- However, like any mechanical part, the door sliding wheel requires maintenance. Regular cleaning and lubrication ensure the wheels roll smoothly, preventing unnecessary strain on the door and the track. In case of wear and tear, quick replacement is essential to prevent damage to the door or the frame.

- Another advantage of these roller systems is their compatibility with sensors and alarms. By integrating motion detectors or break-in sensors with the screen door, any unauthorized attempts to breach the door can trigger an alarm, alerting the homeowners and potentially scaring off intruders. This integration brings screen doors into the realm of proactive security measures, making them an active part of a layered security approach.

- The Symphony of Window Wheel Rollers

- Rust, scientifically known as iron oxide, forms when iron reacts with water and oxygen. This process, called oxidation, can weaken the structural integrity of the metal and alter its appearance. Wrought iron, being primarily iron, is susceptible to this natural process. However, the rate at which it rusts can vary greatly depending on factors such as the quality of the iron, the presence of protective coatings, and the environmental conditions it is subjected to.

If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free

If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free screen door wheel replacement.

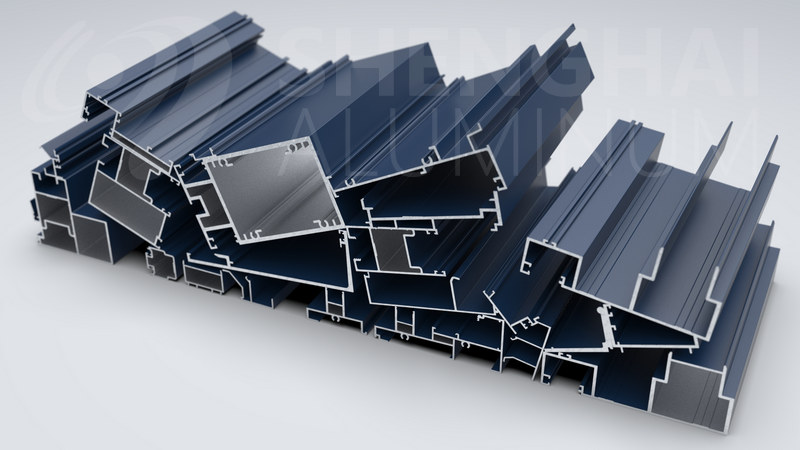

screen door wheel replacement.Our Aluminum Profiles For Doors And Windows Application

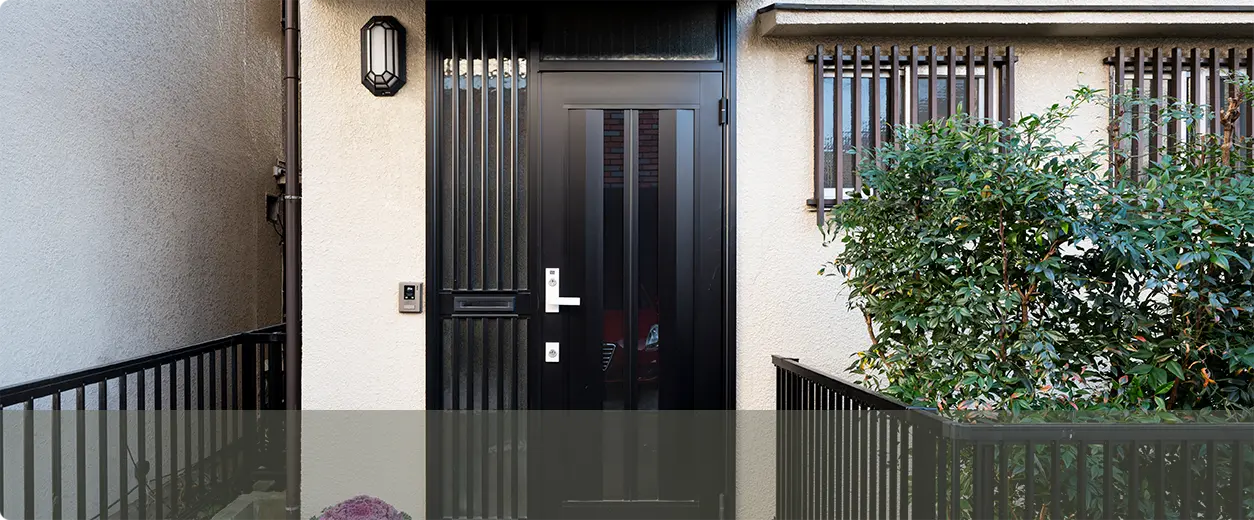

1. Aesthetic Appeal The slim design of these aluminium profiles contributes to a clean and modern aesthetic. They can seamlessly integrate into various decor styles while providing a contemporary edge. This makes them particularly appealing for residential, commercial, and retail environments, where design plays a crucial role in attracting customers.

- Traditional These gates often feature classic designs with ornate details, making them ideal for historic homes.

Ideally, the more the pressure, the greater the extrusion it can produce. The machine applies the initial pressure crushing the billet against the die.

At Orion Ornamental Iron Inc., they specialize in creating custom iron products that add beauty, elegance, and security to any property. Their team of skilled craftsmen uses the finest materials and innovative techniques to design and fabricate iron products that are both aesthetically pleasing and durable.

This is regarded as the easiest and fastest way to fix different aluminum profiles.

The process of welding metal leaves requires a high level of precision and skill. Due to their thinness, they can easily distort or burn through under intense heat, making the welding process a delicate balancing act between power and control. TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, with their ability to provide precise control over the heat source, are commonly employed for such tasks. The use of protective gases helps to prevent oxidation and maintain the integrity of the metal leaves during the process.

metal leaves for welding

We’ve explored the ins and outs of aluminum vs wrought iron fences, diving into aspects like aesthetics, durability, cost, security, and maintenance.

Profilati Alluminio manufactures and ships worldwide – thus in the U.S. too – various types of aluminum extrusions also with extremely small dimensional tolerances: among them, aluminum window extrusion profiles.

These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations

These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations outdoor metal storage box with lock. Their compact design makes them easy to transport and store, allowing you to keep your belongings organized and easily accessible when needed.

outdoor metal storage box with lock. Their compact design makes them easy to transport and store, allowing you to keep your belongings organized and easily accessible when needed.Our unique climate in Southern California can take a toll on our iron fences, as they are constantly exposed to humidity and moisture in the air, making iron victim to the process of oxidation. Over time, your iron fence will show the signs of oxidation with rust patches. Rust is the number one enemy of iron fences, and needs to be removed on the first signs of its appearance. This can be accomplished using a fine wire brush. Make sure to lay a tarp beneath the wrought iron fence to catch flakes, wear gloves, and carefully brush away all points of rust along the fence, paying special attention to the post and joints.

This may seem like a small and unimportant item, but shortcuts here can make a nice iron fence or gate look cheap. Pay attention to the smaller elements like the brackets that connect the iron fence to the posts, the post caps and decorative finials on top of the pickets.

Furthermore, advancements in technology have expanded the possibilities for creating these ornamental pieces. Modern techniques, including CNC machining and 3D modeling, allow for precise and intricate designs that were once unimaginable. This blend of traditional and contemporary methods ensures that rod iron scrolls remain relevant and sought after in today's design landscape.

Extruded aluminum is about 1/3 less than iron or brass, a clear indication it is comparatively a lightweight material.

The aluminum profiles for doors and windows are made of 6-series aluminum alloy, and the aluminum-magnesium silicon is the main element of the 6-series aluminum alloy, and each element has a certain range of content. However, the price of various elements is inconsistent, and the lack of precious metal content is a major cause of poor profile quality. Only in strict proportion then can produce aluminum extrusions of excellent quality. The prepared raw materials are placed in an aluminum melting furnace to be melted, slag is discharged, cooled, and then cast aluminum ingots or bars are used for the production of aluminium profiles. If the exhaust is not ideal, the air bubbles in the aluminium profile will cause defects. The aluminium profiles for doors and windows are mainly made of 6063 grade aluminum alloy. If the aluminum extrusion manufacturer uses the national standard 6063 aluminum ingot, it will be guaranteed in terms of raw material quality.