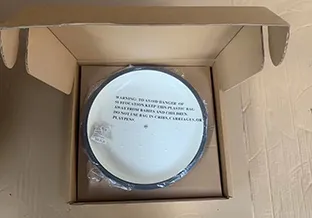

7 hole egg pan

A cast iron griddle with holes is specifically designed to provide even heat distribution while allowing excess fat and grease to drain away. The holes in the griddle serve a dual purpose they help release moisture, which prevents your food from becoming soggy, and they facilitate healthier cooking by allowing excess oils to drain. This design is particularly ideal for preparing various types of dishes, including vegetables, grilled meats, and even pancakes.

Cast iron cookware can be traced back centuries, and its enduring appeal lies in its unique cooking properties. Unlike other materials, cast iron distributes heat evenly, making it ideal for various cooking methods, including frying, baking, and sautéing. Moreover, it develops a natural non-stick surface when seasoned properly, which enhances the flavor of dishes over time. This heritage and functionality have led to a revival of interest in cast iron pots, pans, and Dutch ovens.

Another significant benefit of cast iron is its durability. Cast iron cookware is built to last for generations, making it a worthwhile investment for any outdoor cook. With proper care, it can endure the elements and the wear and tear of camping trips. Unlike some modern cookware that may chip or warp, a well-maintained cast iron skillet or Dutch oven can become an heirloom item, passed down through families. Over time, the seasoning on the cookware improves, providing a natural, non-stick surface that enhances flavors.

In conclusion, a pre-seasoned cast iron pizza pan is an excellent investment for anyone who loves making pizza at home. Its superior heat retention, natural non-stick surface, and flavor-enhancing qualities make it a must-have in any kitchen. With its versatility and easy maintenance, it’s not just a pan for pizza; it’s a multipurpose cooking tool that will undoubtedly elevate your culinary creations. So, whether you’re a seasoned chef or a home cook, consider adding a pre-seasoned cast iron pizza pan to your kitchen arsenal and enjoy the delightful results it brings to your pizza night!

Cooking with a skillet pan grill is incredibly convenient. Most models are compatible with various heat sources, including induction, gas, and electric cooktops, and many are oven-safe as well. This adaptability means you can start your meal on the stovetop to achieve that perfect sear and then transfer it to the oven to finish cooking, all in the same pan. This method optimizes the flavors and helps achieve more consistent results.

Hollantilaisessa padassa voi valmistaa monenlaisia ruokia. Perinteiset pataruoat, kuten goulash, patee ja erilaiset kasvisruoat, ovat kaikki helposti valmistettavissa. Padan käyttö ei kuitenkaan rajoitu pelkästään lihan tai vihannesten kypsentämiseen. Hollantilainen pata on myös erinomainen valinta leivontaan; monilla on kokemuksia maukkaista leivistä ja piirakoista, jotka on paistettu juuri oikeassa lämpötilassa.

Moreover, cleaning up after a meal in a 4.5-quart camp oven is relatively simple if proper care is taken. Regular seasoning of the cast iron helps maintain its non-stick surface and prevents rust, ensuring it remains a reliable cooking companion for many camping trips to come.

6. Clean the Surfaces Thoroughly clean the cylinder and piston rod surfaces to ensure that no debris or remnants of the old seal remain.

The applications for oil seals span numerous industries, from automotive to industrial machinery. In the automotive sector, for example, oil seals are essential in engines and transmission systems, where they function to prevent oil loss and contamination. In industrial machinery, they protect bearings and other critical components, ensuring smooth operation and protecting against damage from foreign particles.

The importance of wiper oil seals cannot be overstated. In automotive applications, for instance, these seals help maintain the integrity of the engine, transmission, and other critical systems. If an oil seal fails, it can lead to significant oil leaks, resulting in insufficient lubrication and leading to mechanical failures. Furthermore, oil leaks can create hazardous situations, such as slick surfaces on roads or contamination of nearby soil and water sources.

To avoid these issues, it is imperative to inspect the seals regularly and replace any worn or damaged components as part of routine maintenance. A hydraulic ram seal kit offers a convenient way to procure all necessary seals at once, simplifying the maintenance process.

Conclusion

hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.

hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.2. SKF Group - Founded in Sweden, SKF is a global leader in bearings and seals. They offer a wide range of oil seals designed for different applications, backed by extensive research and development efforts. Their commitment to quality and sustainability has made them a preferred choice among manufacturers.

By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs

By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs seal kit cylinder.

seal kit cylinder.In conclusion, hydraulic cylinder seal kits by size are essential components for maintaining and rebuilding hydraulic cylinders in various industries. By selecting the right size seal kit, accurately measuring your cylinder, following the manufacturer's instructions, and using high-quality seals, you can ensure the proper functioning and longevity of your hydraulic cylinders. Investing in seal kits can help you avoid downtime, leaks, and costly repairs, making them a valuable asset for any operation that relies on hydraulic equipment.

Regular maintenance of the rear axle system, including checking the condition of the rear hub seal, is essential for ensuring the longevity and efficiency of a vehicle. It is recommended to have the rear hub seal inspected during routine service intervals or if any of the aforementioned symptoms are present. By addressing any issues with the rear hub seal promptly, car owners can prevent costly repairs and ensure the safety and performance of their vehicle.

- Apply lubrication: Apply a compatible lubricant to the sealing components to aid in installation and ensure proper sealing.

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs

They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs They also help maintain lubricant quality, reducing the frequency of maintenance and replacement costs dust lip seal.

dust lip seal.

Applications in Various Industries

A comprehensive hydraulic cylinder seal kit typically includes

A hydraulic pump seal kit is a collection of seals, O-rings, and other components designed to prevent fluid leakage from hydraulic pumps. Seals are crucial because they contain the hydraulic fluid under pressure, ensuring optimal performance while preventing contamination and loss of fluid. The kit typically includes various sized seals and other components specifically curated to fit a particular pump model.

Furthermore, maintaining hydraulic seals can save money in the long run. Downtime caused by hydraulic failures can be costly, not just in terms of repairs but also in lost productivity. By routinely checking and replacing seal kits as part of regular maintenance schedules, equipment owners can minimize unexpected breakdowns and improve the reliability of their machinery.

Applications

Understanding the 20x35x7 Oil Seal Importance and Applications

Hydraulic gear pump seal kits are essential for maintaining efficient and reliable operation in hydraulic systems. By understanding their components and following best practices for installation and maintenance, operators can extend the lifespan of their pumps and prevent costly breakdowns. Regular care and timely replacement of seals will ensure optimal performance, contributing to the overall efficiency and productivity of hydraulic applications. Investing in quality seal kits and implementing thorough maintenance practices is a fundamental strategy for anyone working with hydraulic systems.

3. Pressure and Temperature Ratings These oil seals are engineered to endure a range of pressures and temperatures, making them suitable for both high-pressure hydraulic systems and standard mechanical applications. The capability of withstanding extreme conditions allows for versatility across different sectors.

4. Reassembly After replacing the seals, reassemble the hydraulic cylinder carefully. Ensure that all components are aligned correctly and that no foreign objects are present. It’s vital to follow the correct torque specifications and procedures to prevent any damage during reassembly.

2. Design Specifications The unique design aspects, such as the sealing lip geometry and the hardness of the rubber, are optimized to balance flexibility and resilience. This design ensures proper contact with the shaft, reducing the risk of oil leakage and improving the overall efficiency of the machinery.

4. Extended Equipment Lifespan The lifespan of machinery is heavily influenced by the condition of its components. Regularly replacing worn cylinder seals prolongs the life of hydraulic systems, which translates to better return on investment. By maintaining these parts, organizations can ensure that their capital assets remain productive for longer periods, maximizing their operational efficiency.