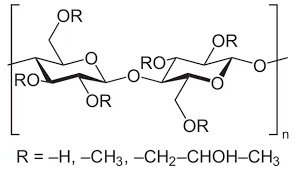

HPMC is a semi-synthetic polymer derived from cellulose, characterized by its hydroxypropyl and methyl substitutions. This modification allows HPMC to exhibit unique properties, such as improved water solubility, viscosity, and adhesion. Due to these properties, HPMC is employed as a thickening agent, emulsifier, and film-forming agent in various formulations.

5. Flexible Setting Times HPMC allows for flexibility in setting times, which can be adjusted according to the project requirements. This adaptability is especially beneficial for large tiling jobs or in varying environmental conditions.

Is HPMC Water Soluble? An In-Depth Look at Hydroxypropyl Methylcellulose

Redispersible polymer powder (RDP) plays a significant role in various construction and adhesive applications, known for enhancing the flexibility, adhesion, and durability of mixtures. The manufacturing process of RDP involves several crucial steps that ensure the final product meets the desired performance standards.

Hydroxypropyl MethylCellulose has many features such as thickening power, salt discharge performance, pH stability, water retention, excellent film-forming properties, extensive resistance to enzymes, dispersion and adhesion.

In the pharmaceutical sector, HPMC is paramount due to its role as a controlled drug release agent. It is often used in the formulation of tablets and capsules, enhancing bioavailability and ensuring a sustained release of active ingredients. Moreover, its solubility in cold water makes it an ideal binder and lubricant in tablet production.

2. Specialized Chemical Suppliers Many chemical supply companies specialize in selling various grades of hydroxyethyl cellulose. Companies like Sigma-Aldrich, Fisher Scientific, or local suppliers might have dedicated sections for HEC. This option often provides you with more detailed product information, including specifications and handling guidelines.

1. Online Retailers

Understanding Hydroxypropyl Methylcellulose A Multifaceted Polymer

Hydroxypropyl methyl cellulose ether is a multifaceted polymer that plays a significant role across diverse industries. Its unique properties, such as solubility in cold water, thickening ability, and biocompatibility, make it an essential ingredient in pharmaceuticals, food, cosmetics, and construction. As the demand for sustainable and versatile additives continues to grow, HPMC will likely maintain its crucial position in these industries, further exemplifying the benefits of natural-derived compounds in modern applications.

Manufacturers invest in research and development to innovate and enhance the properties of HEC. This continuous improvement not only elevates the quality of the product but also expands its range of applications.

Impact on Personal Care Products

Solubility Characteristics

In conclusion, the thickening mechanism of hydroxyethyl cellulose is a complex interplay of hydration, molecular interactions, and external conditions. Its ability to form viscous gels through water interaction, influenced by concentration and various factors, underlines its importance across multiple industries. As ongoing research continues to explore its properties, HEC will likely remain a fundamental ingredient for achieving desired thickness and stability in numerous formulations.

Properties of Hydroxyethyl Cellulose

hpmc-hydroxypropyl methyl cellulose manufacturer.

Hydroxypropyl Methylcellulose (HPMC) has become an essential ingredient in the formulation of tile adhesives, playing a critical role in enhancing the performance and application of these materials. As a non-ionic cellulose ether derived from natural plant sources, HPMC is widely recognized for its versatile properties, making it an invaluable component in the construction industry.

HPMC is created by the chemical modification of cellulose through the substitution of hydroxyl groups with hydroxypropyl and methoxy groups. This modification provides HPMC with its unique properties, including solubility in water and a range of viscosities. Depending on the degree of substitution and the molecular weight, HPMC can form clear, viscous solutions or solid gels. Its ability to dissolve in both hot and cold water makes it particularly valuable in a variety of applications.

HPMC grades are categorized based on their viscosity, typically measured in centipoise (cP) at a specific concentration and temperature. Common grades include

hpmc grades viscosity

1. Quality Control Top manufacturers adhere to strict quality control protocols and regulatory standards to ensure their HPMC meets the required specifications and is safe for use in various applications.

2. Temperature Temperature can dramatically affect the viscosity of HEC solutions. As temperature increases, viscosity typically decreases. This is attributed to the increased molecular motion that allows polymer chains to move more freely, thus reducing resistance. In practical applications, formulators must consider these temperature-related changes, especially in manufacturing and application environments.

- Enhanced Adhesion and Flexibility The addition of VAE improves the product’s ability to bond with various surfaces, ensuring a long-lasting application that resists peeling and cracking, even under stress.

Food grade HPMC is another commonly used grade of HPMC. In the food industry, HPMC is employed as a thickener, stabilizer, emulsifier, and texture modifier in a wide range of food products, including sauces, dressings, desserts, and meat products. It is also used in gluten-free baking as a substitute for gluten to improve the texture and shelf-life of baked goods. Food grade HPMC is generally recognized as safe by regulatory authorities and is widely accepted as a food additive in many countries around the world.

The HPMC Manufacturing Process

HPMC is a versatile and safe polymer that plays a critical role in various industries. Its wide-ranging applications—from pharmaceuticals to food and cosmetics—underscore its importance in modern formulations. As research continues to explore new applications for HPMC, understanding its safety profile remains essential for manufacturers, formulators, and consumers alike. By adhering to established guidelines and recommended usage levels, stakeholders can harness the benefits of HPMC while ensuring safety and efficacy in their products. Consequently, HPMC stands out as a dependable material, promoting innovations across diverse sectors while prioritizing consumer safety.

The Chemical Modification Process

propyl methyl cellulose.

3. Thickening Agents In liquid formulations, HPMC acts as a thickening agent, improving the product's stability and consistency. This is particularly important in formulations such as syrups and suspensions.

Redispersible polymer powder (RDP) is a versatile additive utilized in various construction and manufacturing processes. As a key component in many formulations, RDP significantly enhances the properties of end products, making it essential in modern materials science. This article delves into what RDP is, its applications, and the benefits it offers across different industries.

what is hydroxyethyl cellulose used for. It also helps to reduce shrinkage and cracking during the curing process, resulting in a more durable and long-lasting finish.

Pharmaceutical applications of HEC are equally noteworthy; it serves as a controlled-release agent in the formulation of tablets and ointments. Its ability to form a viscous gel when hydrated aids in the sustained release of active ingredients, thereby improving therapeutic efficacy.

1. Online Marketplaces

The manufacturing process of HPMC is complex, requiring precise control over the chemical modification and purification stages to ensure high quality and bioavailability of the final product. HPMC manufacturers must adhere to stringent regulatory standards, such as Good Manufacturing Practices (GMP) and ICH guidelines, to guarantee that their products meet the safety and efficacy requirements of the pharmaceutical industry.

HPMC

3. Food Industry In food applications, HPMC acts as a thickening agent and emulsifier, often enhancing textural properties in products like sauces, dressings, and gluten-free baked goods.

1. Molecular Weight HPMC grades with lower molecular weights dissolve more readily in water. High molecular weight grades may require heating or longer mixing times to achieve complete dissolution.

4. Regulatory Environment HPMC's use in the food and pharmaceutical industries is subject to stringent regulations concerning safety and quality. Compliance with these regulations often requires additional testing and certification processes, which can add to production costs. Changes in regulatory policies can thus impact HPMC pricing patterns.

hydroxypropyl methylcellulose price

Hydroxypropyl methylcellulose (HPMC) is a versatile, semi-synthetic polymer derived from cellulose, widely used in various industries due to its beneficial properties. As a non-ionic cellulose ether, HPMC exhibits multiple characteristics that make it a preferred choice in applications ranging from pharmaceuticals to construction. Understanding the properties of HPMC is crucial for optimizing its usage in different fields.

The cosmetic and personal care industry also benefits from the versatile properties of MHEC. It is commonly used in formulations such as shampoos, conditioners, lotions, and creams. MHEC contributes to the thickening and stabilization of these products, enhancing the overall user experience. Additionally, its moisturizing properties make it an attractive ingredient in skin and hair care products, offering consumers longer-lasting hydration and improved texture.

What is HPMC?

Macromolecules: from about 13,000 (n about 70) up to about 200,000 (n about 1000)

These gels can also stabilize emulsions, preventing the separation of oil and water phases in products such as moisturizers and sunscreens. Furthermore, due to its non-toxic nature and low irritancy, HPMC is a preferred ingredient in products designed for sensitive skin types.

Hydroxypropyl methylcellulose (HPMC) is a cellulose-derived compound that has garnered significant attention across various industries due to its versatile properties. As a non-ionic, water-soluble polymer, HPMC is widely used as a thickening agent, film-forming agent, and stabilizer in numerous applications, including pharmaceuticals, food products, and construction materials.

Applications of HPMC in Construction