- Redispersible powder polymers have revolutionized various industries with their unique ability to form a uniform, cohesive film when mixed with water. These specialized powders offer unparalleled convenience and performance, making them an essential component in modern construction materials, adhesives, and paints.

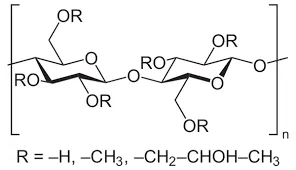

- The first step in the factory process is the alkalization stage. The raw cellulose is mixed with strong alkali, such as sodium hydroxide, under controlled conditions. This treatment breaks down the hydrogen bonds within the cellulose, making it more accessible for further reactions. The alkali concentration, temperature, and reaction time are critical parameters that influence the final properties of HPMC.

- Another important application of HPMC is as a stabilizer in emulsions and suspensions. HPMC can prevent particles from settling out of a solution, ensuring uniformity and stability over time. This is crucial in industries such as the food and beverage industry, where emulsions and suspensions are commonly used in products such as salad dressings, sauces, and beverages.

- This unique powder, derived from vinyl acetate-ethylene (VAE) copolymer, is primarily used for its water-resistant, bonding, and plasticizing characteristics. It finds extensive use in tile adhesives, repair mortars, and external thermal insulation composite systems (ETICS). In recent years, China's production and export of redispersible powder have significantly contributed to the industry's growth.

- HPMC is a derivative of cellulose and is commonly used as a thickener, binder, and film-former. It is also known for its excellent water retention and adhesion properties, making it an ideal ingredient in many formulations. The different grades of HPMC are categorized based on their viscosity, with higher viscosity grades being more thickening and lower viscosity grades being more dispersible.

- ,HPMC。,。,HPMC,。

- To make HPMC, cellulose undergoes a series of chemical modifications. The first step involves treating cellulose with alkali to create alkali cellulose. This is then reacted with propylene oxide to introduce hydroxypropyl groups onto the cellulose chain. Finally, methyl chloride is added to replace hydrogen atoms with methyl groups, resulting in the formation of HPMC.

hpmc polymer. It improves the texture and consistency of food products while maintaining their stability over time. Its vegan-friendly nature makes it a popular alternative to animal-based ingredients.

hpmc polymer. It improves the texture and consistency of food products while maintaining their stability over time. Its vegan-friendly nature makes it a popular alternative to animal-based ingredients.

HPMC is commonly found in food products, acting as a stabilizer and emulsifier HPMC is commonly found in food products, acting as a stabilizer and emulsifier

HPMC is commonly found in food products, acting as a stabilizer and emulsifier HPMC is commonly found in food products, acting as a stabilizer and emulsifier hec vs hpmc. In the pharmaceutical sector, it is extensively used as a controlled-release excipient in tablet formulations and as an eye drop viscosifier.

hec vs hpmc. In the pharmaceutical sector, it is extensively used as a controlled-release excipient in tablet formulations and as an eye drop viscosifier.Dispersive ophthalmic viscosurgical device (OVD) used to create and maintain anterior chamber depth and visibility, as well as to protect intraocular tissues during surgery.

It is predominantly used in the production of wall putty, plasters, and tile adhesives It is predominantly used in the production of wall putty, plasters, and tile adhesives

It is predominantly used in the production of wall putty, plasters, and tile adhesives It is predominantly used in the production of wall putty, plasters, and tile adhesives hpmc types. Its ability to improve the cohesive strength and open time of these products is highly valued.

hpmc types. Its ability to improve the cohesive strength and open time of these products is highly valued.If you’re looking for cellulose ethers as a functional additive in your dry mortar mixes, you may be wondering about the differences between hydroxypropyl methyl cellulose (HPMC) and methyl cellulose (MC). Both HPMC and MC are cellulose-based polymers derived from plant cellulose. They’re non-toxic, biodegradable and non-carcinogenic. So what’s the difference between them? In this article, we’ll explore the key differences between HPMC and MC and help you decide which one is right for your needs.

Conclusion

HPMC is used as a thickening, stabilizing, and gelling agent in a wide range of products, such as sauces, dressings, soups, dairy products, desserts, and beverages.

These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics

These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics what is hpmc made from.

what is hpmc made from. This is particularly useful for repairing and restoring damaged structures, as it allows for the effective bonding of new materials to existing substrates This is particularly useful for repairing and restoring damaged structures, as it allows for the effective bonding of new materials to existing substrates

This is particularly useful for repairing and restoring damaged structures, as it allows for the effective bonding of new materials to existing substrates This is particularly useful for repairing and restoring damaged structures, as it allows for the effective bonding of new materials to existing substrates latex bonding agent.

latex bonding agent.