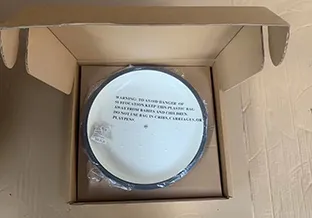

36cm wok

The non-stick properties of a well-seasoned cast iron skillet are another highlight. With proper care and seasoning, the skillet develops a natural non-stick surface that improves with use. This feature allows for easy release of food, minimizing the need for excessive oil or butter, which is especially beneficial for health-conscious cooks. Plus, cleanup remains simple; often, all that’s required is a quick wipe with a cloth or sponge.

Design and Features

Sartenes Artesanales a la Venta El Encanto de la Cocina Tradicional

The Restoration Process

rusty cast iron skillet

Non-cast iron Dutch ovens often come with a non-stick coating, which not only makes cooking and browning easier but also simplifies cleanup. For individuals and families with busy schedules, this feature is a game changer. There's no need to spend excessive time scrubbing away stuck-on food; a simple wipe with a damp cloth often suffices. Moreover, the non-stick surface allows you to use less oil or fat for cooking, making meals a bit healthier.

non cast iron dutch oven

Moreover, cast iron pots are environmentally friendly. With proper care, they can last a lifetime, reducing the need for disposable dishes. The durability and longevity of cast iron cookware align with a more sustainable approach to cooking, as it minimizes waste and encourages the use of quality products.

Retail stores and online marketplaces may offer different prices for the same seal, depending on factors such as competition, overhead costs, and shipping fees Retail stores and online marketplaces may offer different prices for the same seal, depending on factors such as competition, overhead costs, and shipping fees

Retail stores and online marketplaces may offer different prices for the same seal, depending on factors such as competition, overhead costs, and shipping fees Retail stores and online marketplaces may offer different prices for the same seal, depending on factors such as competition, overhead costs, and shipping fees