However, it's worth noting that the maintenance of wrought iron railings requires some effort. Regular cleaning, painting, or rust-proofing treatments are necessary to keep them in optimal condition. Despite this, the enduring beauty and durability they provide make the upkeep worthwhile.

Before you build your next shed, consider whether it would be better to build with an aluminium frame profile or not. It is one of the biggest choices that you will have to make and you have to make sure that you are choosing the right type of material to suit your needs and budget. This is because there are many materials available on today's market but none of them give you the flexibility that aluminium frame profile offers. If you are unsure as to whether this is the right option for your shed then why not have a look online. You may even find that it will be better for you to go down this route than any other.

One obvious component that cannot be overlooked is the metal fence posts. These make up an important part of the structure of your pool fence. You will also need to think about the iron safety fence panels, the wrought iron pool gate that allows for easy entry and exit to and from the pool, as well as other small parts like caps, bushings, and so on. If you are not going to install the pool fence yourself, you won’t need to have such a detailed grasp on the way these items are constructed. However, it is still a good idea to have a basic understanding of the product so you can watch for problems and check the quality of the work after it has been completed.

Thanks to advanced manufacturing techniques, aluminium frames can now incorporate thermal breaks, which prevent heat transfer from the interior to the exterior Thanks to advanced manufacturing techniques, aluminium frames can now incorporate thermal breaks, which prevent heat transfer from the interior to the exterior

Thanks to advanced manufacturing techniques, aluminium frames can now incorporate thermal breaks, which prevent heat transfer from the interior to the exterior Thanks to advanced manufacturing techniques, aluminium frames can now incorporate thermal breaks, which prevent heat transfer from the interior to the exterior aluminium window frame section. This not only enhances energy efficiency but also contributes to a more comfortable indoor environment.

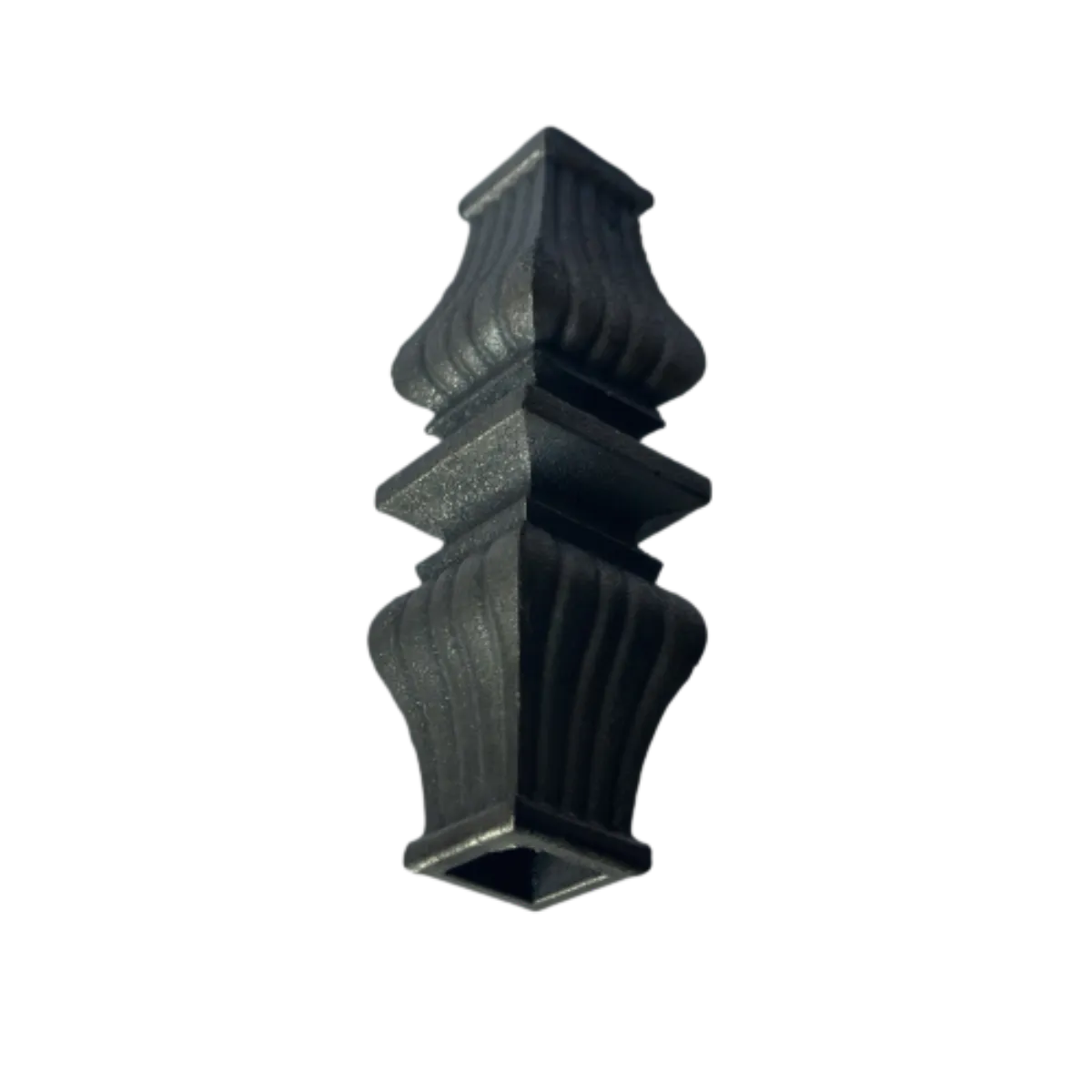

aluminium window frame section. This not only enhances energy efficiency but also contributes to a more comfortable indoor environment.Overall, decorative cast iron elements are a timeless and elegant choice for adding beauty and charm to any space. Whether used in building facades, furniture, or art pieces, cast iron elements are sure to make a lasting impression. Their durability, versatility, and intricate designs make them a popular choice for architects, designers, and artists alike. So next time you're looking to add a touch of elegance to your home or building, consider incorporating decorative cast iron elements into your design.

Ensure that the chose aluminum profile meets the design specifications, including the required quality, structural, aesthetics, finish and compatibility with other building materials.

What Is the Difference Between Aluminum & Wrought Iron?

Ornamental cast iron panels are an exquisite fusion of art and functionality, delivering both aesthetic appeal and structural integrity. Used in architectural designs, garden enclosures, and decorative elements, these panels bring a vintage charm to modern constructions while preserving a sense of history and craftsmanship.

In addition to being durable, grey iron panel is also incredibly versatile. It can be easily customized to fit any space or design preference, with options for different heights, widths, and decorative elements. Whether you are looking for a simple and classic panel design or a more ornate and intricate pattern, grey iron panel can be tailored to suit your needs.

grey-iron-panel

Energy Efficiency

In a nutshell, the main difference between these two types of surface finish is the oxide layer. Anodized finish has a layer of oxide, whereas mill finish does not have the oxide layer.

The vertical sliding aluminium window replicates the look of traditional sash windows, an obvious solution for those in homes wishing to replicate existing sash windows.

At present, the surface treatment methods for aluminum profiles used in doors and windows mainly include anodizing, electrophoresis, powder coating, and wood grain powder coating. Different surface treatments have different appearance quality inspection standards.

What are the aluminium window opening types?

To address this issue, homeowners can opt for aluminum windows with thermal breaks or install double or triple-pane glass to improve insulation. Additionally, adding curtains or blinds to aluminum windows can help to reduce heat transfer and improve energy efficiency.

Should wrought iron be given a coat of paint?

Frequently Asked Questions

Aluminium Profile

Conclusion

- Durability Aluminum rollers are corrosion-resistant, providing longevity and reducing the need for frequent replacements.

Shape