Before you start cleaning, it’s essential to let the cast iron cool down. Plunging hot cookware into cold water can cause it to crack. Allow the skillet or pot to gradually return to a manageable temperature, which also makes handling it easier.

After your camping trip, remember to inspect your cast iron before storing it away for the next adventure. If you notice any rust spots, they can be scrubbed away with a little steel wool, followed by a re-seasoning process. Regular maintenance ensures your cast iron cookware remains effective for years to come.

In the realm of textile manufacturing, efficiency and precision are paramount. Among the plethora of sewing machines available, industrial overlock sewing machines have carved a niche for themselves, becoming indispensable tools in the garment industry. These machines, often referred to as sergers or overlockers, perform a unique function that significantly enhances the quality of fabric seams and the overall durability of garments.

One of the primary benefits of using a double needle is its ability to create a parallel stitch effect, reminiscent of professional finishings often seen in ready-to-wear garments. This parallel stitching is not only aesthetic but also strengthens seams, making them more durable. This makes double needles particularly popular when working with knit fabrics, as they can help prevent the fabric from stretching or puckering during the sewing process.

Sewing enthusiasts and professionals alike often encounter challenges when working with thick fabrics. Whether it’s upholstery material, multiple layers of denim, or quilt batting, using the right tools is essential for achieving a high-quality finish. One such indispensable tool is the walking foot. This specialized sewing machine attachment has garnered a reputation for revolutionizing the way we handle thick fabrics, making it a must-have for anyone serious about sewing.

Applications

The primary advantage of using a walking foot is the improved fabric control it provides. When working with thick fabrics, the risk of uneven sewing increases due to the bulk of the material. A walking foot helps to maintain an even stitch length, minimizing the risk of puckering or distortion that can occur when multiple layers are sewn together.

One of the most significant advantages of using automatic bag closer machines is the enhancement of operational efficiency. Manual sealing processes can be time-consuming and prone to human error, potentially leading to product spoilage or contamination. By automating the sealing process, businesses can significantly reduce the time taken to package products and can allocate labor to other critical areas of production.

Conclusion

Heavy duty machines typically have higher maximum sewing speeds, around 1500 stitches per minute, versus 1000-1200 stitches per minute for standard machines. Again, this allows them to work through heavy fabrics more efficiently. However, heavy duty machines also tend to sew better at slower speeds, in the 500-800 stitch per minute range, for optimal control through thick seams. So they provide a wider speed range to suit the fabric.

- Keychains Small and manageable, perfect for learning basic stitches.

Applications

Investing in the right beginner leather sewing machine can make all the difference in your crafting journey. With the right tools and some practice, you can create beautiful and functional leather projects that showcase your creativity. Remember to enjoy the process, and don’t hesitate to seek out tutorials and community support as you embark on this exciting adventure. Happy sewing!

Applications

Applications in the Fashion Industry

Conclusion

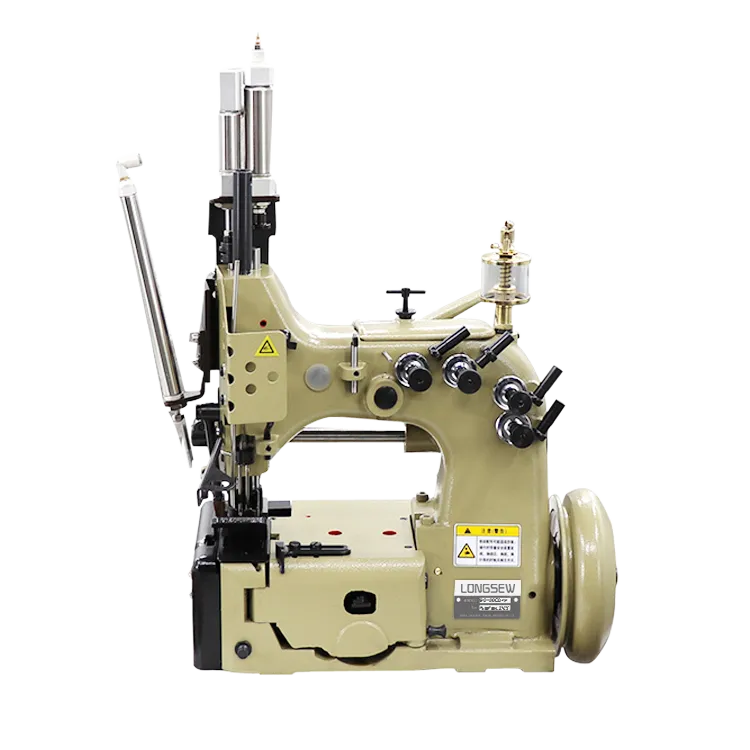

3. Stitching Machines For bags made of fabric or paper, stitching machines are often employed. These machines sew the edges together using thread, providing a robust and flexible seal. This method is especially suited for heavy or bulk materials where additional strength is necessary.

Materials You’ll Need

Beyond hem stitching, twin needle sewing machines can be employed for decorative purposes. By choosing different thread colors for each needle, sewists can add unique flair to their projects. This technique is particularly popular in quilting, where multiple colors of thread can enhance the design and add dimension to the quilt top. Similarly, embellishing items such as tablecloths or quilts with intricate patterns becomes much easier with the dual-needle approach.

twin needle sewing machine

Upholstery is a craft that combines both art and functionality, giving life to furniture and enhancing the overall aesthetics of a space. Among the various tools used in upholstery, the hand sewing machine plays a vital role, allowing artisans to create intricate designs and durable finishes. This article explores the significance of upholstery hand sewing machines, their features, and how they preserve the rich tradition of upholstery craftsmanship.

In the realm of textile manufacturing, efficiency and precision are paramount. Among the plethora of sewing machines available, industrial overlock sewing machines have carved a niche for themselves, becoming indispensable tools in the garment industry. These machines, often referred to as sergers or overlockers, perform a unique function that significantly enhances the quality of fabric seams and the overall durability of garments.

B. Leatherwork and Accessories:

Readers will discover ideas for crafting leather bags, wallets, belts, and other accessories using thecapabilities of a heavy duty sewing machine.

To get started with chain stitching, one needs basic sewing tools fabric, appropriate thread, and a sewing machine or needle for hand stitching. Selecting the right type of thread is crucial, as the thread should complement the fabric’s texture and weight. The proper tension settings on the sewing machine are essential for achieving a flawless chain stitch and preventing issues like thread breakage or puckering.

Sewing has long been an essential skill, whether for basic repairs, crafting unique garments, or pursuing a hobby that sparks creativity. Modern advancements in sewing technology have made the process more efficient and enjoyable. One feature that stands out in contemporary sewing machines is the automatic bobbin winder. This innovative tool has revolutionized the way sewing enthusiasts and professionals approach their craft, providing numerous advantages that simplify the sewing experience.

Understanding the Industrial Chain Stitch Machine A Key Player in Textile Manufacturing

1. Labor Costs The wage of the operators who run the machines is a significant component. Skilled machinists who can effectively operate overlock machines may command higher wages due to their expertise.

In addition to its durability, the CB4500 also offers a range of advanced features that make sewing with leather a breeze. The machine is equipped with a powerful needle feed system that ensures precise stitching and prevents the material from shifting or bunching up during sewing. This feature is particularly useful when working with thick or slippery leather materials that can be difficult to control.

cb4500 leather sewing machine

Chain stitch sewing machines have become a fundamental tool in the textile and garment industry, renowned for their unique stitching technique and versatility. This specialized machinery creates a series of interconnected loops, forming a chain-like pattern that is not only strong but also offers significant elasticity. Introduced in the 19th century, chain stitch machines have evolved over the years, integrating modern technology while retaining their original charm and functionality.

One of the primary advantages of using a double needle lockstitch machine is the efficiency it brings to production processes

. By sewing two lines of stitches at once, manufacturers can significantly reduce the time required for assembly, which translates to increased productivity. Furthermore, the machine's ability to create consistent and secure seams minimizes the need for post-sewing corrections, thereby streamlining the entire manufacturing workflow.Automatic shoe sewing machines incorporate various technologies such as computer numerical control (CNC), robotics, and artificial intelligence (AI). This integration allows for precise stitching patterns, automated fabric feeding, and real-time quality control. One of the key advantages of these machines is their ability to handle complex tasks with minimal human intervention, resulting in significant reductions in labor costs and production time.