1. Enhanced Professional Appearance One of the primary benefits of using a double needle machine is the professional finish it provides. The two parallel stitch lines not only look aesthetically pleasing but also add durability to hems and seams, making garments less likely to unravel over time.

In conclusion, twin needle sewing is a valuable technique that serves multiple purposes in the sewing world. From creating stretchy hems in knit fabrics to adding decorative details and enhancing the durability of seams, this method is an essential tool for anyone looking to refine their sewing skills. Whether you're a beginner or an experienced sewist, mastering twin needle sewing can open new doors for creativity and precision in your sewing projects. By utilizing this technique, you can achieve professional-looking results that showcase your craftsmanship and elevate your handmade creations.

2. Stitch Options A good computerized sewing machine should offer a variety of stitch options. Look for machines that offer utility stitches, decorative stitches, and quilting stitches. This versatility allows you to tackle various projects, from clothing to home decor.

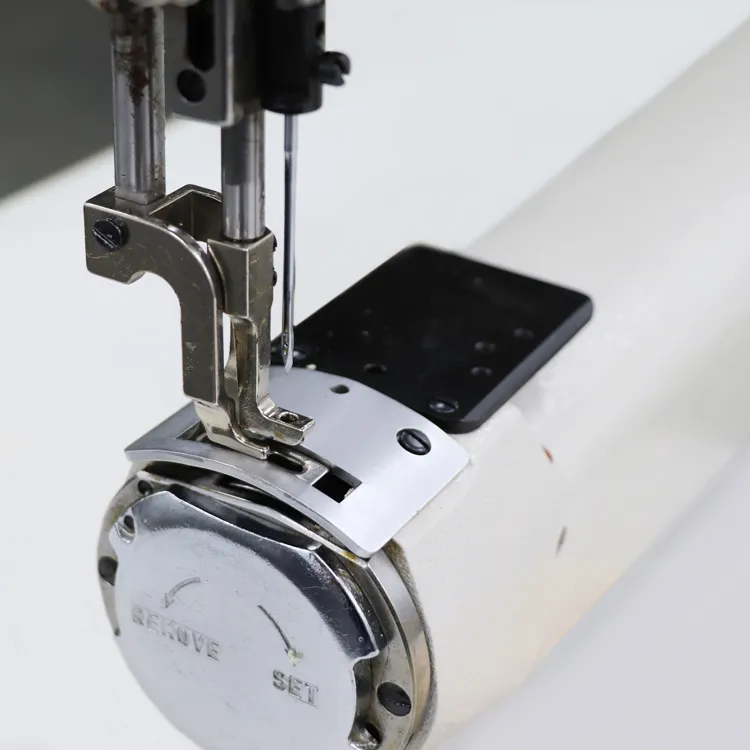

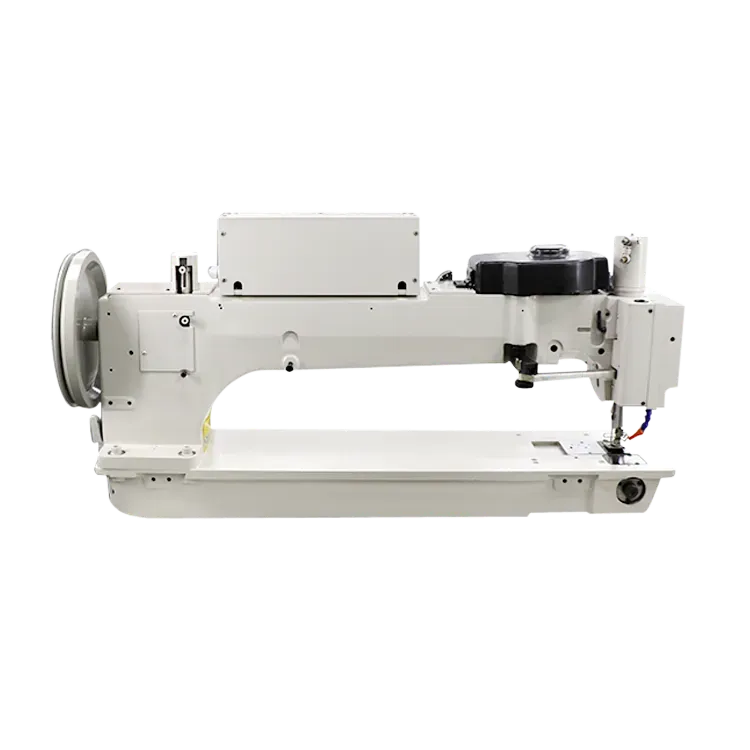

Leather is a robust and unforgiving material that requires a specific sewing machine, often referred to as a heavy-duty or industrial sewing machine. These machines are equipped with more powerful motors, reinforced frames, and often come with specialized walking feet or feed dogs to help manage the thickness and texture of leather. Additionally, using the right needle is crucial when sewing leather; a leather needle is specifically designed to penetrate this dense material without causing damage.

The Evolution of Leather Sewing Machines

Improved Consistency

One of the most significant advantages of an automatic needle threader is the time it saves. For many, threading a needle can be a frustrating task, especially for those with limited vision or dexterity. The automatic needle threader eliminates this hassle, allowing users to focus on the creative aspects of sewing rather than struggling with a small piece of thread and a tiny eye. With the mere push of a button or a gentle tug on the thread, the machine takes care of this step, making the entire process more efficient.

Moreover, these machines are engineered for durability and performance. Commercial models are often built with robust components that can withstand the rigors of frequent use, making them ideal for businesses that rely on speed and accuracy. Users can sew through multiple layers of thick fabric or delicate materials without compromising stitch quality, thanks to enhanced feed mechanisms and powerful motors.

The Sailmaker Sewing Machine A Vital Tool for Maritime Craftsmanship

Tension Control:

Heavy-duty mechanical sewing machines are designed to tackle a variety of fabrics, including denim, canvas, leather, and multiple layers of material. Unlike their lightweight counterparts, these machines are built with robust internal components that ensure durability and longevity. Often equipped with a powerful motor, they can sew through thick materials with ease, preventing jams and ensuring a smooth operation. The metal frame further enhances stability, allowing for precise stitching, even at high speeds.