.

3. Flexibility and Compressibility Butyl weather stripping is highly flexible, allowing it to conform to irregular surfaces and effectively fill gaps of varying sizes. It can compress under pressure yet return to its original shape, maintaining a consistent seal regardless of temperature changes.

varnish cambric tape. The tape can withstand temperatures of up to 155 degrees Celsius, making it a reliable choice for a wide range of applications.

Advantages of Butyl Weather Stripping

Width

Actuators simply receive and interpret your commands, which are delivered by the control interface thereby initiating mechanical action. Simply put, they alter the functioning of your connected devices as per the provided command. Your control box may come with either of the following actuators: