3. Versatility This technique can be applied to a wide range of fabrics, particularly knit and stretch materials. Whether you're sewing casual t-shirts, activewear, or even some types of woven fabrics, the coverstitch will deliver impressive results.

The lock stitch formation occurs in three main steps

1. Enhanced Creativity By allowing for multiple lines of stitching in different colors, dual needle sewing machines empower sewists to unleash their creative potential. The ability to combine different thread colors can add depth and texture to fabric, enhancing the overall design.

Considerations and Maintenance

Tips for Choosing a Heavy Duty Sewing Machine

One of the primary advantages of using specialized FIBC sewing machine heads is their ability to produce high-quality, consistent seams. Seam integrity is vital for maintaining the load-bearing capacity of FIBCs, as weak seams can lead to catastrophic failures that compromise safety and increase material loss. Advanced features such as automatic thread trimming, programmable stitching patterns, and adjustable tension settings allow for adaptability across various production needs.

2. Pillow Covers

4. Speed Many lockstitch machines are designed for high-speed sewing, enabling manufacturers to boost productivity. Faster sewing speeds translate to increased output, which is vital in a competitive market.

Benefits of Using Double Needle Sewing Machines

use of double needle sewing machine

In summary, the 3-needle chain stitch machine serves as an invaluable asset in the textile industry, enabling manufacturers to produce garments that meet the demands of durability, quality, and aesthetics. As the fashion and textile markets continue to evolve, the use of advanced machinery like the 3-needle chain stitch machine will undoubtedly remain pivotal in shaping the future of garment manufacturing. Embracing such technology not only enhances production capabilities but also ensures that companies can deliver high-quality products to consumers, meeting their ever-growing expectations for performance and style.

2. Furniture Manufacturing: For stitching thick upholstery fabric or leather used on sofas, chairs, and other furniture, heavy duty machines greatly improve production efficiency and product quality.

What is a Commercial Upholstery Sewing Machine?

Triple feed sewing machines take the capabilities of compound feed machines a step further by incorporating an additional feed mechanism. In a triple feed system, the needle feed, drop feed, and walking foot work in tandem with an upper feed mechanism. This setup provides even greater control over fabric movement, making it ideal for intricate and demanding sewing tasks.The primary advantage of triple feed sewing machines is their superior handling of challenging materials. The combined action of the four feed mechanisms ensures precise fabric control, even when working with slippery or stretchy fabrics. This makes triple feed machines an excellent choice for sewing items such as automotive interiors, marine upholstery, and heavy-duty outdoor gear.Triple feed sewing machines also excel in maintaining stitch consistency. The additional feed mechanism enhances the machine’s ability to produce uniform stitches, regardless of fabric type or thickness. This level of precision is essential for achieving high-quality results in complex sewing projects.

2. Pillow Covers

What Makes Heavy Duty Sewing Machines Different?

In today's fast-paced world, convenience and efficiency are key factors that many consumers consider when purchasing sewing machines. Among the various innovations in the industry, self-threading sewing machines have emerged as a popular choice for both beginners and seasoned crafters alike. With the ability to simplify the threading process, these machines save time and reduce frustration, making sewing projects more enjoyable. In this article, we will explore the benefits of self-threading sewing machines and where to find them for sale.

Conclusion

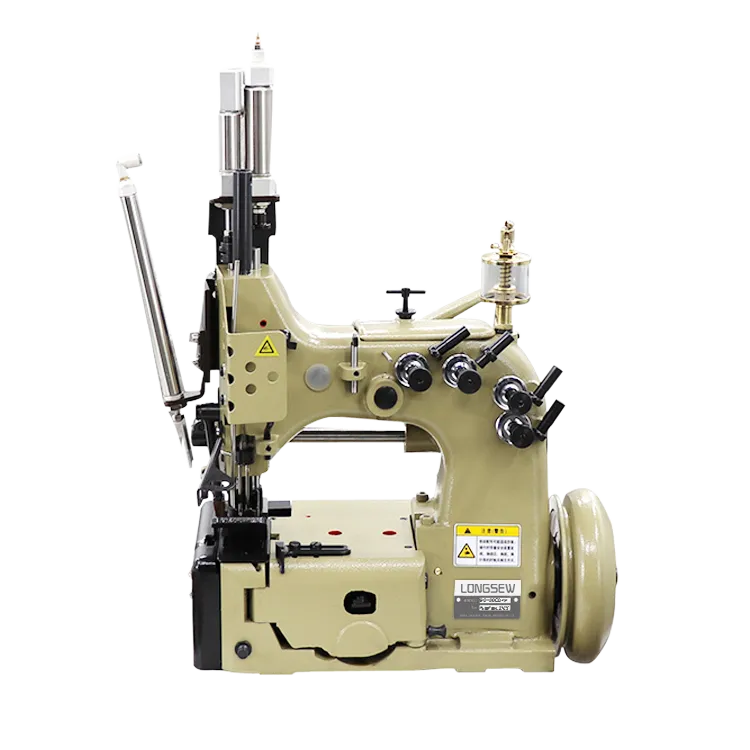

The Importance of Bulk Bag Sewing Machines in Modern Manufacturing

Quality and Aesthetic Enhancement

The lockstitch is formed by a combination of two threads the top thread, which is typically fed from the sewing machine’s needle, and the bobbin thread, which is located beneath the fabric. When the needle penetrates the fabric and completes its upward motion, the hook in the sewing machine catches the needle thread and loops it around the bobbin thread. This process tightly interlocks the two threads, forming a secure and balanced stitch.

In conclusion, understanding the distinct roles of coverstitch and overlock machines can significantly enhance a sewist’s repertoire. By investing in these powerful tools, one can turn ordinary fabric into outstanding garments that boast both durability and style. Whether you are a hobbyist seeking to elevate your creations or a professional aiming for perfection, integrating these machines into your workflow will undoubtedly yield satisfying results and inspire creativity in your sewing projects.

1. Heavy-duty Construction The machine must be built to withstand the stress of sewing thick woven materials. A robust frame and quality components are crucial for longevity and reliability.

woven sack bag sewing machine

- Budget Heavy-duty machines come in a range of prices. Determine your budget before researching models to find one that offers the best value for your needs.

Moreover, the Zig Zag Dressmaker sewing machine is designed with durability in mind. Constructed from high-quality materials, these machines are built to withstand the rigors of frequent use. This resilience is particularly important for those who engage in sewing as a hobby or profession, ensuring that the investment in a good sewing machine pays off in the long run. Additionally, many models are designed with user-maintenance features, allowing for easy cleaning and upkeep, which further extends their lifespan.

1. Needle Insertion The process begins with the needle penetrating the fabric, bringing the top thread through the fabric layers.