Understanding HPMC

- 3. Additives (optional) Depending on your application, you may want to include preservatives, colorants, or active pharmaceutical ingredients (APIs).

Moreover, the use of cement bonding additives provides extended service life to constructions. By enhancing the resistance of concrete to water infiltration and chemical attacks, these additives contribute to the longevity of structures. For instance, applications in marine environments or areas with high salinity can benefit significantly from the protective qualities provided by specialized bonding additives, which prevent corrosion of reinforcements and deterioration of the concrete substrate.

5. Agriculture HPMC has gaining attention in agricultural applications as a coating for seeds and pesticides. Its film-forming properties help to increase adherence and slow the release of active ingredients, contributing to improved efficacy.

Factors Influencing HEC Pricing

Both HPMC and CMC are versatile cellulose derivatives with a wide range of applications across various industries. Their unique qualities, such as thickening, binding, and stabilizing abilities, make them invaluable in pharmaceuticals, food, cosmetics, and construction. As industries continue to seek innovative solutions and improve product formulations, the demand for HPMC and CMC is likely to grow. Understanding the properties and applications of these compounds is essential for professionals involved in product development and formulation, ensuring they harness their full potential in creating high-quality products.

5. Reduction in Dust Generation During application, putty powder can generate dust, which poses health risks to workers and can contaminate the environment. The incorporation of HPMC helps to bind the powder more effectively, reducing dust generation and creating a safer work environment.

Additionally, MHEC exhibits excellent water retention and film-forming capabilities. This means it can help maintain moisture in products, which is vital in applications such as construction materials or personal care products. The ability to create a flexible and durable film makes MHEC particularly valuable in coatings and adhesives, where adhesion and protection against environmental factors are crucial.

- 2. Deionized or distilled water

4. Hydration Allow the mixture to hydrate for a specific period, usually between 30 minutes to several hours, depending on the concentration and the specific properties of the HPMC. During this time, the HPMC particles absorb water and swell, ultimately dissolving to form a viscous solution.

Exploring HPMC Formulation A Comprehensive Overview

Conclusion

1. Quality and Purity The quality of HPMC is paramount, particularly in applications related to food and pharmaceuticals. Ensure you source HPMC from reputable manufacturers who can provide certification regarding the product’s purity and absence of harmful contaminants. Testing results and compliance with international standards, such as FDA or EU regulations, are crucial indicators of quality.

One of the most notable characteristics of HEC is its ability to form stable solutions at different pH levels and temperatures. This stability is crucial for many industrial applications, allowing products to maintain consistent performance regardless of environmental conditions. Dow’s HEC products are also characterized by their low toxicity and environmentally friendly profile, making them suitable for a wide range of applications.

Hydroxypropyl Methylcellulose (HPMC), a versatile cellulose derivative, has gained significant attention in various sectors, such as pharmaceuticals, food, and cosmetics. One of its critical applications lies in the formulation of Sodium Dodecyl Sulfate (SDS) products, a widely used anionic surfactant. This article explores the characteristics of HPMC, its interaction with SDS, and the implications of this combination in different industrial applications.

HEC is derived from naturally occurring cellulose and is soluble in water, which makes it a prominent choice in numerous formulations. It is widely used in the cosmetics and personal care industry as a thickening agent, in pharmaceuticals for drug formulation, and in construction materials as a water-retention aid. Its unique ability to form gels, stabilize emulsions, and modify viscosity makes it a valuable ingredient in various products.

Hydroxyethyl cellulose (HEC) is a non-ionic water-soluble polymer derived from cellulose, the most abundant organic polymer on Earth. This versatile compound has garnered significant attention due to its unique properties and wide array of applications across various industries. In this article, we will explore the properties, applications, and benefits of HEC cellulose.

3. Open Time Extension HPMC increases the open time of tile adhesive, meaning that the adhesive remains workable for an extended period after application. This feature is crucial for large-scale projects or intricate tiling patterns where precise placement and adjustments are necessary before setting the tiles.

The incorporation of cement adhesive additives into construction projects offers multiple benefits. Firstly, they improve the overall durability and longevity of constructions, which can save costs associated with repairs and maintenance in the long run. Secondly, these additives can enhance the mechanical properties of cement, resulting in stronger and more reliable structures.

Hydroxypropyl Methyl Cellulose (HPMC) A Versatile Polymer in Chinese Industry

HPMC Stands For Understanding Hydroxypropyl Methylcellulose

Conclusion

Structure and Properties

Understanding HPMC Grades and Their Influence on Viscosity

In conclusion, the China HPMC factory exemplifies the intersection of innovation, quality manufacturing, and global market dynamics. As the demand for HPMC continues to grow, the role of Chinese manufacturers in supplying high-quality, versatile products is crucial. Their commitment to research and development, coupled with sustainable practices, positions them as leaders in the HPMC industry. As they navigate challenges and seize opportunities, Chinese HPMC factories will undoubtedly continue to shape the landscape of this essential market segment in the coming years.

Conclusion

Hydroxypropyl methylcellulose is a multifunctional ingredient pivotal to numerous industries. Its adaptability in pharmaceuticals, food, construction, and cosmetics demonstrates its broad utility and importance. As research continues to unveil new applications and benefits of HPMC, its role in developing innovative, effective, and eco-friendly products is likely to expand even further, meeting consumer demands for quality and sustainability.

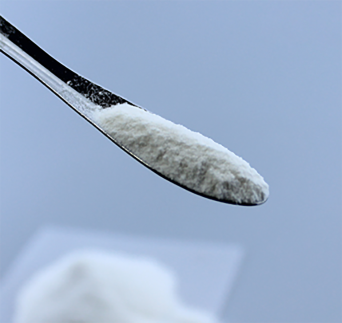

Hydroxypropyl methylcellulose (HPMC) is a synthetic polymer derived from cellulose. Its unique properties make it an essential ingredient across various industries, from pharmaceuticals and food production to construction and personal care products. One of the significant characteristics of HPMC is its viscosity, which can greatly affect its application in different formulations. Understanding the grades of HPMC and how they influence viscosity is crucial for optimizing performance in various uses.

The combination of HPMC and CMC can create a synergistic effect, enhancing their individual properties for better performance in practical applications. In the pharmaceutical industry, HPMC is often employed in the formulation of tablets and capsules, serving not only as a binder but also as a stabilizing agent. When combined with CMC, the gel-forming properties of the combination can lead to improved drug delivery systems, allowing for sustained drug release and better bioavailability.

hpmc cmc

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer derived from cellulose. It is a non-ionic, water-soluble derivative of cellulose that has gained popularity in various industries due to its remarkable properties, including thickening, emulsifying, and film-forming capabilities. HPMC is produced through the chemical modification of cellulose, specifically by etherifying it with propylene oxide and methyl chloride. This article explores the different HPMC types, their unique properties, and their diverse applications.

4. Stabilizer It helps to stabilize emulsions and suspensions in cosmetic and food products.

Conclusion

Reduction of Shrinkage and Cracking

Redispersible Polymer Powder is a water-soluble dispersible powder, which is divided into ethylene/vinyl acetate copolymer, vinyl acetate/tertiary vinyl carbonate copolymer, acrylic copolymer, and so on, and the powder adhesive is made by spray drying, and the polyvinyl alcohol is used as the protective colloid. This powder can be quickly re-dispersed into emulsion after contact with water, due to the high bonding capacity and unique properties of re-dispersible latex powder.

Future Prospects

4. Reduced Shrinkage and Cracking Using cement adhesive additives can help minimize shrinkage and cracking during the curing process. This characteristic is vital in preventing structural damage and ensuring long-term stability for various construction applications.

cement adhesive additive

Applications in Construction

Cosmetic Applications

Quality Standards and Production Practices

Preparing an HPMC solution requires precision and attention to detail to ensure optimal results. By following the outlined procedures, users can achieve a high-quality solution suitable for their specific needs. Understanding the properties of HPMC and the correct preparation techniques will ultimately enhance the performance and reliability of the final products in various applications. Whether for pharmaceutical formulations or industrial uses, mastering HPMC solution preparation is a vital skill that can contribute significantly to product success.

3. Construction In the construction sector, HPMC is an additive in cement and mortar, improving workability and water retention. This is critical in ensuring that construction materials adhere to walls and surfaces properly.

The push for innovative materials in the construction sector presents opportunities for HPMC. With the rise of green building certifications and eco-friendly construction practices, HPMC can be a key component in developing materials that meet modern sustainability standards.

Conclusion

One of the most significant trends influencing the HPMC market is the growing demand for HPMC in the pharmaceutical sector. HPMC is commonly used in the production of controlled-release formulations and as a coating agent for tablets. As the global pharmaceutical industry continues to expand, driven by an aging population and increased health awareness, the demand for high-quality excipients like HPMC is projected to rise substantially.