- In addition to their efficiency, automatic bag closing systems are known for their versatility and adaptability. These systems can handle a wide range of bag sizes, from small pouches to large sacks, and can work with a variety of materials, including plastic, paper, and woven fabrics. This flexibility allows companies to streamline their packaging operations and accommodate different product needs, all with a single system.

Investing in the right sewing machine for boat upholstery can elevate your projects and ensure they stand the test of time against the elements. By considering features like a powerful motor, heavy-duty construction, and specialized feet, you can make an informed choice that will enhance your sewing experience. With the right tools at your disposal, transforming your boat's interior can be an enjoyable and rewarding endeavor.

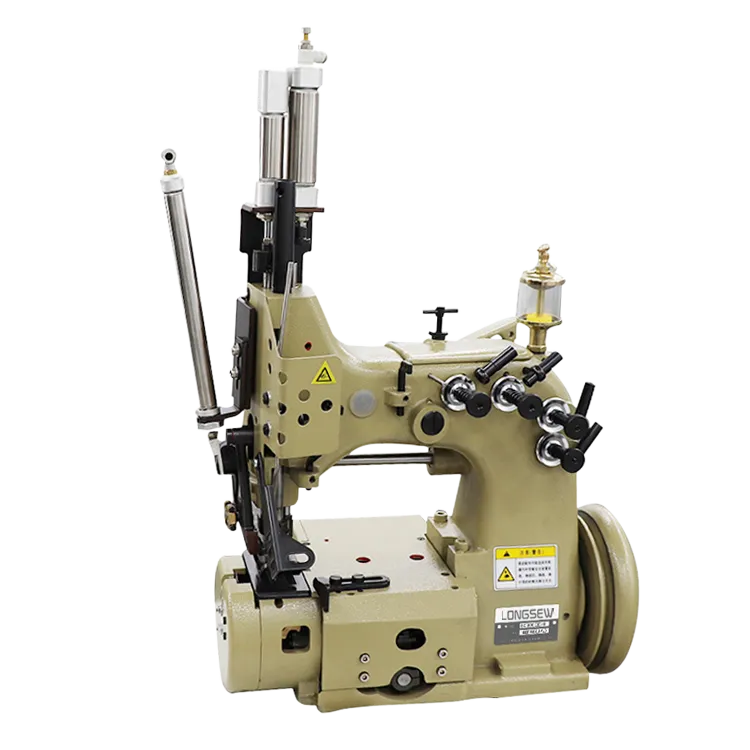

Jumbo bag sewing machinery is specifically designed to meet the challenges of assembling large and heavy-duty bags. Typical sewing machines operate at high speeds and can handle the tough, thick materials used in jumbo bags. This machinery not only increases production efficiency but also ensures that the seams are durable and reliable, which is essential for the safety and integrity of the contents being transported.

Tools of the Trade

- Motor Power Look for machines with strong motors that can handle heavy materials without slowing down or jamming.

With all that being said, we are happy to be experiencing the new wonders of technology, even when it comes to quilting and sewing. Choosing the best heavy duty sewing machine for home use can be a difficult process, but we hope that our little piece of advice will make it a lot easier to find the perfect tools for you!

Moreover, the zigzag stitch can be utilized in decorative sewing techniques, such as applique and free-motion embroidery, allowing sewists to not only construct but also embellish their work creatively. This machine serves as a bridge between function and artistry, facilitating the creation of unique, personalized pieces.

The Pricing Landscape of Auto Sewing Machines

- Enhanced Production Capacity With faster processing times, manufacturers can scale up production, catering to larger orders and meeting the demands of various industries.

3. Easy Navigation The markings on the foot help sewers maintain consistency, especially when sewing intricate patterns or when sewing multiple layers of fabric.

E. Maintaining and Troubleshooting Your Machine:

In this part, we’ll cover routine machine maintenance, such as cleaning and oiling, to ensure smooth operation. We’ll also address common troubleshooting problems and provide solutions to help readers resolve issues on their own.

Advantages of Using a Double Stitch Machine

The Ultimate Guide to Heavy-Duty Sewing Machines for Thick Leather

4. Threading the Needles Thread each needle separately, following your machine's threading path. Be careful to ensure that both threads run smoothly and don't tangle. It is often useful to use a lighter thread in the bobbin to avoid visibility issues.

how to use twin needle on sewing machine

In the textile and packaging industries, the production of polypropylene (PP) bags has gained immense popularity due to their durability, versatility, and cost-effectiveness. With the increasing demand for these eco-friendly bags, the need for efficient and high-quality manufacturing processes has become paramount. One significant advancement in this field is the introduction of the PP bag silai machine, which has revolutionized how these bags are produced. This article explores the key features and benefits of PP bag silai machines, highlighting their importance in modern manufacturing.

These are heady days for anyone in the home improvement and DIY industries, and our newfound national obsession with crafts and skills has not spared the sewing business. I had time to ponder this during the hour and a half I spent on hold waiting to speak with a human being at the Singer Sewing Machine Company a couple of weeks ago.

Bag making machines come in various types, each designed to produce different kinds of bags. Some popular types include flat bag making machines, drawstring bag machines, and shopping bag making machines. Each machine is engineered to cater to specific requirements in terms of size, material, and design. Over the years, technological advancements have made these machines faster and more accurate, thus reducing production time and increasing output.

Modern industrial leather sewing machines are equipped with specialized features such as walking feet, which help move the thick material smoothly through the machine. They also typically possess a powerful motor capable of stitching through multiple layers of leather without skipping stitches. This evolution has made it possible for manufacturers to produce leather goods more efficiently while maintaining high standards of quality.

What Can I Do with an Overlocker?

3. Versatility Modern auto cutter sewing machines can handle a variety of materials, including delicate fabrics, heavy-duty textile, and layered materials. This versatility allows manufacturers to produce diverse clothing lines, from casual wear to formal attire, without needing extensive manual adjustments or multiple machines.

auto cutter sewing machine

At its core, the zig zag stitch machine combines the basic features of traditional sewing machines with the added functionality of creating a zig zag pattern. This unique stitch is formed by the machine's needle moving side to side while also stitching forward, allowing seamstresses to produce a variety of stitch widths and lengths. The adjustable settings on a zig zag stitch machine allow for customization, making it suitable for different types of fabric and sewing projects.

For quilting enthusiasts and professionals alike, a heavy-duty quilting sewing machine is an invaluable tool that makes the process of creating beautiful quilts more efficient and enjoyable. These machines are designed to handle thicker fabrics and multiple layers, providing the power and durability needed for heavy-duty sewing projects. In this article, we’ll explore the key features, benefits, and tips for selecting the perfect heavy-duty quilting sewing machine.

At the core of the double needle chain stitch sewing machine lies its unique threading system. Unlike conventional sewing machines that use a single needle and bobbin mechanism, the double needle machine operates with two needles threaded simultaneously. These needles penetrate the fabric and form a chain stitch, which is a type of stitch characterized by its interlocking loops. The two needles work in tandem to create parallel rows of stitching, resulting in a strong seam that can withstand stress and strain.

Advantages of the Double Needle Feature

Conclusion

The primary advantage of using a walking foot is the improved fabric control it provides. When working with thick fabrics, the risk of uneven sewing increases due to the bulk of the material. A walking foot helps to maintain an even stitch length, minimizing the risk of puckering or distortion that can occur when multiple layers are sewn together.

The invention of the PP bag stitching machine, specifically, provided manufacturers with a fast and efficient way to produce and close bags. These machines evolved from simple stitching devices to sophisticated models equipped with features such as adjustable stitching lengths, automatic tension control, and high-speed operations. Modern machines offer increased efficiency, with some able to stitch thousands of bags per hour, thereby significantly enhancing productivity.

Solution: Regularly clean the machine, ensuring the area around the needle and feed dogs is free from lint, dust, or fabric remnants. As per the manufacturer’s instructions, oiling the machine will also ensure that its parts move smoothly. It’s also advisable to periodically check for worn-out components, like needles, and replace them promptly. Using a sharp needle for light fabrics can significantly affect the sewing outcome.

In the landscape of textile production, the evolution of sewing technology has had a profound impact on efficiency, creativity, and quality. Among the myriad of sewing machines available today, the modern chain stitch machine stands out as a key player. This innovative machine not only enhances the speed of production but also elevates the quality of finishing in garment manufacturing, making it an indispensable tool in the fashion and textile industries.

B. Leatherwork and Accessories:

Readers will discover ideas for crafting leather bags, wallets, belts, and other accessories using thecapabilities of a heavy duty sewing machine.

Ultimate Guide to Heavy Duty Sewing Machines

- Walking Foot Mechanism A walking foot is essential for sewing multiple layers of leather, as it helps maintain even tension across the fabric. This feature can prevent puckering and ensure a smooth finish.

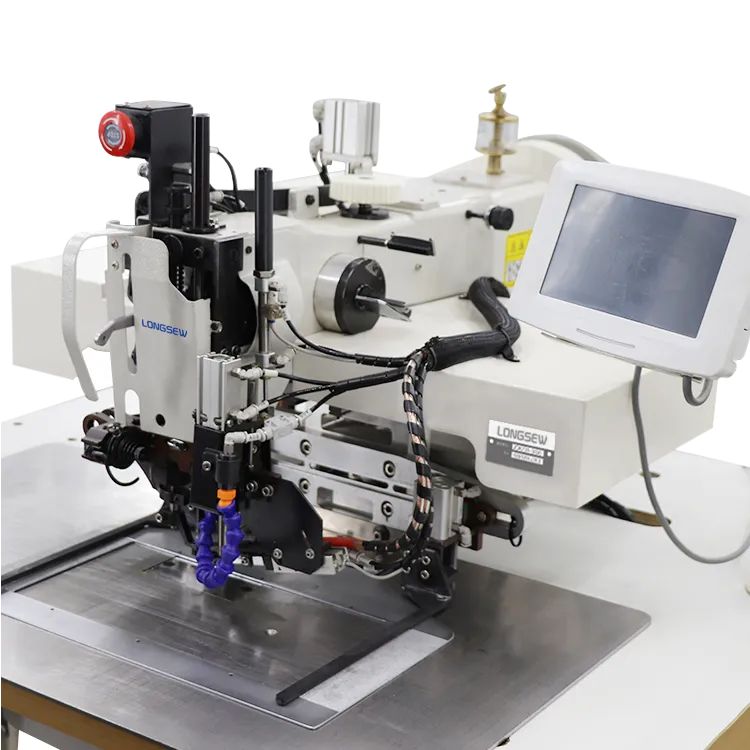

Auto sewing machines have gained immense popularity due to their ability to streamline the sewing process. Unlike traditional machines, which require manual operation, auto sewing machines come equipped with advanced features that automate various sewing tasks. These machines can perform multiple functions, such as threading, cutting, and even embroidering, with minimal human intervention. This automation leads to increased productivity and consistent quality, making auto sewing machines a desirable investment for many.

The price of fully automatic sewing machines can vary widely based on brand, features, and functionality. Entry-level models can be found for as low as $200, which are typically suitable for beginners or those who sew occasionally. These models offer essential features like basic stitch patterns and automatic needle threading but may lack the advanced functionalities found in higher-end machines.

The inclusion of features such as automatic thread cutting and tension control not only enhances precision but also reduces manual intervention, contributing to a more streamlined workflow. Furthermore, the integration of digital technology enables real-time monitoring and maintenance, allowing operators to identify and rectify issues before they lead to significant downtime. Environmental considerations have also influenced the design and functionality of these machines, with newer models emphasizing energy efficiency and the use of sustainable materials for components. As industries continue to evolve, the demand for bag closing sewing machines is set to rise, driven by the need for efficient and reliable packaging solutions.

Another vital aspect to consider is the learning curve involved with your chosen sewing machine. Handheld sewing machines tend to have a shorter learning curve, making them ideal for beginners. Their simplicity and user-friendly design allow you to get started with sewing basics right away.

The mechanism behind a lock stitch is quite fascinating. When you engage the sewing machine, the needle thread passes through the fabric. As the needle descends, the bobbin case rotates and the bobbin thread is pulled up through a small opening. This interlocking action occurs as the needle rises again, creating a tight, locked seam. The configuration of these threads and their interaction with the fabric results in a stitch that is flat on one side (the top side where the needle is) and slightly bulkier on the other side (the bobbin side).

- Brand Reputation Invest in machines from reputable manufacturers known for quality and reliability. Research customer reviews and feedback to gain insights into the performance of the models you’re considering.