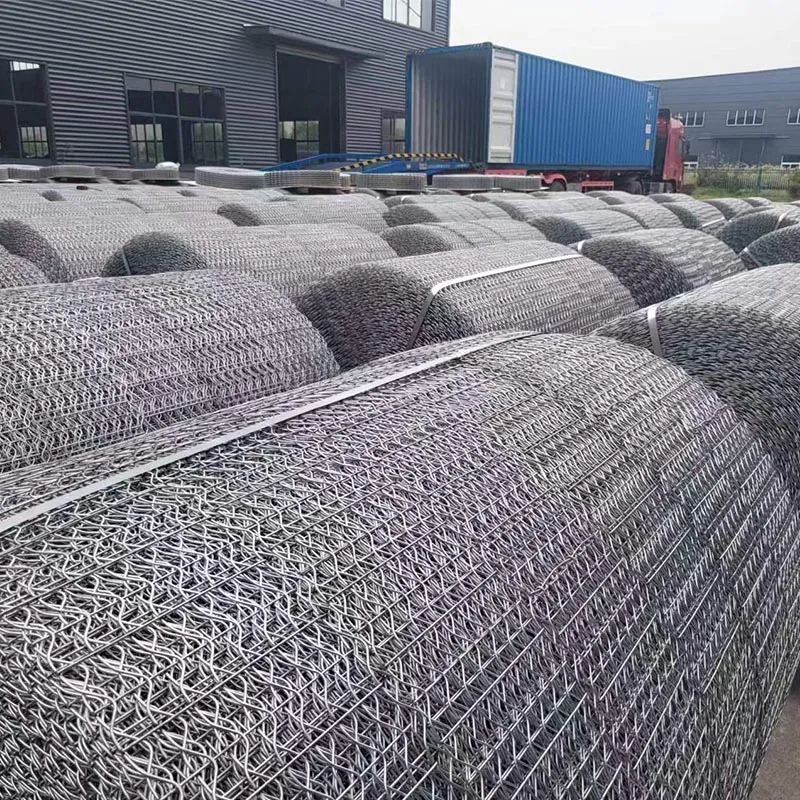

用途については、ガルバニizedスチールグレーチングは非常に多岐にわたります。工場の床やプラットフォーム、電気設備のカバー、階段、地下道の入口など、商業施設や公共施設で広く導入されています。また、交通機関のインフラ整備や公園の設計においても、その機能性から多く利用されています。特に、工業環境や建材の保管エリアでは、持続可能な選択肢として評価されています。

Kích thước Lưới Răng Cưa Một Khái Niệm Quan Trọng Trong Khoa Học Vật Liệu

1. Standard-Gitterroste Diese sind am weitesten verbreitet und werden oft in Industriebauten, Fußgängerwegen und als Abdeckungen für Gräben verwendet.

steel grating sizes

Types of Shale Shaker Screens

Moreover, serrated gratings can introduce unique diffraction patterns that are beneficial in laser applications. By customizing the shape and depth of the serrations, engineers can manipulate the angle and intensity of the emitted laser beams. This level of control opens new avenues in laser design, allowing for the creation of more efficient and focused laser systems. The resulting beams can be tailored for specific applications, whether in industrial machining, medical procedures, or communication systems.

serrated grating

Aluminium bar grating is a highly versatile material, widely used in various industrial and commercial applications due to its lightweight nature, durability, and excellent corrosion resistance. Composed of aluminium bars arranged in a grid pattern, this type of grating is popular in environments where both strength and low weight are critical considerations. With a growing emphasis on sustainable building practices and materials, aluminium grating offers an ideal solution for numerous structural and aesthetic needs.

Understanding Bar Steel Grating A Comprehensive Overview

Moreover, standard steel grating plays a crucial role in the oil and gas industry, where it is used in refineries and offshore platforms due to its ability to withstand harsh environmental conditions.

In conclusion, heavy steel grating stands out as a superior choice in construction and industrial settings. Its strength, durability, safety features, and low maintenance requirements make it an essential material for various applications. As industries continue to evolve, the demand for reliable, sustainable, and efficient building materials will undoubtedly keep heavy steel grating at the forefront of modern construction solutions. Whether you are planning a new project or looking to upgrade existing infrastructure, considering heavy steel grating can yield substantial long-term benefits.

3. Manufacturing Process The method used to manufacture the grating can also influence cost. Some processes, such as welded grating, may be more expensive than others due to the increased labor and materials involved. Customization, such as specific sizes or finishes, can also add to the final cost.

stainless steel bar grating price

Understanding Grating Hot Dip Galvanized Steel Benefits and Applications

Bar grating panels, also known simply as grating, are an essential component in a wide array of industrial, commercial, and architectural applications. These panels are made from various materials, including steel, aluminum, and fiberglass, and are characterized by their distinctive open design, which consists of a series of parallel bars and cross bars. This construction not only provides strength and durability but also allows for efficient drainage and ventilation, making them a versatile solution for many environments.

Edelstahl Gehwege Langlebigkeit und Ästhetik

One of the primary advantages of steel bar grating stair treads is their slip-resistant surface. The open design of the grating allows for excellent drainage, preventing the accumulation of water, ice, and debris. This feature makes them particularly valuable in areas prone to wet or slippery conditions, such as outdoor staircases and industrial settings. In addition, the surface of these treads can be enhanced with anti-slip coatings or textures, further increasing safety for users.

In addition to understanding the weight implications of bar grating, installers must also take into account the support structure needed for installation. The spacing of supports can affect how much load the grating can safely carry, and proper installation is vital to operational safety.