cast iron dutch oven with tripod

In conclusion, a Dutch oven ceramic pot is an indispensable tool in the modern kitchen. Its ability to cook evenly, durability, aesthetic appeal, and easy cleanup contribute to its popularity among cooking enthusiasts. Whether you are simmering soups, roasting vegetables, or baking artisan bread, a ceramic Dutch oven will elevate your cooking experience. Investing in one not only enhances your culinary repertoire but also brings a touch of elegance to your kitchen. Overall, it stands as a testament to the perfect blend of functionality and style in cookware.

Moreover, ceramic Dutch ovens are incredibly durable. They are resistant to chipping and cracking, which means they can endure high temperatures and long cooking times without succumbing to damage. Many ceramic pots are also designed to be used on various heat sources, including stovetops, ovens, and even outdoor grills. This flexibility makes them perfect for anyone who enjoys experimenting with different cooking methods.

When it comes to oil, selecting the right type is crucial. Oils with high smoke points, such as peanut or canola oil, are ideal for deep frying. The oil needs to be heated to the right temperature, typically between 350°F to 375°F, allowing for a crispy exterior while locking in moisture and flavor.

Restoring Rusty Cast Iron A Timeless Craft

One of the most significant advantages of using a cast iron griddle is its exceptional heat retention. Once heated, cast iron maintains an even temperature, providing a perfect cooking surface for a variety of dishes. Whether you’re frying bacon for breakfast, sizzling up some steaks for dinner, or making pancakes for the whole family, you can count on your griddle to deliver consistent results every time.

Kullanım Alanları

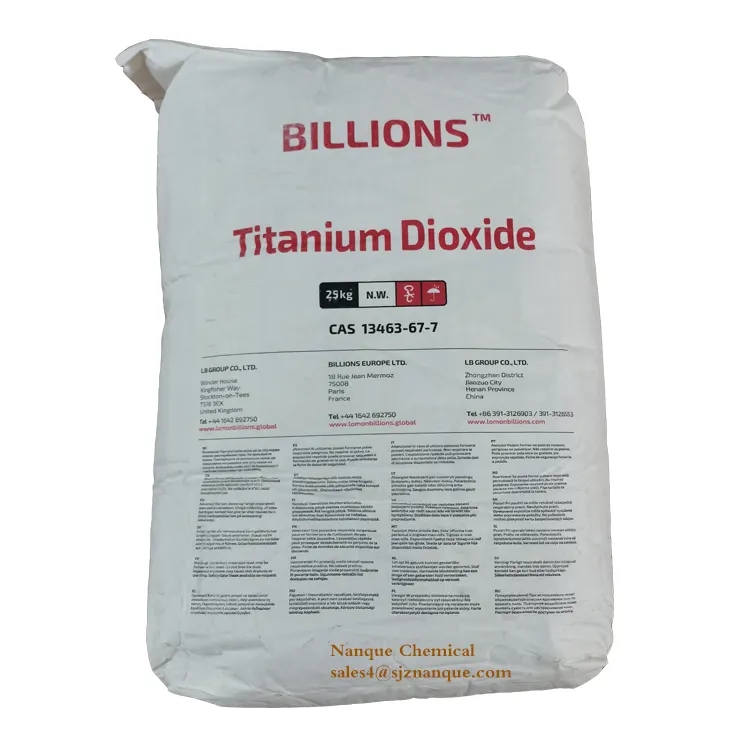

Pigment grade titanium dioxide is produced at a much larger particle size than nano grade. It is used as a colourant to whiten and brighten product formulations. Nano grade titanium dioxide is manufactured into very fine (nano) particles and is transparent and colourless. It is commonly used in sunscreens to provide effective protection from potentially harmful UV rays.

This route affords a product that is 29.4 wt % ZnS and 70.6 wt % BaSO4. Variations exist, for example, more ZnS-rich materials are produced when zinc chloride is added to the mixture of zinc sulfate and barium sulfide.

top sale dioxide titanium manufacturer. They have implemented strict environmental protocols and practices to minimize their impact on the environment, while also ensuring that their products are safe for consumers. Their commitment to sustainability has not only earned them the respect of their customers but also the trust of regulatory bodies and environmental organizations.

top sale dioxide titanium manufacturer. They have implemented strict environmental protocols and practices to minimize their impact on the environment, while also ensuring that their products are safe for consumers. Their commitment to sustainability has not only earned them the respect of their customers but also the trust of regulatory bodies and environmental organizations.Another challenge facing TiO2 industry suppliers is the increasing environmental regulations and sustainability requirements. The production of TiO2 can have environmental impacts, such as energy consumption and waste generation. Suppliers must invest in sustainable practices and technologies to minimize their environmental footprint and meet regulatory requirements.

It adds a bright white color to coffee creamers, baked goods, chewing gums, hard-shell candies, puddings, frostings, dressings, and sauces. But the nanoparticles found in “food-grade” titanium dioxide may accumulate in the body and cause DNA damage—which is one way chemicals cause cancer and other health problems.

The risks associated with titanium dioxide exposure depend on a variety of factors, including the form of the mineral, the route of exposure (such as being inhaled or consumed), and the duration and intensity of exposure.

Manufacturers of titanium dioxide play a crucial role in meeting the global demand for this versatile substance. They employ advanced manufacturing processes and technologies to produce high-quality titanium dioxide with consistent properties and performance. Many manufacturers also invest in research and development to explore new applications and improve existing products.

EFSA’s scientific advice will be used by risk managers (the European Commission, Member States) to inform any decisions they take on possible regulatory actions.

Titanium dioxide in food is used in a variety of products as a color enhancer. The most common foods containing titanium dioxide include:

Algaecidal effect of Lithopon: After 5 years of exposure to weathering in Alpen (Lower Rhine)

This article reviews the uses, benefits, and safety of titanium dioxide.

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments.

wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments. These manufacturers also work on enhancing the durability and performance of coatings, ensuring they can withstand harsh conditions and extend the lifespan of the coated surfaces These manufacturers also work on enhancing the durability and performance of coatings, ensuring they can withstand harsh conditions and extend the lifespan of the coated surfaces

These manufacturers also work on enhancing the durability and performance of coatings, ensuring they can withstand harsh conditions and extend the lifespan of the coated surfaces These manufacturers also work on enhancing the durability and performance of coatings, ensuring they can withstand harsh conditions and extend the lifespan of the coated surfaces coating raw material manufacturer.

coating raw material manufacturer.

The chemical is also found in common household and industrial products such as paints, coatings, adhesives, paper, plastics and rubber, printing inks, coated fabrics and textiles, as well as ceramics.

In 2023, California and New York proposed banning several food additives that are banned in Europe but legal in the United States. Titanium dioxide was among the five proposed to be banned, but in September, the additive was removed from the list of additives from the California ban list.

A 2023 study published in the journal Particle and Fibre Toxicology set out to examine the impact of titanium dioxide nanoparticles in mice “on the course and prognosis of ulcerative colitis,” by creating an ulcerative colitis disease model. Researchers found that the titanium dioxide nanoparticles significantly increased the severity of colitis. They also “decreased the body weight, increased the disease activity index and colonic mucosa damage index scores, shortened the colonic length, increased the inflammatory infiltration in the colon.” Researchers concluded: “Oral intake of TiO2 nanoparticles could affect the course of acute colitis in exacerbating the development of ulcerative colitis, prolonging the ulcerative colitis course and inhibiting ulcerative colitis recovery.”

To overcome this challenge, manufacturers use advanced technology and processes to monitor and control the buff percentage of their products. This may involve the use of sophisticated equipment to measure the coating thickness of titanium dioxide particles, as well as automated systems to adjust the level of coating as needed. By carefully controlling the buff percentage, manufacturers can ensure that their products meet the specifications of their customers and maintain a high level of quality and performance.

titanium dioxide application range manufacturer. Manufacturers add TiO2 to achieve a consistent white shade, which is essential for printing and writing purposes. Moreover, titanium dioxide helps improve the strength and smoothness of paper, resulting in higher quality products for consumers.

titanium dioxide application range manufacturer. Manufacturers add TiO2 to achieve a consistent white shade, which is essential for printing and writing purposes. Moreover, titanium dioxide helps improve the strength and smoothness of paper, resulting in higher quality products for consumers.