dutch oven skillet

2. Cuisinart Chef’s Classic Enameled Cast Iron

Another benefit of using a cast iron pan is its ability to impart a unique flavor to your food. When well-seasoned, the pan develops a natural non-stick surface while enhancing the taste of grilled food. This seasoning process creates a layer of polymerized fat that not only prevents sticking but also adds a depth of flavor that is hard to replicate with non-stick alternatives.

Yemək mədəniyyətimizdə tava seçiminin önəmi böyükdür. Tava, yalnız bir alət deyil, həm də yeməklərin dadını və hazırlanma prosesini təsir edən bir vasitədir. Xüsusilə qril tavası, ət və tərəvəzlərin qril dadını vermək üçün ideal bir seçimdir. Bu məqalədə kvadrat paslanmayan dəmir qril tavası ilə ilgili müzakirə edəcəyik.

The Versatility of the 8-Quart Dutch Oven

La Padella per Pizza in Ghisa Un Must per Ogni Pizzaiolo

Another significant benefit of the cast iron shallow skillet is its versatility. This cookware can be used on the stovetop, in the oven, or even over an open flame, making it suitable for a wide range of cooking techniques. From frying and sautéing to baking cornbread or frittatas, the shallow skillet can handle it all. Additionally, the high sides of the skillet provide enough space for cooking without worrying about spills, making it an excellent choice for stir-fries or for recipes that require tossing ingredients.

Choose ingredients that will sizzle well, such as marinated meats, vegetables, or cheese. When cooking, use oils with a high smoke point to prevent burning. For best results, pre-cook your items on a grill or stovetop before placing them on the sizzler plate. This ensures they are cooked through and will not spend too much time on the plate—where they could become overcooked.

3. Incorporate the Broth Gradually add the vegetable broth, one ladle at a time, stirring frequently. Allow the rice to absorb the broth before adding another ladle. Continue this process until the rice is al dente and creamy, approximately 18-20 minutes.

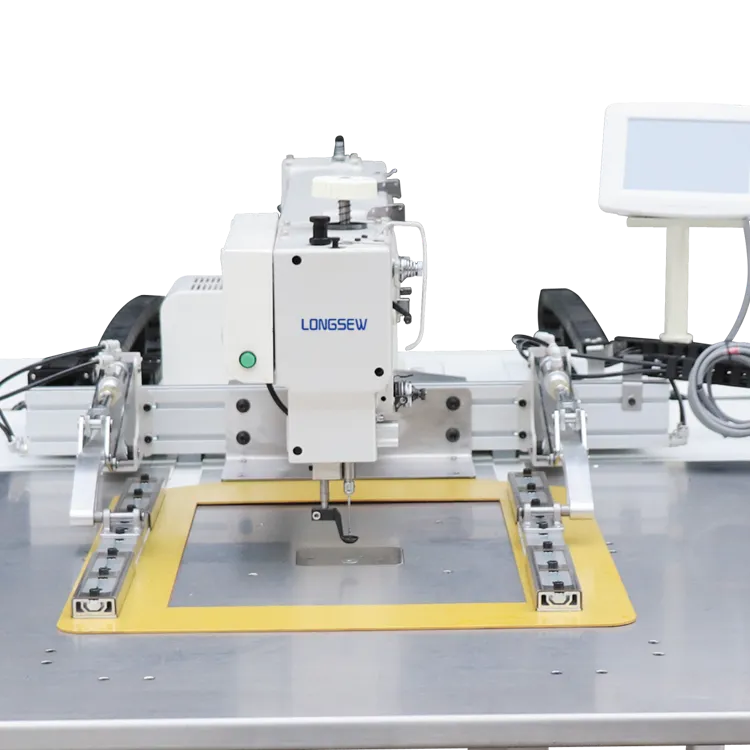

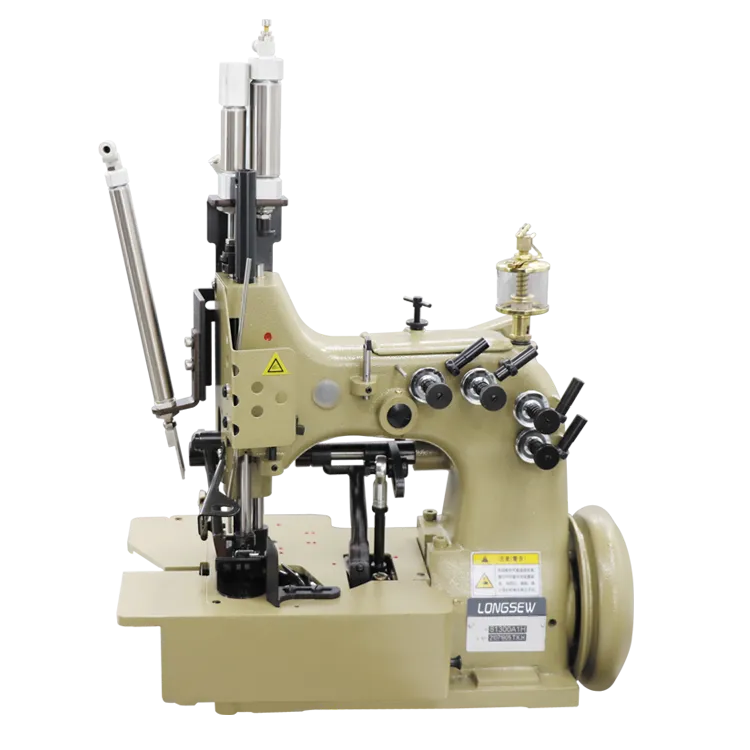

1. Type of Overlocker There are several types of overlockers on the market, each designed for specific tasks. Common types include 2-thread, 3-thread, and 4-thread overlockers. The more threads used, the more robust the stitching. Assess your production needs to determine the right type.

In conclusion, investing in a cylinder bed sewing machine can significantly enhance your sewing capabilities. From versatility and precision to ergonomic design and cost-effectiveness, these machines cater to the diverse needs of the sewing industry. As you explore the options available for sale, consider how a cylinder bed machine can transform your sewing projects and contribute to your success in this dynamic field.

For manufacturers looking to expand their capabilities, selecting the right bag closing sewing machine head is essential. Factors to consider include production volume, types of materials, and specific sealing requirements. From semi-automatic to fully automatic models, there are options available to suit different manufacturing needs.

It’s also advisable to explore the option of purchasing used quilting machines. Many experienced quilters decide to upgrade their equipment and sell their previous machines at a fraction of the original price. This can be a great way to acquire a high-quality machine without breaking the bank. However, it’s important to thoroughly examine the condition of used machines and ensure that they come with proper documentation to guarantee their reliability.

Sewing has long been regarded as a valuable skill, allowing individuals to create beautiful garments, home décor, and more. However, the complexity of threading a sewing machine often deters beginners and seasoned crafters alike from diving into this rewarding hobby. Fortunately, the advent of self-threading sewing machines has simplified this process, making it easier than ever for anyone to unleash their creativity.

Choosing the Right Machine

When considering the purchase of a single needle sewing machine, it’s essential to evaluate your own sewing needs and budget. Taking the time to research different brands, models, and features can lead to finding a machine that fits both your projects and your financial plans. Additionally, reading user reviews and seeking recommendations from experienced sewists can provide valuable insights.

The Process of Hand Stitching

Conclusion

Conclusion

When selecting upholstery machine needles, it is important to consider the type of fabric you will be working with. Different fabrics require different needle sizes and types to ensure optimal results. For example, heavy-duty fabrics such as canvas or leather require larger needles with a thicker gauge to penetrate the material effectively. On the other hand, delicate fabrics like silk or chiffon require finer needles to prevent damage to the fibers.

Projects to Consider

2. Operational Costs This includes electricity, maintenance, and other overheads associated with running the machines. Regular maintenance ensures that machines operate efficiently and can extend their lifespan.

At its core, the single needle stitch involves using a single needle to make individual stitches, which can be hand-sewn or machine-sewn. This technique is particularly favored for its ability to provide fine detail and a polished finish, making it essential in high-quality garment construction, tailoring, and decorative embroidery. When executed properly, the single needle stitch results in minimal fabric distortion, ensuring that garments fit seamlessly and have a professional appearance.

Another significant benefit is versatility; lock stitches can be used for both straight and decorative stitches, allowing for creativity in sewing projects. Lastly, sewing machines designed to create lock stitches are typically user-friendly, making them accessible for beginners while also offering advanced features for experienced sewists.

For instance, in the food industry, sealed bags help prevent contamination, prolong shelf life, and facilitate an efficient supply chain. In agriculture, the right seaming machine can secure fertilizers, seeds, and grains in a manner that protects them from environmental factors.

Next, pin or clip the fabric pieces together, ensuring everything lines up properly. Using a heavy-duty needle and the appropriate stitch type, sew the pieces together, maintaining consistent seam allowances.

Retailers have started to capitalize on this trend by offering various models of serger machines, often at discounted prices. Seasonal sales, package deals that include essential accessories, and financing options make it easier for consumers to invest in a serger. Additionally, many brands emphasize user-friendly features, which cater to beginners while also providing advanced options for seasoned sewists. Companies like Brother, Singer, and Juki have expanded their offerings to include a range of budget-friendly options that maintain high quality, attracting a diverse audience.

This systematic interaction between the needle and the bobbin creates a secure and reliable stitch that is less likely to unravel compared to other types of stitches.

Additionally, the machine’s design minimizes the likelihood of common sewing issues, such as thread breaking or tension irregularities. Many users report that the Cub Leather Sewing Machine provides consistent performance, allowing them to complete projects efficiently and to a high standard.

Additionally, the integration of modern technologies such as automation, sensors, and IoT (Internet of Things) features in bag closing machinery has revolutionized the packaging process. Automated systems can significantly reduce labor costs and improve efficiency, providing real-time monitoring and data collection for enhanced operational insights.

Understanding the Prices of Saddle Stitch Machines

Creating Pintucks and Tucks

The Learning Curve