- However, it's important to note that while PVC electrical tape is highly effective, it may not be suitable for high-voltage applications or situations requiring extreme heat resistance. For such cases, specialized tapes like silicone or vinyl-nitrile may be more appropriate.

- Inside of an industrial control panel, it is absolutely necessary to accurately identify all of the wires, ports, and other equipment. Using this method saves time and decreases the risk of making mistakes during testing, routine maintenance, and repairs.

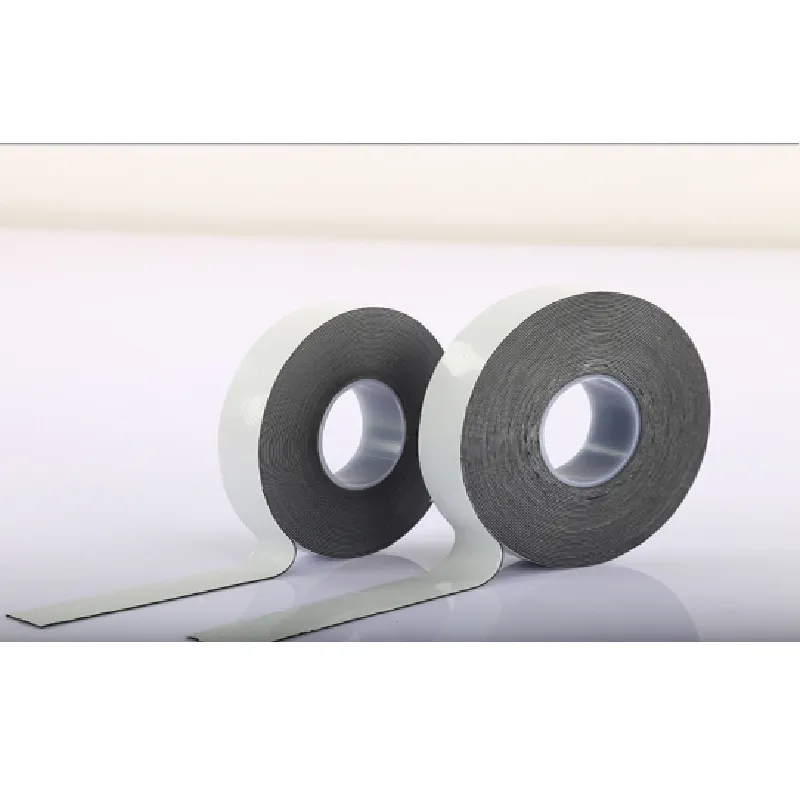

- Rubber

Each of these adhesive types have advantages and disadvantages which make them more or less suitable for particular applications. Here we will draw the major lines outlining these differences.

super strong waterproof flex tape. Its flexibility also means it can be used in a variety of creative ways. Crafters use it for sturdy hinges on DIY projects, while athletes have been known to use it as a temporary fix for torn equipment. Gardeners love it for reinforcing plant ties, and it's a lifesaver for quick, emergency repairs on everything from camping gear to household items.

super strong waterproof flex tape. Its flexibility also means it can be used in a variety of creative ways. Crafters use it for sturdy hinges on DIY projects, while athletes have been known to use it as a temporary fix for torn equipment. Gardeners love it for reinforcing plant ties, and it's a lifesaver for quick, emergency repairs on everything from camping gear to household items.How to apply self-amalgamating tape

We’ll also provide some tips on how to choose the right type of tape for your needs!

1. Leak Repairs Flex Tape can be a lifesaver for plumbing issues. A small break or leak in a pipe can lead to extensive water damage, but with Flex Tape, you can quickly seal the hole until a more permanent solution is found.

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.

Conclusion

The Difference Between Silicone Rubber Tape and Rubber Repair Tape

The well pumps that provide water to private well systems are another area in which you’ll frequently find control boxes. Typically, these designs are relatively simple—but, like all control boxes, they serve a critically important purpose.

Why Would You Use A Self-Fusing Tape Instead of a Adhesive Tape?

Polyethylene Tape, or PE Tape, is a type of adhesive tape made from polyethylene, a durable and versatile thermoplastic polymer. It finds a wide range of applications due to its various properties and benefits.