- .

Advancements in shale shaker screen technology have led to the development of innovative solutions that enhance their efficiency and durability. The following are some notable advancements:

- .

Qu'est-ce que la grille en acier carbone dentelée ?

Shaker screens are available in various types, each designed to meet specific operational requirements and address different challenges encountered during drilling operations. The most common types of shaker screens include:

- .

Galvanised Steel Grid A Durable Solution for Modern Infrastructure

Edelstahl Gehwege Langlebigkeit und Ästhetik

1. Material Quality The price of stainless steel bar grating largely depends on the quality of the stainless steel used. Grades 304 and 316 are the most common, with 316 being more resistant to chloride, making it more desirable for coastal or marine environments. Consequently, this higher resilience comes at a premium price.

- .

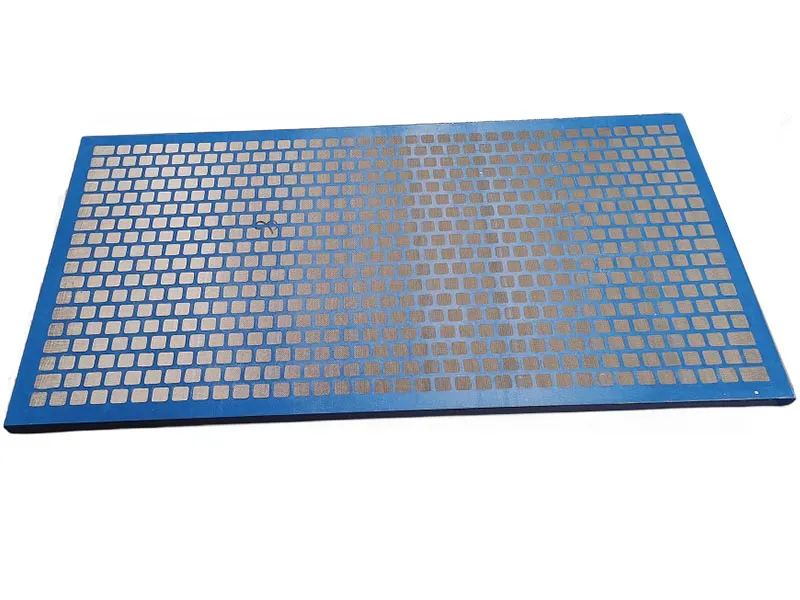

Composite Screens: Composite screens are made of a combination of materials, such as metal and synthetic fibers, to provide enhanced durability and separation efficiency. These screens are ideal for drilling operations in harsh environments or with abrasive drilling fluids. Composite screens offer improved resistance to wear and tear, ensuring longer service life.

Conclusion

Galvanized steel grating has a glossy appearance and finish. Due to its advantages, it is well suited for industrial use. The following are some of the benefits of galvanized steel grating.