Rubber type

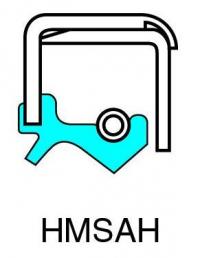

1. Sealing Element

Sometimes, two different kinds of fluids leak from one chamber to another and gets mixed up. Here, this type comes as a boon. This is a metal inserted duplex type oil seal recommended on such assembly where mix-up of two different fluids is to be prevented.

In the UK, customers have a range of options for purchasing oil seals. There are several reputable UK gasket manufacturers that offer a wide selection of oil seals to meet various industrial needs.

Oil Seals 101 – The Ultimate Guide

spark plug 794 055a. Gather the necessary tools You will need a socket wrench, a torque wrench, and a spark plug gap tool.

spark plug 794 055a. Gather the necessary tools You will need a socket wrench, a torque wrench, and a spark plug gap tool.Standard 3760/3761

8 tips to keep in mind when installing or replacing oil seals

Table 8: Housing design checklist

However, the new variant also comes with less good properties. Namely less flexibility and less resistance during assembly. Most damages therefore occur during the installation of PTFE oil seals.

Of course, all rubber materials and seals will provide a range of benefits; however, you will need to consider chemical compatibility, sufficient temperature ranges, pressure ranges, and more.