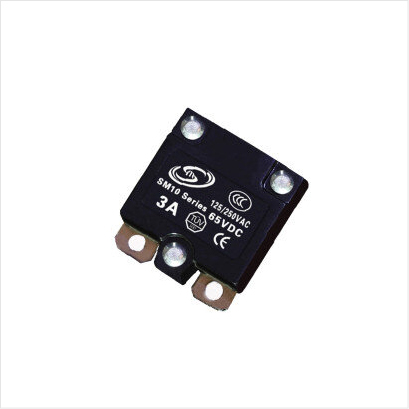

Actuators simply receive and interpret your commands, which are delivered by the control interface thereby initiating mechanical action. Simply put, they alter the functioning of your connected devices as per the provided command. Your control box may come with either of the following actuators:

flex tape black 4 in x 5 ft. Press down firmly to ensure a secure bond, and your repair is complete. There is no need for messy adhesives, complicated tools, or drying time – Flex Tape Black provides a quick and reliable solution to your repair needs.

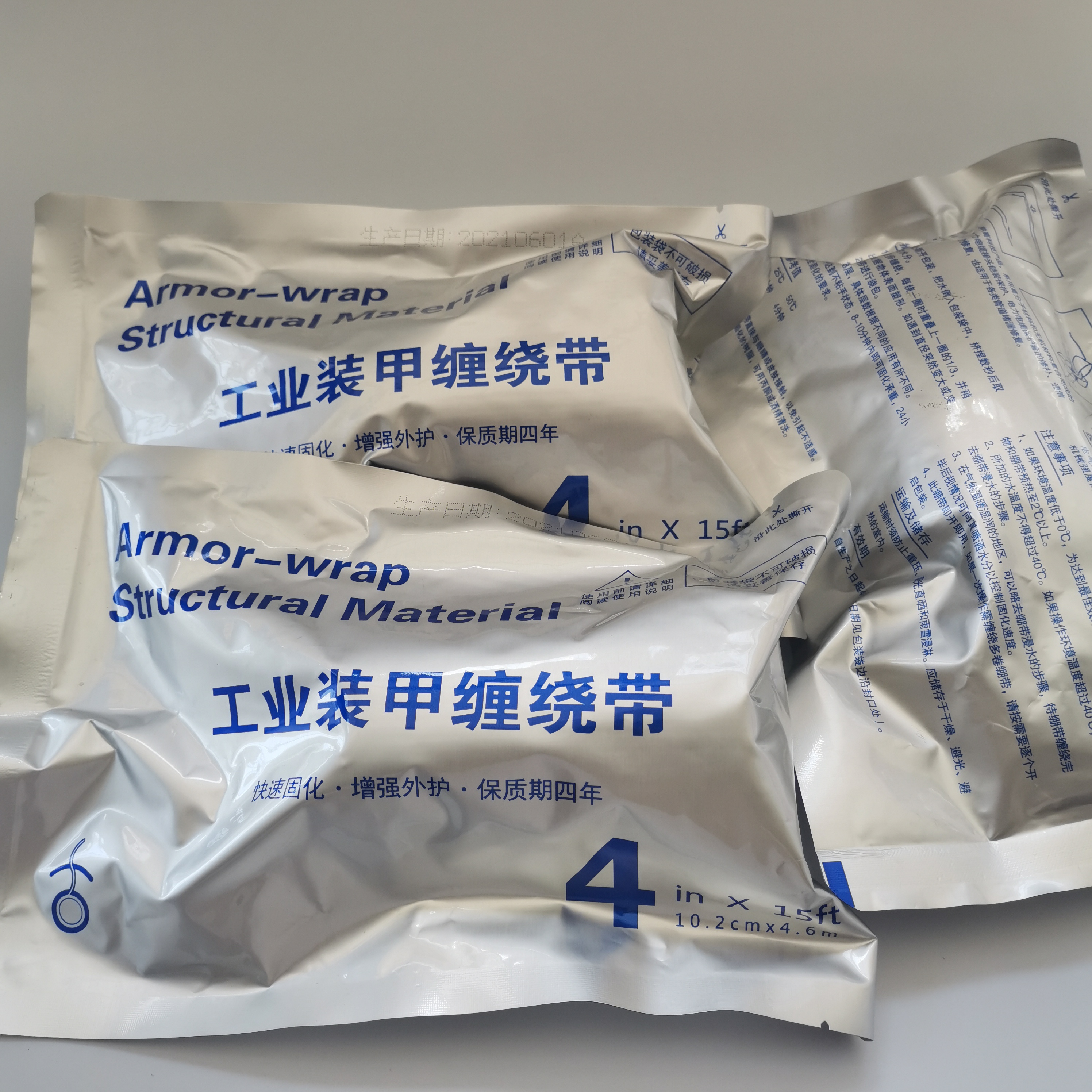

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.

1. Inspect the Area Check for any gaps around doors and windows. A simple test is to close a door or window and see if light passes through; if it does, weather stripping is needed.

The Versatility and Significance of PVC Electrical Insulation Tape in Wholesale Markets

Is silicone tape the same as silicone sheets?

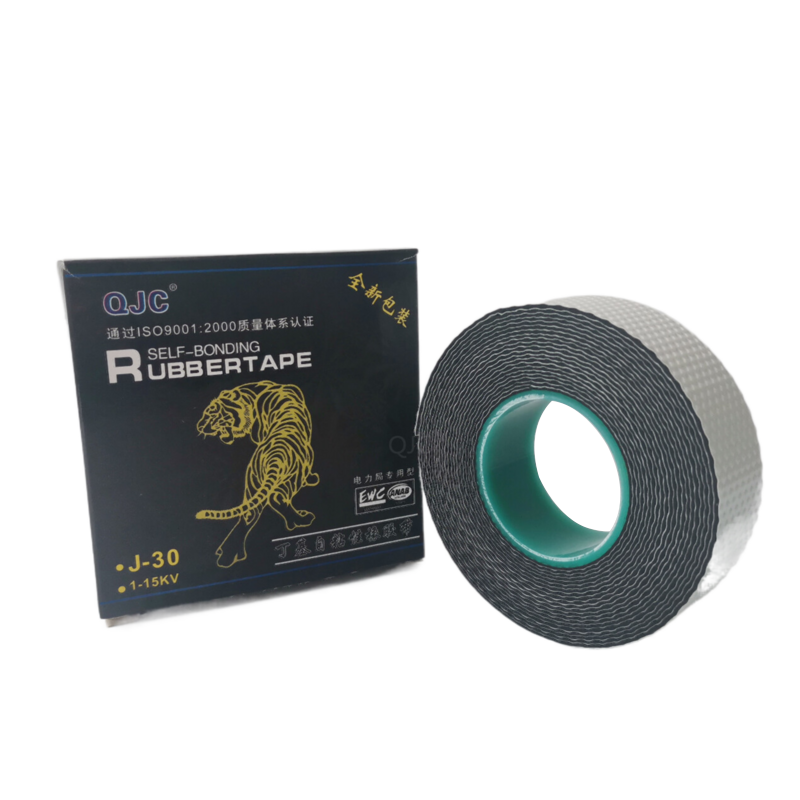

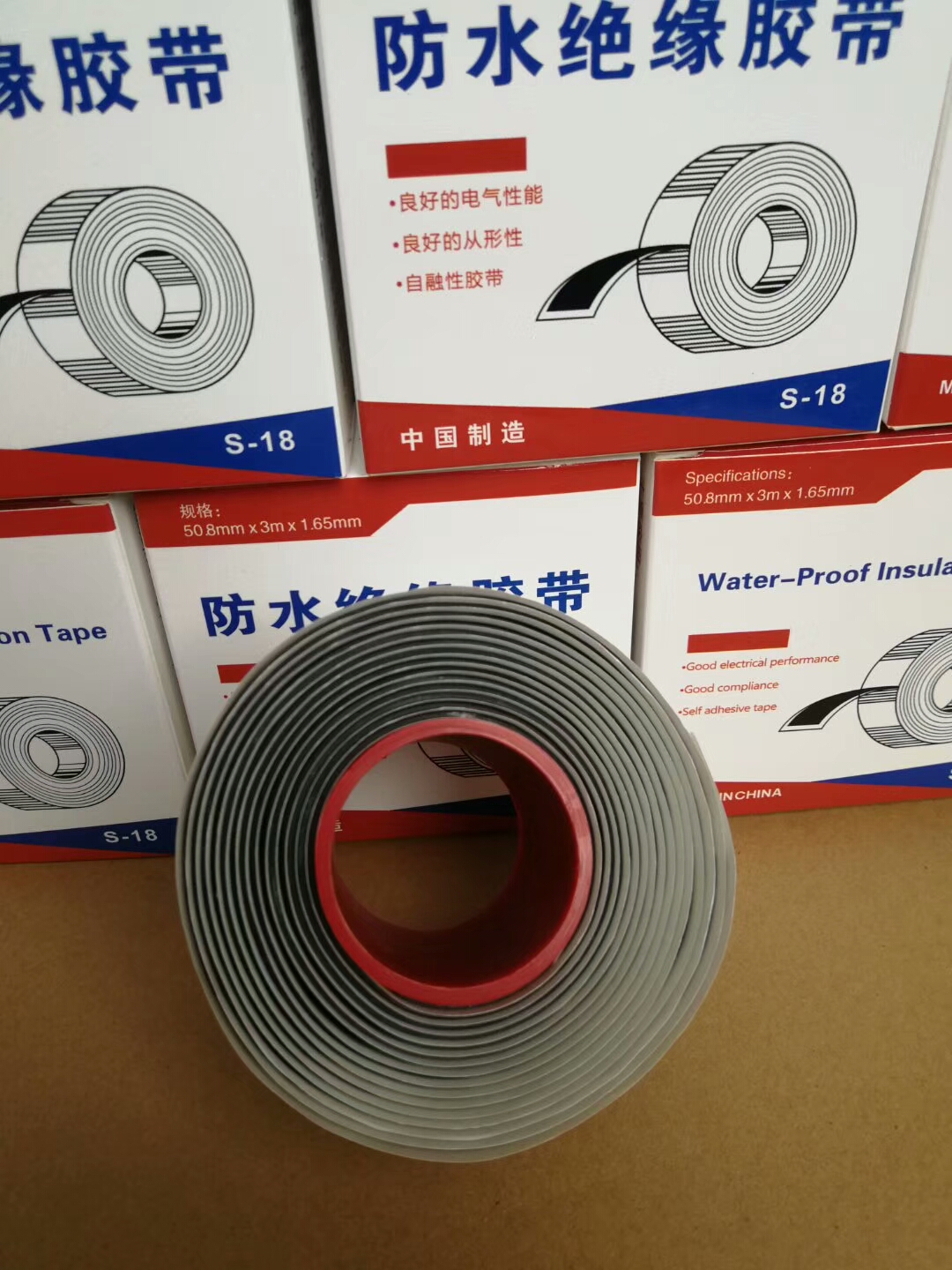

grey pvc tape. The tape's resistance to oils and chemicals makes it suitable for use in engine compartments and other areas where exposure to harsh substances is common.

In residential settings, homeowners can use fire-resistant electrical tape for DIY electrical repairs. For instance, if they encounter frayed wires or damaged insulation, using a fire-resistant tape can help restore the integrity of the electrical system while minimizing fire risks. It's a practical solution for ensuring safety without the need for extensive rewiring.