Lithopone was developed in the 1870s as a substitute for lead carbonate (lead white), to overcome its drawbacks of toxicity and poor weathering resistance. Within a few years, titanium dioxide displaced lithopone to become the white pigment (PW6) par excellence in the industry and the world’s best-selling inorganic pigment. However, titanium is a product whose price is subject to large price variations due to product availability. These price increases affect the competitiveness of finished products, and so the search for an alternative to titanium dioxide has generated a variety of possibilities to optimise its use.

Specific gravity:

This can help ensure that you receive consistent quality and reliable delivery times This can help ensure that you receive consistent quality and reliable delivery times

This can help ensure that you receive consistent quality and reliable delivery times This can help ensure that you receive consistent quality and reliable delivery times lithopone(b301 b311) pricelist supplier.

lithopone(b301 b311) pricelist supplier.Additionally, market demand plays a significant role in determining lithopone pigment prices. Industries such as construction, automotive, and consumer goods have been experiencing fluctuations in demand, influencing the pricing dynamics. In periods of high demand, prices may increase as suppliers adjust to the market trends. Conversely, during downturns or oversupply situations, prices may decrease, providing opportunities for buyers to purchase at more favorable rates.

Prof Maged Younes, Chair of EFSA’s expert Panel on Food Additives and Flavourings (FAF), said: “Taking into account all available scientific studies and data, the Panel concluded that titanium dioxide can no longer be considered safe as a food additive . A critical element in reaching this conclusion is that we could not exclude genotoxicity concerns after consumption of titanium dioxide particles. After oral ingestion, the absorption of titanium dioxide particles is low, however they can accumulate in the body”.

lithopone 28~30% factories. This includes testing the purity, particle size, and brightness of the pigment, as well as conducting performance tests to assess its coverage and weather resistance.

lithopone 28~30% factories. This includes testing the purity, particle size, and brightness of the pigment, as well as conducting performance tests to assess its coverage and weather resistance.

titanium oxide tio2 manufacturers. It is essential to choose a manufacturer that has the ability to produce the required amount of titanium oxide within a specified timeframe. This ensures that there are no delays in the production process and that the product is readily available when needed.

The RGB LED panel was built ad hoc for this purpose. Measures: 23.5 × 16.5 cm. Light Intensity: 19,500.10 lux. (43.33 W in 0.2 m2) when set to solar simulation. It does not produce temperature increases in the surroundings.

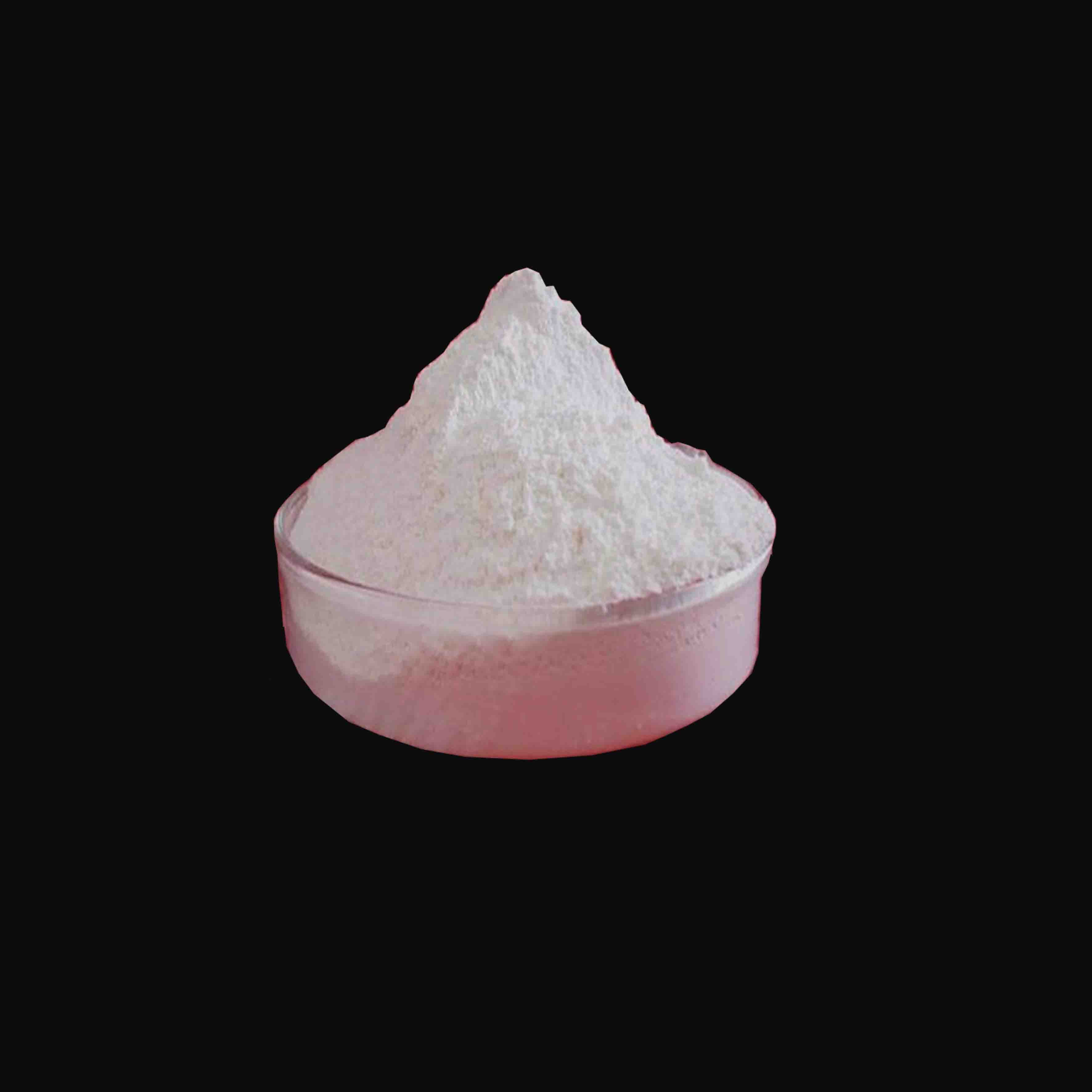

Having thus described the origin and uses of the pigment, we now come to the question, what is lithopone? It is, in short, a chemical compound usually consisting of 30.5 per cent zinc sulphide, 1.5 per cent zinc oxide and 68 per cent barium sulphate, but these proportions vary slightly in the different makes. Lithopone of this composition is sold as the highest grade, either as red seal or green seal, as it best suits the idea of the manufacturer. Many manufacturers, especially in Europe, sell and also export other brands under other seals, containing 24, 20, 18 and as little as 12 per cent of zinc sulphide with very small percentages of zinc oxide, the balance being usually barium sulphate, but sometimes certain portions of China clay or gypsum (calcium sulphate) or whiting (calcium carbonate). Such brands are not a chemical compound, but mechanical mixtures of the chemically compounded lithopone and the admixtures referred to.

For years scientists have raised concerns about the potential toxicity of titanium dioxide.

According to the EFSA's Expert Panel on Food Additives and Flavorings 2021 opinion regarding titanium dioxide, it could not rule out a concern for genotoxicity from ingestion of the material based on a perceived gap in data on this risk, which serves as the basis for current ban, said a March report on the decision.

These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards

These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards These elite manufacturers leverage cutting-edge technology, sophisticated processes, and rigorous quality control systems to deliver pigments that exceed industry standards best pigment rutile titanium dioxide manufacturers. Their rutile titanium dioxide pigments are known for their consistent color, unparalleled opacity, and optimal dispersion characteristics, ensuring seamless integration into various substrates.

best pigment rutile titanium dioxide manufacturers. Their rutile titanium dioxide pigments are known for their consistent color, unparalleled opacity, and optimal dispersion characteristics, ensuring seamless integration into various substrates.

tio2 technology manufacturers. By utilizing advanced technologies, such as nanotechnology and surface modification techniques, manufacturers are able to enhance the properties of TiO2, such as its UV resistance, dispersibility, and durability. These advancements allow TiO2 manufacturers to produce high-performance products that meet the diverse needs of their customers.

Titanium dioxide is one of the many oxides formed naturally in our environment. Manufacturers source this mined mineral from rutile, brookite, and anatase. It is then processed and refined to meet stringent safety guidelines based on the end-use for the mineral.

Additional Health Concerns Linked to Titanium Dioxide

EINECS: 215-715-5