- In healthcare facilities, the role of floor tape transforms. It becomes a critical tool in infection control, marking socially distanced queues, patient waiting areas, and directional paths to maintain hygiene protocols. The tape's easy-to-clean surface makes it ideal for maintaining cleanliness standards in these sensitive environments.

- 2. Cost-Effective Compared to other insulation materials, wire wrap tape is relatively inexpensive and easy to install, making it an economical choice for many automotive applications.

In summary, yellow insulation tape is a multifaceted tool with a broad range of applications. From ensuring electrical safety and marking hazardous areas to sparking creativity in artistic endeavors, its versatility is evident. Whether you are an electrician, a safety officer, or a DIY enthusiast, yellow insulation tape can enhance your work and projects significantly. As you explore its uses, you will find that this simple product holds a wealth of potential, making it an indispensable companion in both industrial and creative settings. So next time you reach for a roll of insulation tape, consider the vibrant yellow option—not just for its functionality, but also for the touch of creativity and safety it brings to your projects.

(4) Water absorption 0.9% (46 hours in H20 at 21 ℃)

What is Polyethylene Tape used for?

J50 High-voltage EPR Rubber Tape

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.

Flex Tape 4 is also easy to use. Simply cut the desired length of tape, peel off the backing, and apply it to the surface that needs repairing. The tape will bond instantly, creating a strong and durable seal that will hold up over time. No additional tools or materials are required, making Flex Tape 4 a convenient and cost-effective solution for DIY projects.

Black PVC tape is renowned for its durability. It is resistant to moisture, chemicals, and UV rays, making it suitable for use in various conditions. Whether used indoors or outdoors, the tape withstands the rigors of different environments. This weather resistance is particularly important for outdoor electrical work, as exposed wires can be vulnerable to the elements. Using black PVC tape helps protect these wires, ensuring they function safely and effectively over time.

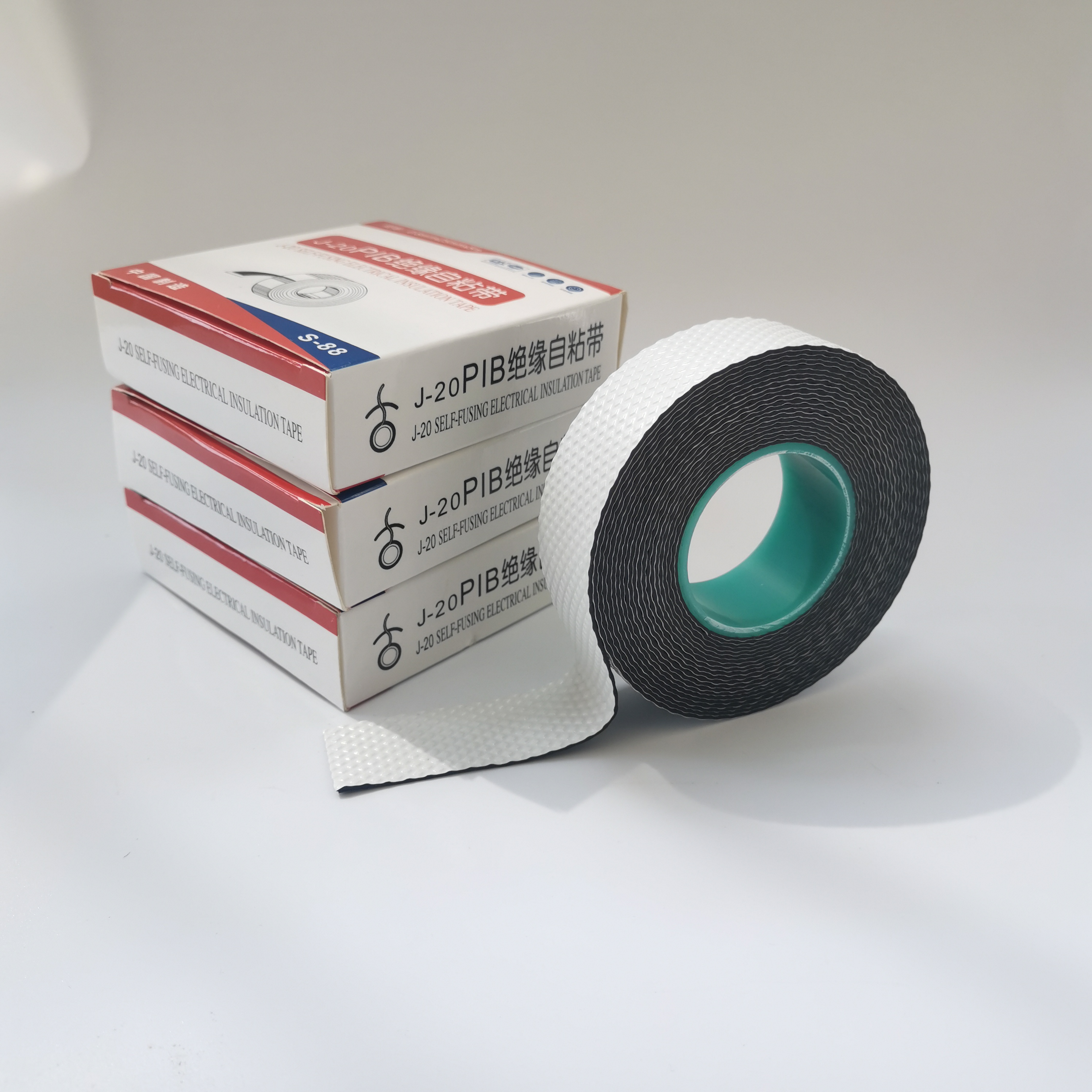

PlB self-amalgamating Tape

7. Cost-Effectiveness While the initial investment in butyl rubber roofing sheets may be higher compared to some traditional materials, their longevity and low maintenance requirements often result in cost savings in the long run. Less frequent replacements and repairs mean lower total ownership costs.

Butyl rubber waterproofing is a popular method used to protect various surfaces from water damage. This type of waterproofing involves the application of a special butyl rubber compound that creates a durable and impermeable barrier against moisture. Whether used in construction projects, industrial applications, or even in residential settings, butyl rubber waterproofing offers a reliable solution for preventing water intrusion and preserving the integrity of buildings and structures.

3. Automotive Repairs Car enthusiasts have also found this tape useful for temporary fixes, such as covering a damaged hose or sealing a leaking coolant reservoir, allowing for safe driving until proper repairs can be made.

what is rubber splicing tape used for. The tape can be used to repair damaged hoses, gaskets, and seals, as well as to provide insulation and protection for electrical components. This helps to extend the lifespan of the equipment and ensure its safe and reliable operation.