5% thread overlockers refer to machines that are designed to use 5% thread with a specific configuration that optimizes stitch quality and fabric handling. These machines often come with the ability to handle various types of fabric, from lightweight cotton to heavier knits, making them versatile for a range of sewing projects.

In the world of carpet manufacturing and retail, efficiency and quality are paramount. One of the essential tools for ensuring a high-quality finish and durability in carpet production is the carpet overlocking machine. As the demand for professional-looking carpets continues to rise, the need for advanced overlocking machines has become increasingly significant. This article will explore what carpet overlocking machines are, their benefits, and what to consider when looking for one for sale.

Conclusion

5. Take Your Time Patience is key. Taking your time while sewing will enhance the quality of your work and ensure that each seam is neatly finished.

In conclusion, the FIBC sewing machine head plays a pivotal role in the manufacturing process of Flexible Intermediate Bulk Containers. Its advanced engineering and technology contribute to producing high-quality, robust, and reliable bags that meet the varied needs of industries worldwide. As the demand for efficient and sustainable packaging solutions continues to grow, investing in high-performance sewing machine heads will be essential for manufacturers looking to stay ahead in the competitive market. By embracing innovation and prioritizing quality, the future of FIBC production looks promising, paving the way for more efficient and sustainable industrial practices.

2. Thread Opt for strong, heavy-duty thread like polyester or nylon. These threads are less likely to break under strain and will hold up against the robust fabric.

Leather sewing machine belts are usually made of high-quality materials such as rubber or synthetic materials that are designed to withstand the rigors of sewing heavy-duty materials like leather. These belts are responsible for transferring power from the motor to the needle, allowing the machine to sew smoothly and efficiently.

Nevertheless, the rise of auto sewing is not without its challenges. One of the primary concerns is the impact on employment. As companies invest in automated solutions, there is apprehension regarding job displacement for skilled workers. While it is true that some roles may diminish, it is essential to consider that the industry will also create new opportunities in machine maintenance, programming, and design. Upskilling and reskilling programs will be vital to prepare the workforce for this evolving landscape.

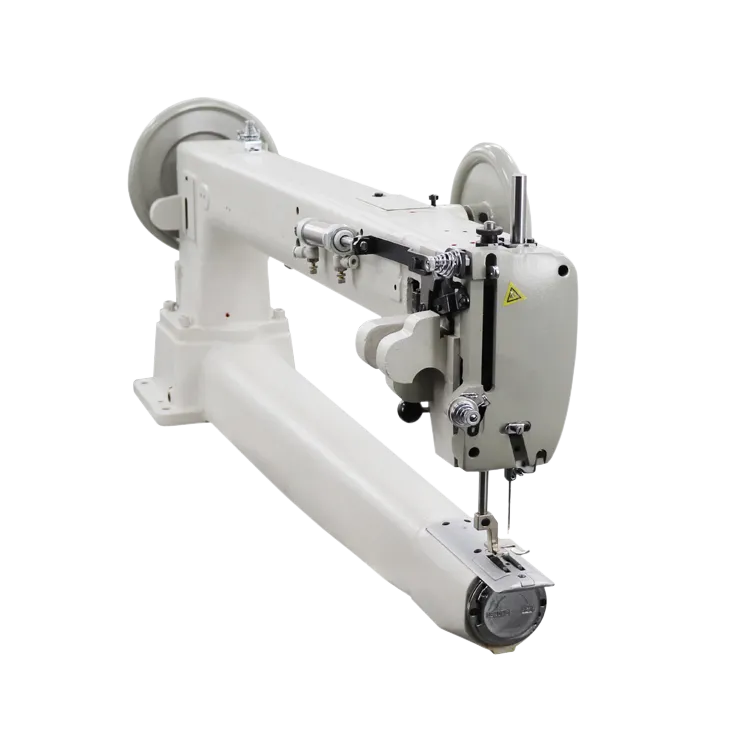

3. Cylinder-Bed Machines These machines are designed for working on tubular or circular leather items, such as sleeves or hems. Their unique design allows for flexibility and ease of operation when handling leather that may be difficult to manage on a flatbed machine.

Historically, upholstery was done by hand, a time-consuming method that often resulted in variability in quality. The introduction of upholstery stitching machines revolutionized the industry, allowing for greater consistency and speed in production. These machines can execute complex stitch patterns and handle thicker materials that would be challenging for manual sewing. With the capability to sew through multiple layers of fabric or leather, upholstery stitching machines ensure that seams are strong and can withstand the everyday wear and tear of furniture use.

Maintenance Tips

Applications Across Industries

How Much Space Do I Need For A Sewing Machine?

Conclusion

4. Price Industrial sewing machines generally have a higher upfront cost. However, considering their durability and functionality, they may provide better value for avid sewists or small business owners.

When looking for an industrial machine for sewing leather, there are a few key features to consider. The first is the type of needle system the machine uses. Leather requires a specific needle type, such as a wedge point needle, that can penetrate through the material without causing damage or distortion.

Using Twin Needles in Embroidery