The versatility of overlockers allows them to handle a wide range of fabrics, from lightweight knits to heavy denim. This adaptability is particularly important as fashion trends shift and materials evolve. With the rise of stretchy, knit fabrics in fashion, overlockers have become increasingly important in ensuring the comfort and durability of garments.

- The key features that set an industrial sewing machine apart for auto upholstery include their strong motor, which allows them to sew through multiple layers of material effortlessly. They often come with a variety of presser feet, each tailored for specific tasks like sewing seat cushions, door panels, or headliners. The adjustable stitch length and width provide versatility, while the heavy-duty feed dogs ensure smooth fabric movement under the needle.

In conclusion, the industrial bag closing machine head is an essential component of modern manufacturing and packaging processes. With its ability to enhance efficiency, provide consistent sealing, offer versatility across different bag types, reduce waste, and ensure user-friendly operation, it represents an investment in quality and reliability. As industries continue to evolve and demand greater productivity, the importance of these machine heads will only grow, making them integral to the success of packaging operations worldwide. By integrating high-quality industrial bag closing machine heads into their production lines, manufacturers can not only improve their operational efficiency but also enhance the overall quality of their products, ultimately leading to customer satisfaction and business growth.

In conclusion, the overlock chain stitch is a remarkable stitch that offers both functionality and aesthetic appeal. By understanding its characteristics and benefits, sewists can enhance their skills and produce high-quality garments and projects. Whether for professional use or personal creative endeavors, mastering the overlock chain stitch opens up a world of possibilities in the art of sewing. Embracing this stitch not only transforms how we sew but also elevates the final product, ensuring durability, style, and satisfaction in every project.

As technology continues to advance, the double stitch machine is evolving alongside it. Modern machines are now equipped with computerized controls that allow for precise stitch length adjustments, automatic thread tension regulation, and even intricate embroidery capabilities. This technological integration not only enhances the quality of the final product but also provides manufacturers with greater control over the production process.

Needle feed sewing machines are widely used across different sectors of the textile industry. In the garment manufacturing sector, they are essential for sewing complex patterns, fortifying seams, and working with layered fabrics. This capability makes them particularly valuable for producing high-quality clothing items, including suits, dresses, and outerwear.

double foot sewing machine. By feeding fabric through the machine evenly from both sides, this type of sewing machine produces consistent and reliable results, even when working with challenging materials.

Conclusion

2. Juki TL-2010Q Known for its exceptional precision and speed, the Juki TL-2010Q features a walking foot and a heavy-duty frame. It is perfect for quilters and leatherworkers alike, making it a versatile choice for anyone interested in pursuing various sewing projects.

In conclusion, handheld leather sewing machines serve as an excellent addition to the toolkit of any leatherworking enthusiast. Their portability, user-friendly design, versatility in handling various leather types, and ease of maintenance make them accessible and practical for users at all skill levels. Whether you're a hobbyist exploring the world of leathercraft or a seasoned artisan seeking to expand your repertoire, investing in a handheld sewing machine can unlock new possibilities and enhance your creative journey. With the right tools in hand, the only limit is your imagination.

single needle sewing. Whether you are working with delicate silk or thick canvas, single needle sewing can be adapted to suit the needs of your project. This flexibility makes it a popular choice among sewers of all skill levels.

single needle sewing. Whether you are working with delicate silk or thick canvas, single needle sewing can be adapted to suit the needs of your project. This flexibility makes it a popular choice among sewers of all skill levels.Plastic bag closer machines are indispensable assets in the modern manufacturing landscape. Their ability to enhance efficiency, ensure product quality, and adapt to changing market demands positions them as vital components for businesses looking to thrive in a competitive environment. As technology continues to advance, so too will the capabilities and functionalities of these machines, proving that they are not just a temporary solution but a cornerstone of efficient packaging processes for years to come.

In addition to its spacious workspace, long arm stitching machines also offer greater visibility and control. The extended arm allows you to see more of your project as you work, making it easier to ensure accurate stitching and precise details. This increased visibility also means less strain on your eyes and neck, providing a more comfortable sewing experience.

Conclusion

One of the most critical features to look for in a sewing machine for both fabric and leather is stitch control. The ability to adjust the stitch length and type is vital when switching between materials. For instance, when sewing leather, a longer stitch length (usually between 3-5mm) helps reduce the chances of puncturing the material too many times, which can lead to tearing. In contrast, for lightweight fabrics, a shorter stitch length provides greater control and a more refined finish.

sewing machine for fabric and leather

In conclusion, twin needle sewing is a valuable technique that serves multiple purposes in the sewing world. From creating stretchy hems in knit fabrics to adding decorative details and enhancing the durability of seams, this method is an essential tool for anyone looking to refine their sewing skills. Whether you're a beginner or an experienced sewist, mastering twin needle sewing can open new doors for creativity and precision in your sewing projects. By utilizing this technique, you can achieve professional-looking results that showcase your craftsmanship and elevate your handmade creations.

To effectively use a manual leather stitching machine, artisans must grasp a few key techniques. First, the selection of the right thread and needle is crucial. Leather thread, typically made from synthetic materials or waxed cotton, is preferred for its strength and durability. The needle should be specific to leather, with a sharp point that can penetrate the tough material without causing excessive damage.

manual leather stitching machine

Sewing machine specials are often rolled out during various sales events throughout the year—think Black Friday, Cyber Monday, or even seasonal sales. These promotions can include discounts on specific brands or models, bundled accessories, or even financing options that make purchasing a new machine more accessible. For many, these specials can be a golden opportunity to invest in a higher-end machine that might have otherwise been out of reach.

The Pricing Landscape of Auto Sewing Machines

Moreover, the environmental impact of using hi-speed lockstitch machines is a consideration that is gaining importance in the textile industry. With rising awareness about sustainability, manufacturers are keen on adopting technologies that reduce waste and energy consumption. The efficiency and precision of hi-speed lockstitch machines contribute to minimizing fabric scrap during production, aligning with eco-conscious practices.

Twin needle sewing is also an excellent method for creating pintucks—a technique that involves sewing narrow, raised seams that add texture and visual interest to fabric. Using a twin needle allows sewists to produce multiple pintucks at one time, significantly reducing the stitching effort and time required. This technique is often employed in blouses and skirts, offering an elegant finish that elevates the overall design.

Heavy-Duty Sewing Machines: These machines, designed for domestic use, often have user-friendly features. They might have digital displays, easy threading capabilities, and straightforward stitch selection processes.

The Importance of Upholstery Stitching Machines in Modern Manufacturing

One of the defining features of heavy-duty sewing machines is their robust construction. Unlike standard sewing machines, which may falter under the strain of thick fabrics, heavy-duty machines are built with stronger frames and powerful motors. This allows them to easily sew through multiple layers of fabric, leather, denim, and heavy canvas. Such resilience is particularly beneficial for those who work with tough materials on a regular basis. For instance, upholstery professionals often rely on these machines to create stylish yet hardy furniture covers, while outdoor enthusiasts may use them to make camping gear designed to withstand the elements.

In the ever-evolving world of sewing, the long arm zig zag sewing machine stands out as a revolutionary tool for both hobbyists and professional seamstresses alike. This versatile machine combines the features of long arm sewing with the capabilities of zig zag stitching, making it an essential ally for those who take their sewing projects seriously.

In the world of textiles and fashion, sewing machines have long been an essential tool for both hobbyists and professionals. Among the various types of sewing machines available today, the computerized sewing machine stands out for its advanced features and capabilities. But what exactly does a computerized sewing machine do, and how does it enhance the sewing experience?

Moreover, these machines often come with advanced features such as adjustable stitch width and length, which provides even more customization. Some models include built-in memory functions that allow users to save their preferred settings, making it easy to reproduce specific looks in future projects. This technology not only enhances the user experience but also promotes a professional finish, crucial for those seeking to sell their creations.

2. Use the Right Tools Invest in high-quality needles and thread suitable for the fabric being used. The right tools make a significant difference in the outcome and efficiency of the work.

Furthermore, the consistency of the stitching produced by this machine reduces the need for alterations and repairs, which can savings on labor and material costs. The high-quality finish that double needle stitching provides often results in garments that require fewer touch-ups, enhancing overall productivity.

I was obsessed: The Singer “Heavy Duty” Sewing Machine, which can be found refurbished for as low as $160, was proving difficult to find, thanks to the quarantine crafting boom, and I refused to settle for anything less.

Benefits of Using an Upholstery Sewing Table

One of the primary advantages of bag closing sewing machine heads is their ability to enhance productivity. With automation, these machines can close hundreds of bags in a matter of minutes, far surpassing manual methods. This not only speeds up the workflow but also minimizes labor costs, allowing companies to allocate resources more efficiently.

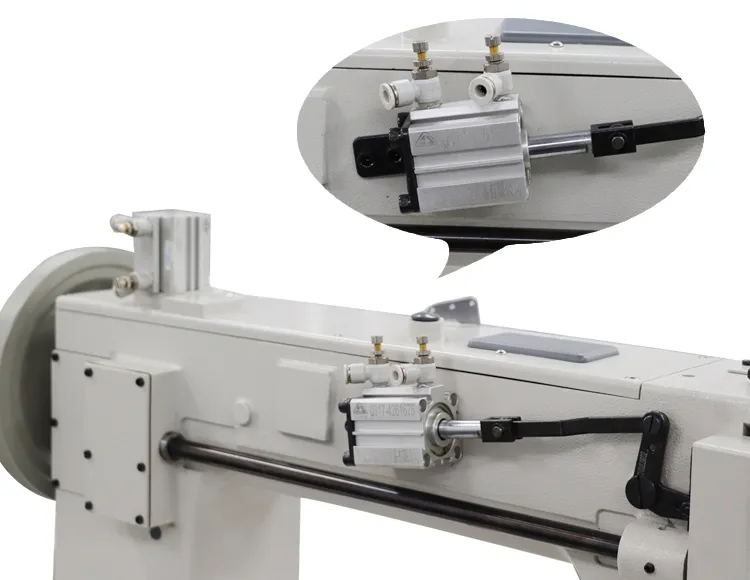

bag closing sewing machine head

In conclusion, chain stitch sewing machines are a testament to the evolution of textile technology. Their ability to produce durable, flexible, and aesthetically pleasing seams makes them indispensable in various sectors of the sewing industry. As sustainability becomes a paramount concern, the practicality of chain stitch sewing will likely see a resurgence, affirming this machine's place in the future of fashion and textile production. Whether in a bustling factory or a home sewing setup, the chain stitch sewing machine will continue to inspire creativity and innovation for years to come.

1. Select the Right Double Needle Choose a double needle that suits your project. The needle size (e.g., 80/12 or 90/14) and the distance between the needle points will affect your stitching. A 2-3mm spacing is standard for most uses.

Several brands are well-regarded in the world of heavy-duty sewing. Machines like the Sailrite Fabricator, Juki TL2010Q, and Brother PQ1500SL are often recommended for upholstery due to their strength and functionality. Each of these models offers various features that make them suitable for sewing through multiple layers of tough fabrics.

Another user-friendly aspect is the variety of built-in stitches that these machines often offer. Heavy-duty sewing machines typically include a selection of stitches that can accommodate different sewing styles and techniques, from straight and zigzag stitches to buttonholes and decorative patterns. This versatility encourages creativity and makes it easier for users to experiment with different designs. Switching between stitches is usually straightforward, often accomplished with the simple turn of a dial or the press of a button.

easy to use heavy duty sewing machine